Preparation method of hydrophobing agent

A hydrophobic agent and catalyst technology, which is applied in the field of preparation of hydrophobic agents, can solve the problems of film layer structure damage, not being widely used, hydrophobic function failure, etc., to increase reaction density, improve solubility, prevent polymerization and crystallization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

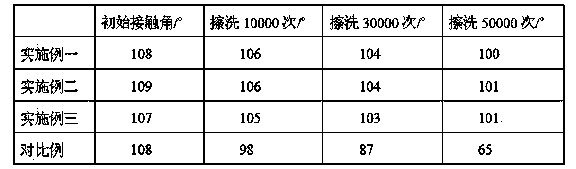

Examples

Embodiment 1

[0023] Add 3g of heptadecafluorodecyltriethoxysilane to 100g of ethanol, then add 2g of 37wt% hydrochloric acid and 1g of distilled water, and stir at room temperature for 120min. Next, 150 g of perfluorotributylamine was added into the system, vigorously stirred for 5 hours at room temperature, and the upper liquid was removed after standing to obtain a hydrophobic agent.

[0024] The hydrophobic agent is coated on the glass surface to form a film by scrape coating, and a hydrophobic film with good durability can be obtained after 24 hours of natural storage.

Embodiment 2

[0026] Add 3g of heptadecafluorodecyltriethoxysilane to 100g of ethyl acetate, then add 2g of acetic acid and 1g of distilled water, and stir at room temperature for 120min. Next, 150 g of perfluorooctane was added into the system, vigorously stirred at room temperature for 20 h, and the upper liquid was removed after standing to obtain a hydrophobic agent.

[0027] The hydrophobic agent is coated on the glass surface to form a film by scrape coating, and a hydrophobic film with good durability can be obtained after 24 hours of natural storage.

Embodiment 3

[0029] Add 3g of heptadecafluorodecyltriethoxysilane to 100g of isopropanol, then add 2g of acetic acid and 1g of distilled water, and stir at room temperature for 120min.

[0030] Next, 150 g of perfluorobutyltetrahydrofuran was added into the system, vigorously stirred at room temperature for 20 h, and the supernatant liquid was removed after standing to obtain a hydrophobic agent.

[0031] The hydrophobic agent is coated on the cleaned glass surface to form a film by scrape coating process, and the hydrophobic film layer with good durability can be obtained after being placed naturally for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com