Polymer material with two-way shape memory and preparation method thereof

A technology of polymer materials and memory polymers, which can be applied to household appliances, other household appliances, household components, etc., can solve the problems of high price, difficult preparation conditions, and high shape transition temperature, and achieve low cost, simple preparation technology, and easy Effects of operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

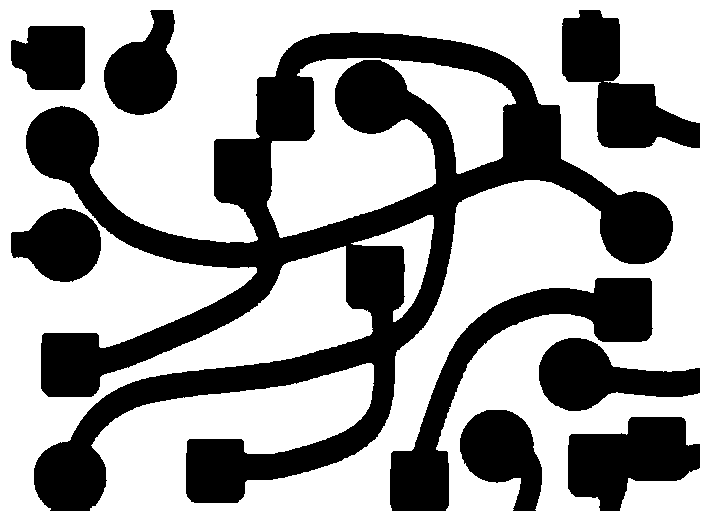

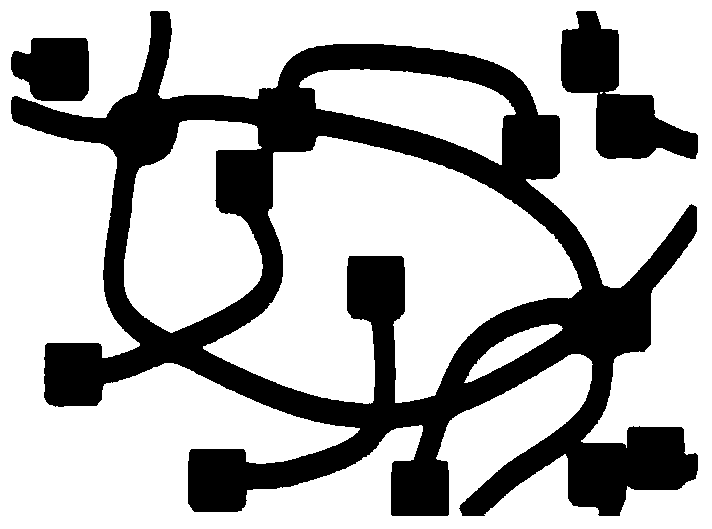

Image

Examples

preparation example Construction

[0027] The present invention further proposes a method for preparing the above-mentioned polymer material with two-way shape memory, comprising the following steps:

[0028] S10, obtaining polymer raw materials containing crystalline polymer chain forging;

[0029] S20, obtaining elastic material polymer raw materials;

[0030] S30, mixing polymers containing crystalline polymer chain forging and elastic material polymers to form a mixture, and performing the first stimulation treatment on the mixture in the first stimulation mode, so that the crystalline polymer in the mixture is exchanged Linked to obtain a cross-linked polymer;

[0031] S40, after elongating and fixing the primary cross-linked polymer, perform a second stimulation treatment with a second stimulation method to make the elastic material polymer form a cross-link, that is, obtain the two-way shape memory polymer material of the present invention.

[0032] Among them, in steps S30 and S40, the purpose is to m...

Embodiment 1

[0043] raw material:

[0044] Polycaprolactone, self-made in the laboratory; its main indicators are: the polymer is end-capped with carbon-carbon double bonds, and the melting temperature is 35-40°C;

[0045] Polytetrahydrofuran, self-made in the laboratory; its main indicators are: the polymer is epoxy-terminated, and the molecular weight ranges from 750 to 1250;

[0046] Benzoin dimethyl ether, preferably purchased from Aldrich-sigma company;

[0047] Polytetrahydrofuran diamine, self-made in the laboratory; its main index is 250 molecular weight.

[0048] making process:

[0049] S10, mixing and dissolving polycaprolactone, polytetrahydrofuran, benzoin dimethyl ether, and polytetrahydrofuran diamine in dimethylformamide according to the content requirements of the product to form a mixture, and pouring it into a rectangular mold;

[0050] S20, using an ultraviolet lamp to irradiate the mixture for 2 hours to obtain a gel product;

[0051] S30, the gel product is elonga...

Embodiment 2

[0054] raw material:

[0055] Shape memory polyurethane, self-made in the laboratory; its main indicators are: the hard segment is 4,4'-diphenylmethane diisocyanate / 1,4-butanediol, the soft segment is polycaprolactone, and the melting temperature of the hard segment is 180 ~200℃, the melting temperature of the soft segment is 35~40℃;

[0056] Polyurethane elastomer, self-made in the laboratory; its main indicators are: the hard segment is hexamethylene diisocyanate / 1,4-butanediol, the soft segment is polytetrahydrofuran, the melting temperature of the hard segment is 130-150°C, and the soft segment is glass The transformation temperature is -20~-50℃;

[0057] Preparation:

[0058] S10, the above two polyurethane raw materials are uniformly dissolved in dimethylformamide according to the amount required by the product, and poured into a mold to form a film at 80°C;

[0059] S20, elongate the film to double and fix it, and put it in a 140°C oven for 1 minute;

[0060] S30, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Transition temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com