Transformer oil tank capable of facilitating drainage and adjusting liquid level in real time

A transformer oil tank, real-time adjustment technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of reduced insulation of transformer insulating parts, poor cooling conditions, and inability to cool oil cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

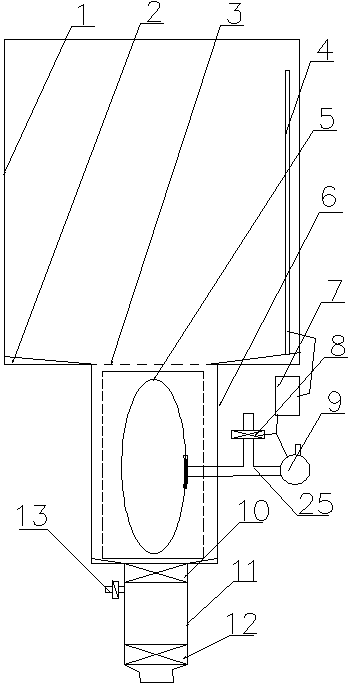

Embodiment 1

[0027] Embodiment 1: as figure 1 , 4As shown, a transformer oil tank that is convenient for drainage and real-time adjustment of the liquid level includes a tank body 1, an oil storage tank 6 connected to the tank body 1 is arranged under the tank body 1, and a connected water storage mechanism is arranged under the oil storage tank 6, so that The air bag 5 is arranged in the oil storage tank 6, and the air bag 5 communicates with the three-way valve 25 through the conduit passing through the oil storage tank. The other two ends of the three-way valve 25 are connected with a solenoid valve 8 and an electric pump 9. The pumps 9 are all connected to the programmable controller 7, and the programmable controller 7 is connected to the liquid level sensor 4 in the tank 1 through a signal line.

[0028] The water storage mechanism is a water storage cylinder 11 arranged under the oil storage tank 6 and communicated with the oil storage tank 6 , and the upper and lower ends of the w...

Embodiment 2

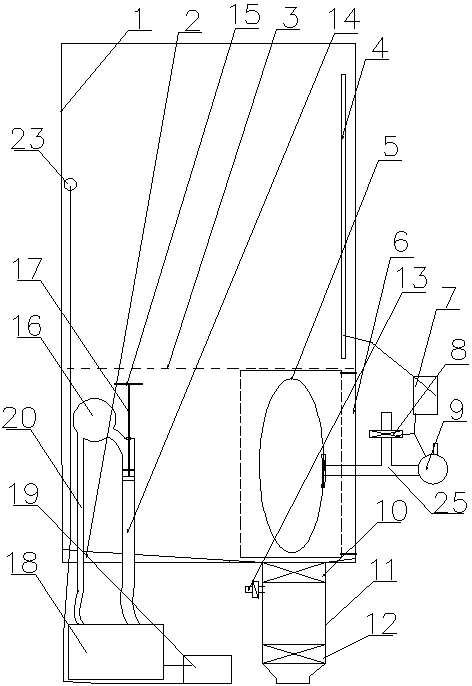

[0034] Embodiment 2: as figure 2 , 4 As shown, a transformer oil tank that is convenient for drainage and real-time adjustment of the liquid level includes a tank body 1, an oil storage tank 6 connected to the tank body 1 is arranged under the tank body 1, and a connected water storage mechanism is arranged under the oil storage tank 6, so that The air bag 5 is arranged in the oil storage tank 6, and the air bag 5 communicates with the three-way valve 25 through the conduit passing through the oil storage tank. The other two ends of the three-way valve 25 are connected with a solenoid valve 8 and an electric pump 9. The pumps 9 are all connected to the programmable controller 7, and the programmable controller 7 is connected to the liquid level sensor 4 in the tank 1 through a signal line.

[0035] The water storage mechanism is a water storage cylinder 11 arranged under the oil storage tank 6 and communicated with the oil storage tank 6 , and the upper and lower ends of the...

Embodiment 3

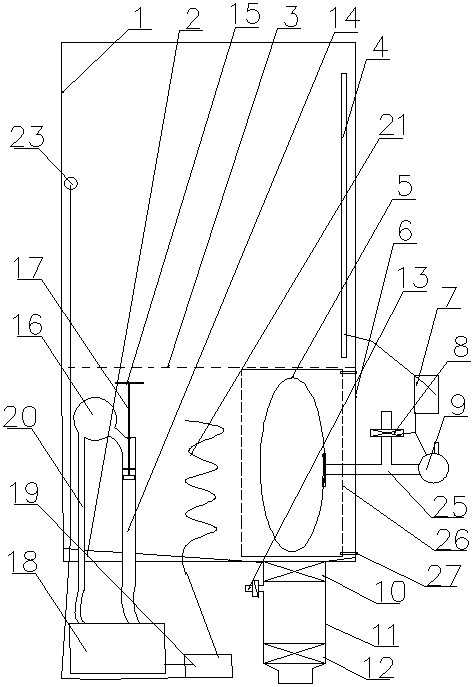

[0044] Embodiment 3: as image 3 , 4 As shown, a transformer oil tank that is convenient for drainage and real-time adjustment of the liquid level includes a tank body 1, an oil storage tank 6 connected to the tank body 1 is arranged under the tank body 1, and a connected water storage mechanism is arranged under the oil storage tank 6, so that The air bag 5 is arranged in the oil storage tank 6, and the air bag 5 communicates with the three-way valve 25 through the conduit passing through the oil storage tank. The other two ends of the three-way valve 25 are connected with a solenoid valve 8 and an electric pump 9. The pumps 9 are all connected to the programmable controller 7, and the programmable controller 7 is connected to the liquid level sensor 4 in the tank 1 through a signal line.

[0045] The water storage mechanism is a water storage cylinder 11 arranged under the oil storage tank 6 and communicated with the oil storage tank 6 , and the upper and lower ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com