Comprehensive Mechanized Filling Coal Mining Goaf Roof Dynamic Monitor

A comprehensive mechanized and filling coal mining technology, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problem of inability to measure the subsidence, and achieve the effect of reducing the difficulty of measurement, simple application and accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

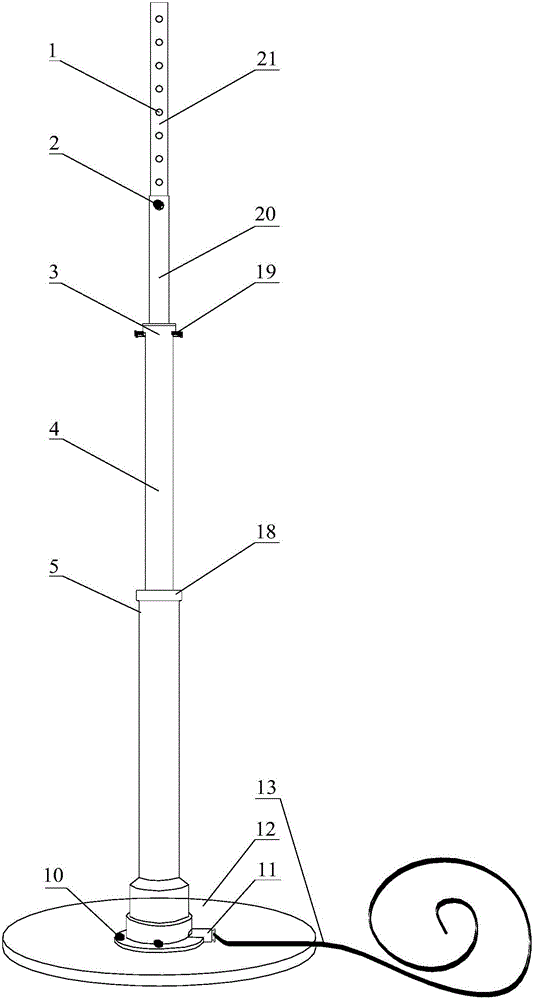

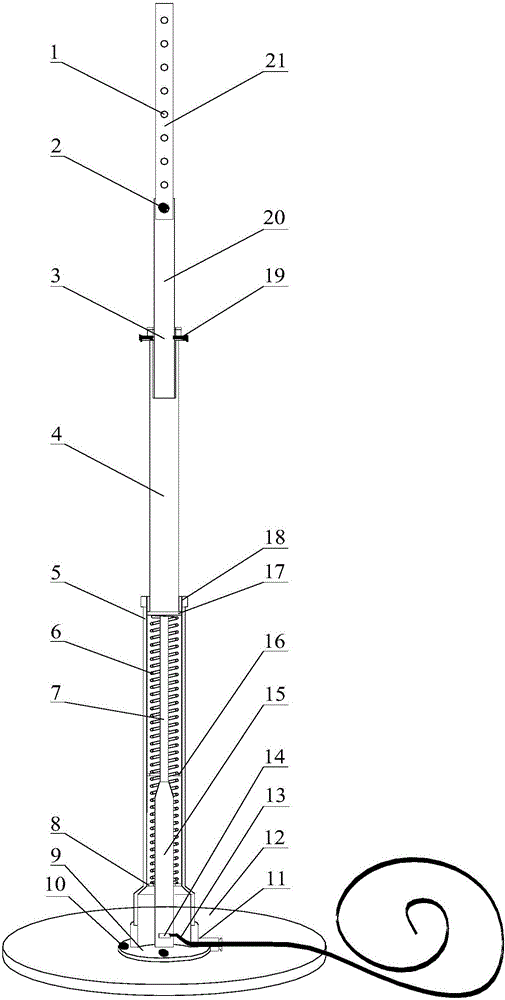

[0023] figure 1 As shown, the comprehensive mechanized filling coal mining goaf roof dynamic monitor of the present invention is mainly composed of a monitoring assembly and a multi-stage telescopic rod; the monitoring assembly includes a chassis 12, a displacement meter support 9 arranged on the chassis 12, a displacement meter The base cylinder 5 is provided with a base cylinder 5, the base cylinder 5 is provided with a multi-stage telescopic rod, the base cylinder 5 is provided with a spring support 8 and a grating displacement meter 15 inserted in the spring support 8, so The grating displacement meter 15 described above includes four parts: a scale grating, an indicating grating, an optical system and a measuring system. When the scale grating moves relative to the indicating grating, it forms moiré fringes that are distributed roughly according to a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com