A micro-nano bubble treatment device and operation method for liquefiable foundation

A technology of micro-nano bubbles and liquefied foundations, which is applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as the inability to use existing building foundations, limited depth of reinforcement by dynamic compaction, and damage to buildings due to vibration, and achieve improved Anti-liquefaction ability, saving resources, and increasing the effect of shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

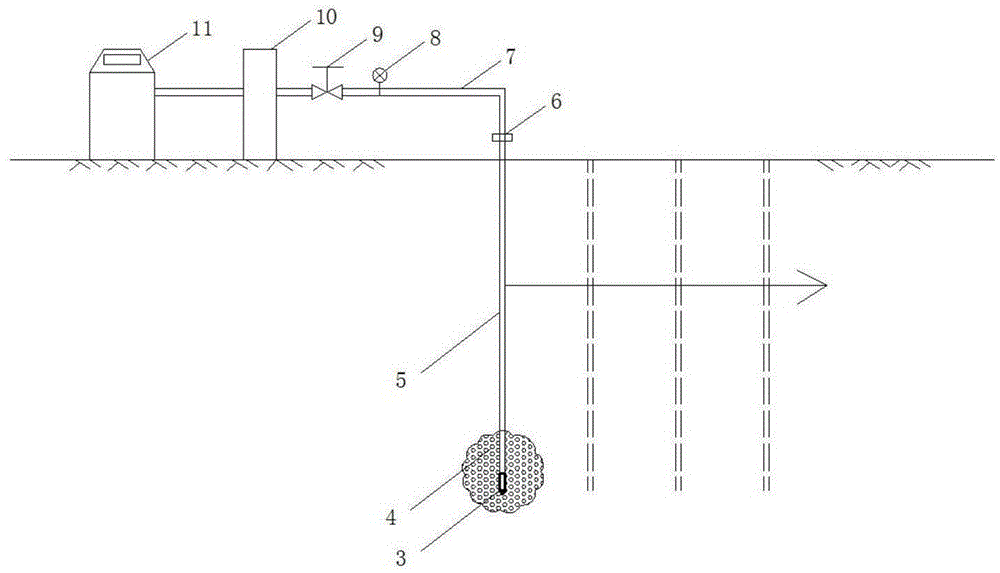

[0033] Embodiment 1: A kind of micro-nano bubble treatment can liquefy foundation and thereby strengthen the operation method of new building foundation, such as figure 2 As shown, the operation steps are as follows:

[0034] 1) According to the geological survey results, the position and depth of the liquefiable sand layer of the foundation are understood, and the drilling depth of the hollow drill pipe 5 is determined;

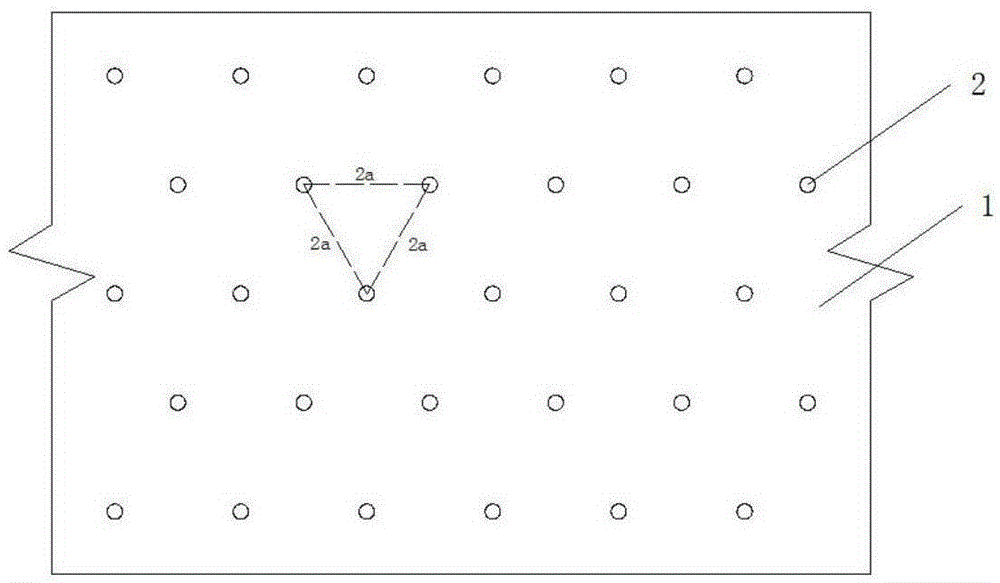

[0035] 2) Drilling positioning: such as figure 1 As shown, the boreholes 2 are arranged in a quincunx shape on the area to be reinforced 1, and the distance between the boreholes 2 is 3-4m;

[0036] 3) Embedding the jet head: use a drilling rig to vertically drive the hollow drill pipe 5 with the air jet head 3 into the bottom of the liquefiable sand layer of the foundation, remove the drilling rig, and expose the top of the hollow drill pipe 5 to the surface;

[0037] 4) The setting of the jet system: Utilize the air duct 7 to connect the hollow drill pi...

Embodiment 2

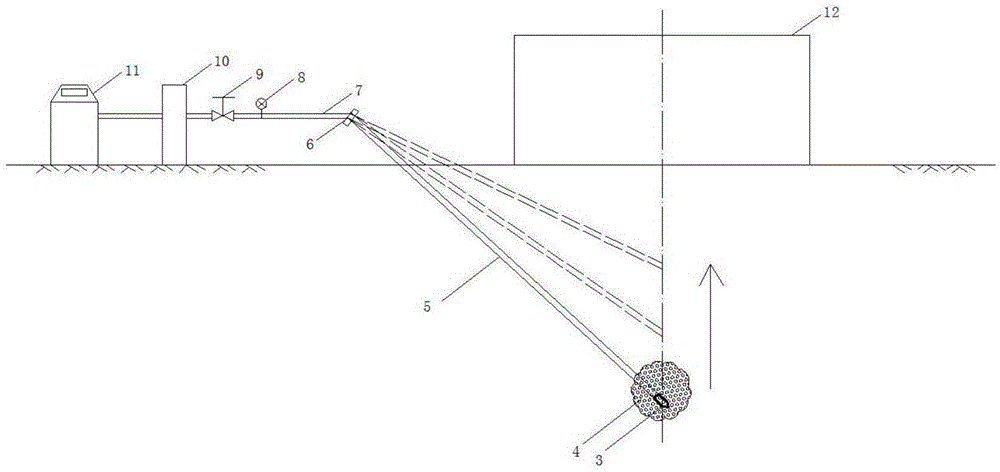

[0041]Embodiment 2: A kind of micro-nano bubble treatment can liquefy the ground and thereby strengthen the operation method of existing building foundation, such as figure 2 As shown, the difference with the embodiment is only that, step 3) when embedding the air jet head, utilize the drilling rig to drive the hollow drill rod 5 with the air jet head 3 obliquely into the bottom of the foundation liquefiable sand layer and remove the drilling machine, and ensure The jet head 3 is under the existing building, so that the top of the hollow drill pipe 5 is exposed to the ground. Step 5) During air injection, after the first air injection is completed, in order to vertically lift the air injection head 3 up by 3m to 4m, it is necessary to drill into the liquefiable sand from the recalculated borehole 2 through the hollow drill pipe 5 layer, and make the jet head 3 accurately located 3m-4m above the first jet. All the other construction steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com