Ultra-violet LED face light source for PCB exposure machine

An LED surface light source, ultraviolet technology, applied in the direction of plane light source, light source, electric light source, etc., can solve the problems of easy explosion, high pollution, high cost of use, and achieve the effect of concentrated irradiation spot, high energy uniformity, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

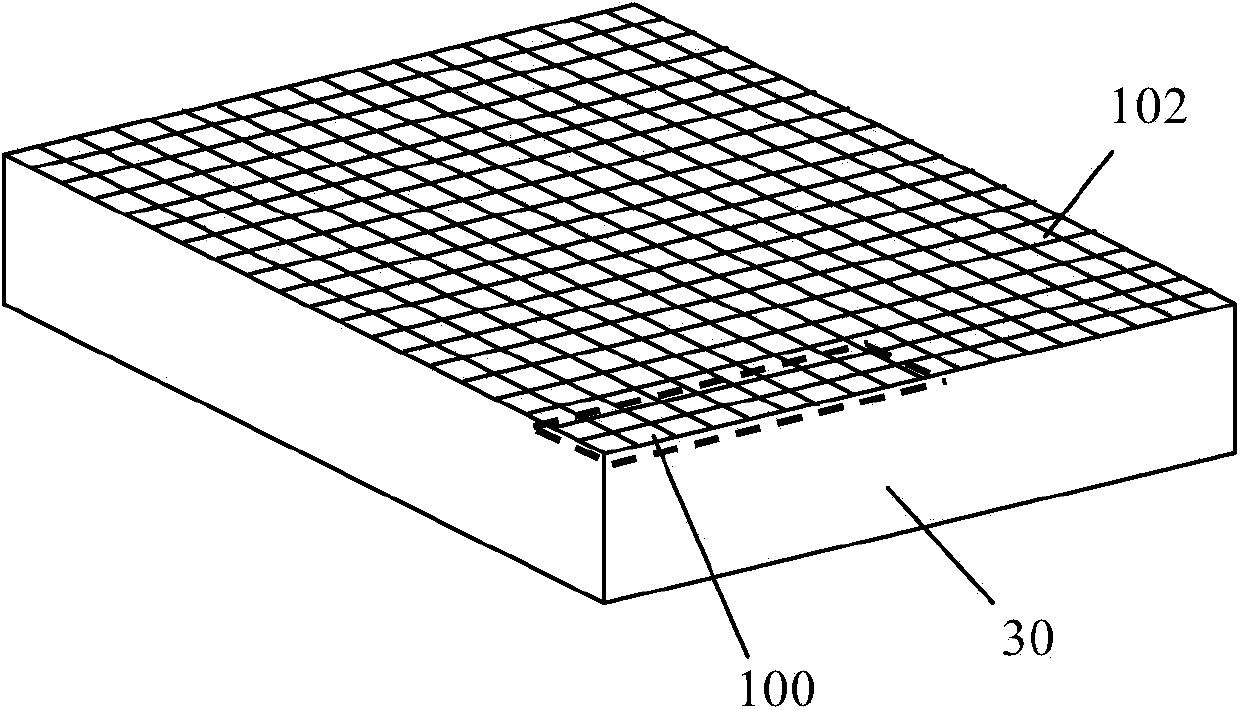

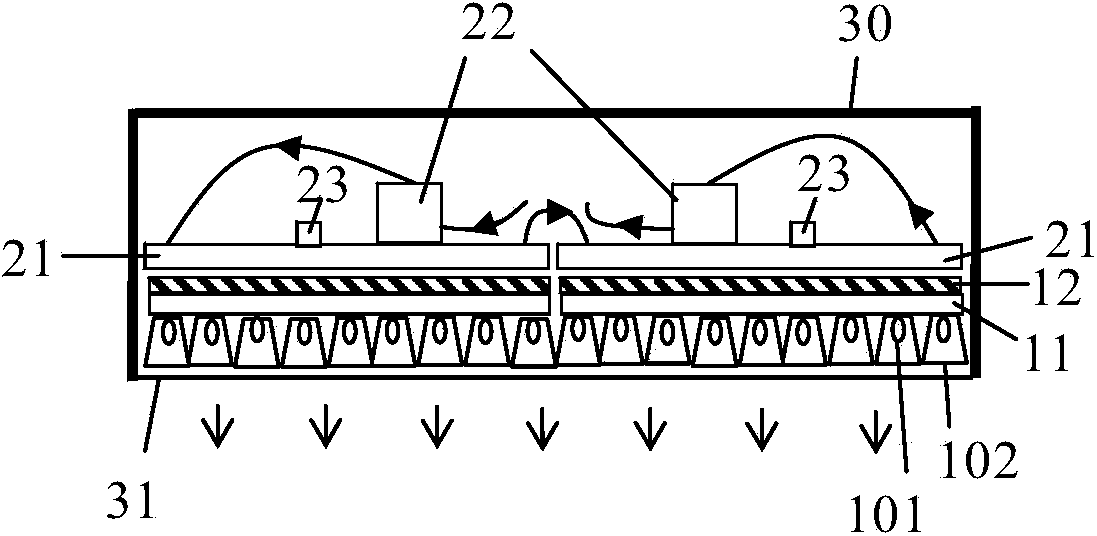

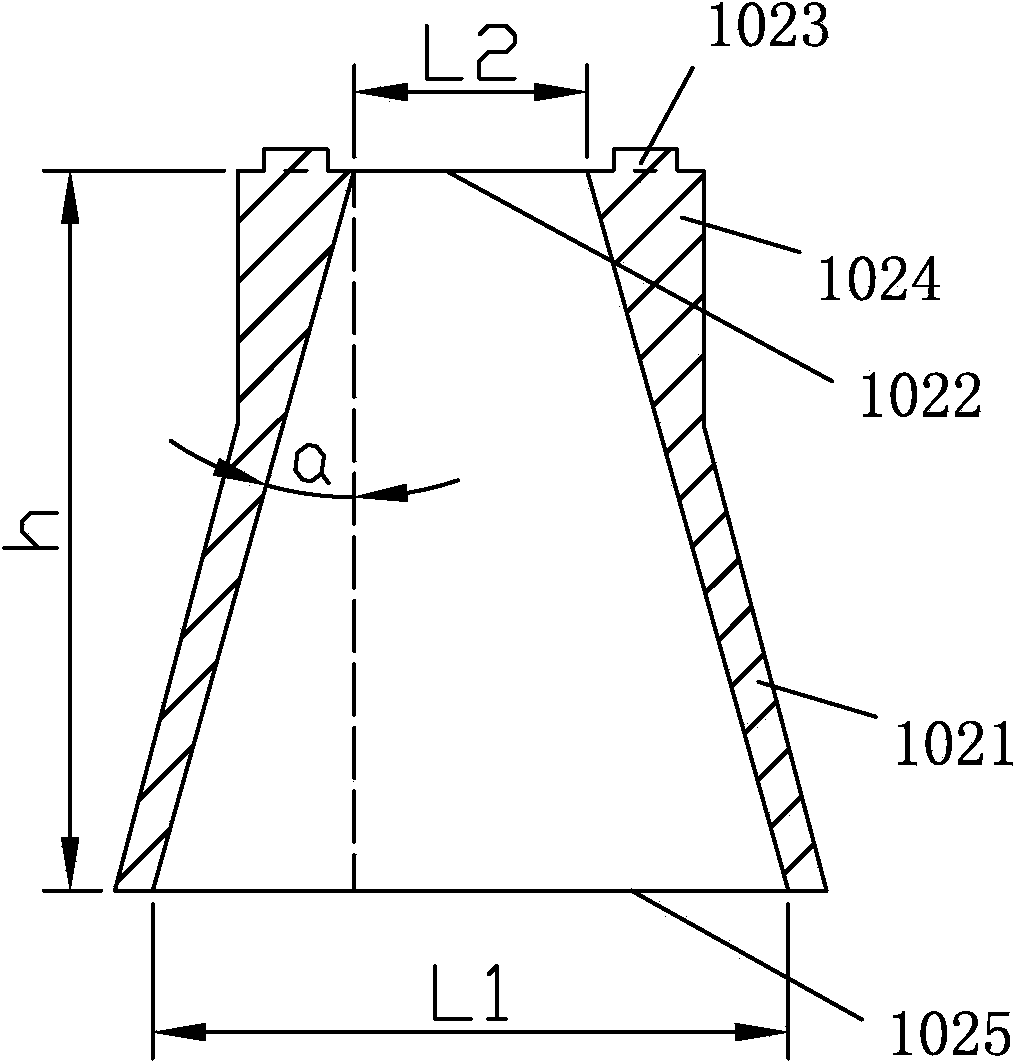

[0040] like Figure 1 to Figure 10 As shown, the ultraviolet LED surface light source for PCB exposure machine of the present invention includes a plurality of water-cooled ultraviolet LED light box units, wherein: for each of the water-cooled ultraviolet LED light box units, each of the water-cooled ultraviolet LED light box units includes On the component mounting surface of 12, there are M×N ultraviolet LED lamp beads 101 arranged in a matrix structure, M and N are positive integers greater than 0, and M and N are generally not 1 at the same time, and all the ultraviolet LED lamp beads 101 are connected in series After that, it is connected with the ultraviolet LED surface light source control device (not shown) through the power lead interface (not shown in the figure, which can be arranged on the outer cover 30), and each of the ultraviolet LED lamp beads 101 is covered with a reflector Cup 102, all the reflective cups 102 are installed on a reflective cup mounting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com