Method for surface modification of ZnSe:Ag quantum dots

A technology of surface modification and quantum dots, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of surface defects, reduce the fluorescence efficiency of quantum dots, and high activity, and achieve the effect of less agglomeration, simple experimental operation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

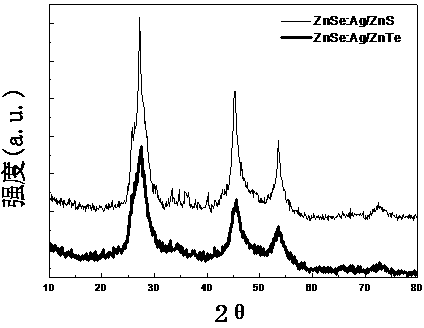

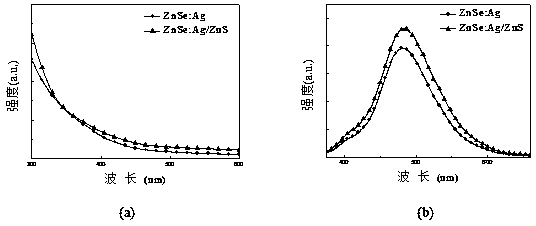

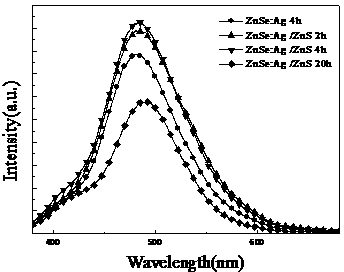

[0022] ZnSe: the preparation method of Ag / ZnS quantum dot,

[0023] Specific embodiments of the present invention will now be described below. The first step is to prepare ZnSe:Ag quantum dots. The process is to first prepare the Se source, that is, in a 100ml pear-shaped bottle, after passing through argon for about 30 minutes, add 0.8mmol NaBH in sequence 4 , 0.2mmol selenium powder (Se) and 2ml deionized water reacted for 30min; secondly prepare the Zn source, that is, in a 250ml three-necked flask, pre-pass argon for 30min, then add 0.8mmol zinc nitrate, 0.024mmol silver nitrate, 100ml deionized water and 200 μL 3-mercaptopropionic acid, adjust the pH value to 9 with 2M NaOH, place the three-necked flask in an oil bath at 100°C and heat for 1 h; finally inject the Se source solution into the Zn solution quickly with a syringe, and continue to pass through Argon and maintain 100 ° C oil bath, after 4 hours of reaction;

[0024] The second step is to add 0.2mmol...

Embodiment 2

[0029] ZnSe: the preparation method of Ag / ZnTe quantum dot,

[0030] The first step is to prepare ZnSe:Ag quantum dots. The process is to first prepare the Se source, that is, in a 100ml pear-shaped bottle, after passing through argon for about 30 minutes, add 0.8mmol NaBH in sequence 4 , 0.2mmol selenium powder (Se) and 2ml deionized water reacted for 30min; secondly prepare the Zn source, that is, in a 250ml three-necked flask, pre-pass argon for 30min, then add 0.8mmol zinc nitrate, 0.024mmol silver nitrate, 100ml deionized water and 200 μL 3-mercaptopropionic acid, adjust the pH value to 9 with 2M NaOH, place the three-necked flask in an oil bath at 100°C and heat for 1 h; finally inject the Se source solution into the Zn solution quickly with a syringe, and continue to pass through Argon and maintain 100 ° C oil bath, after 4 hours of reaction;

[0031] The second step is that in a 100mL pear-shaped flask, after passing through argon for about 30 minutes, add 0.8mmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com