Automatic high-speed metal tube cutting machine

A technology for metal pipes and cutting machines, which is applied in the direction of metal processing equipment, pipe shearing devices, and accessories of shearing machines, etc. It can solve the problems affecting the surface smoothness and shearing accuracy of the cut workpiece, rough cutting surface, and high cutting force, etc. problems, to achieve the effect of high man-machine work efficiency, easy operation and maintenance, and high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

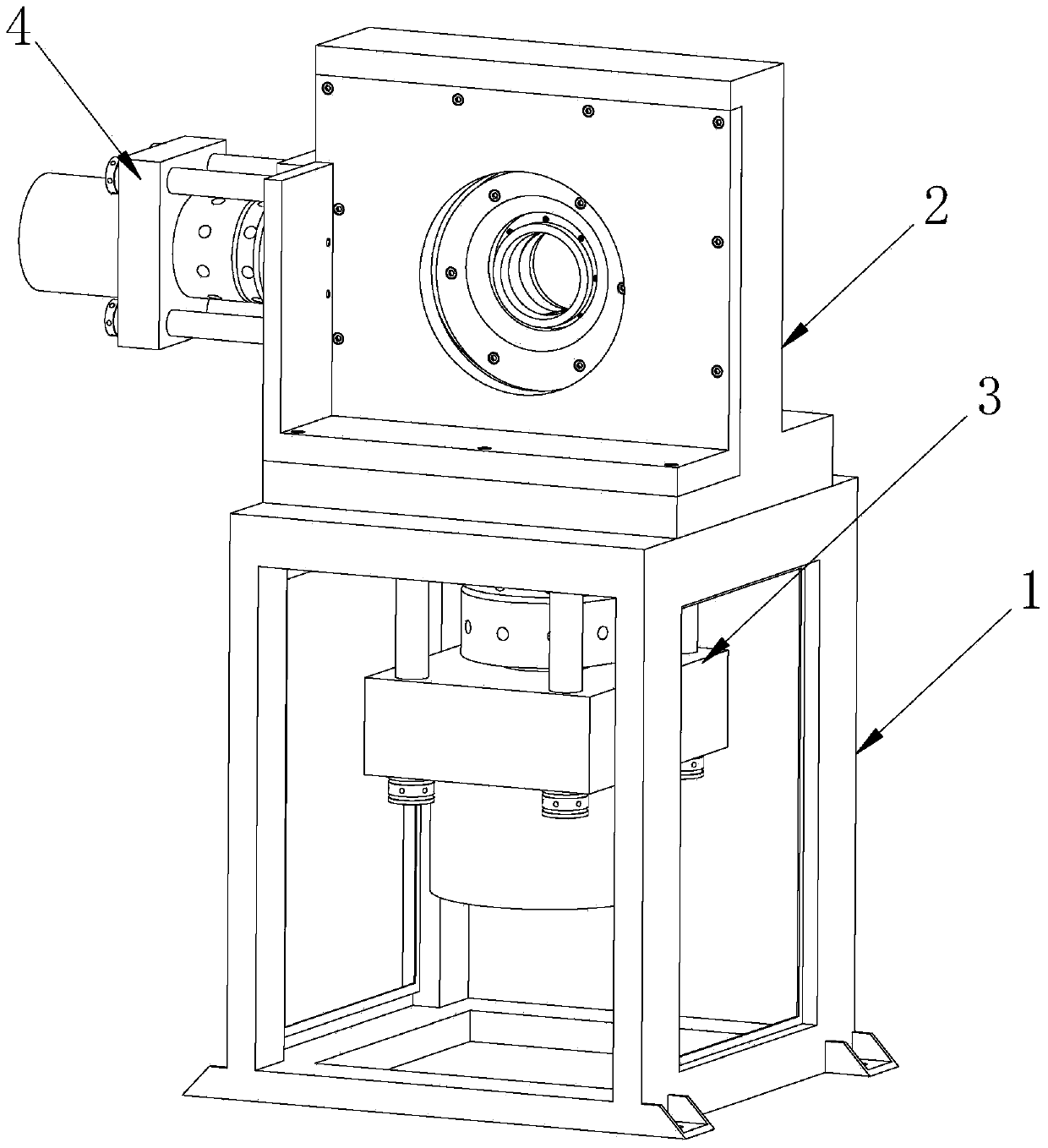

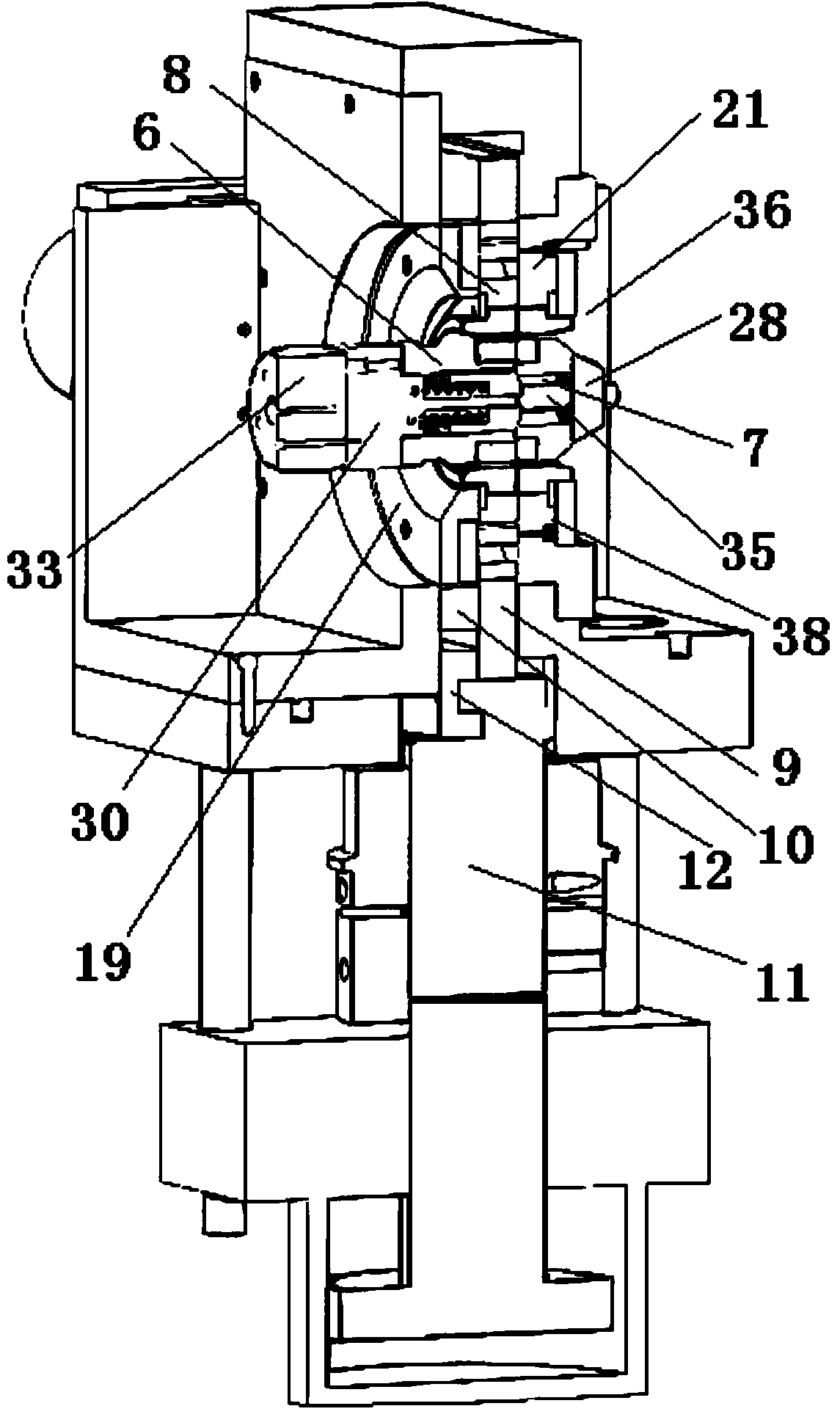

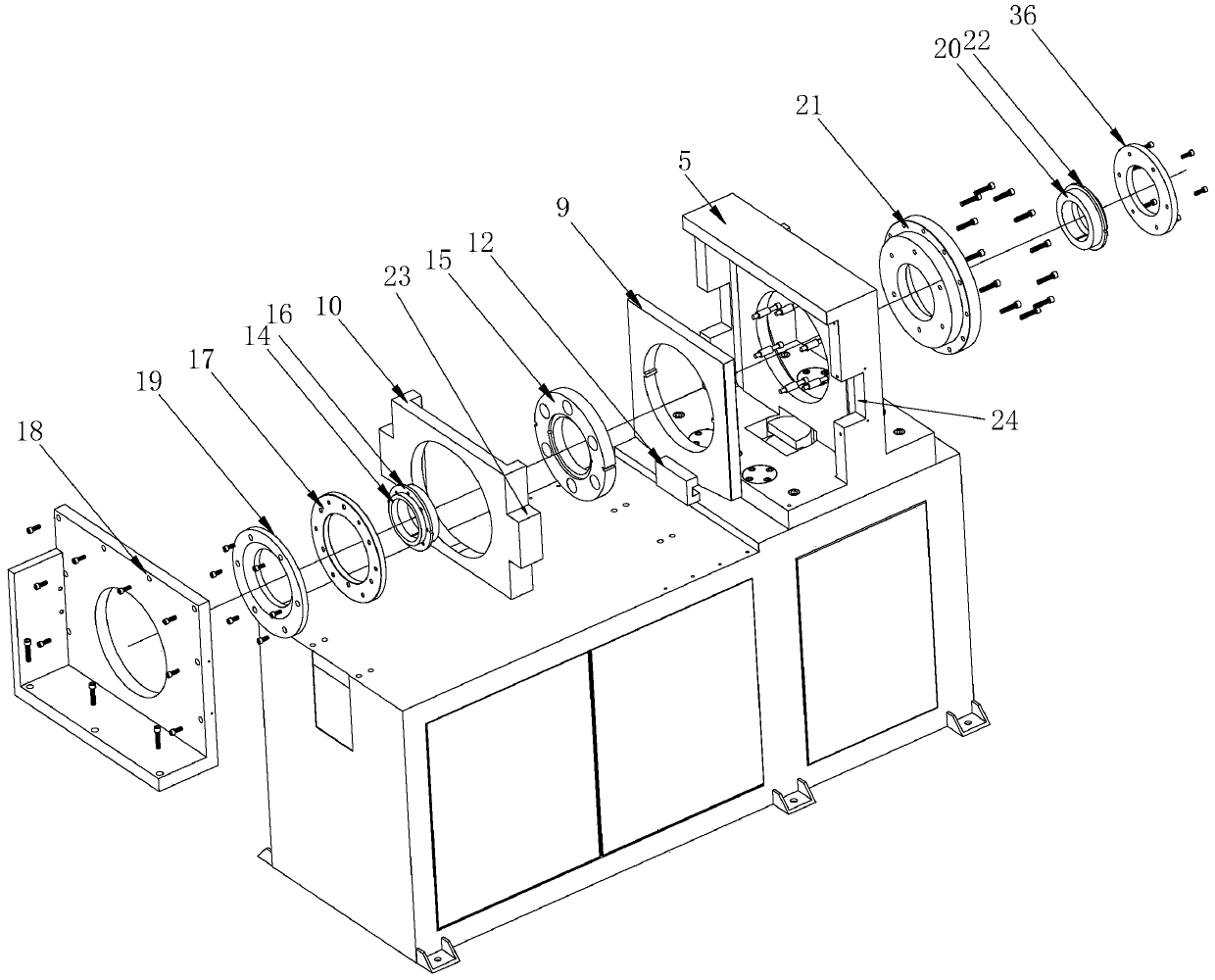

[0024] Such as Figure 1-5 As shown, an automatic high-speed metal pipe cutting machine according to an embodiment of the present invention includes a frame assembly 1 and a shearing machine assembly 2. The bottom of the shearing machine assembly 2 is provided with a lower hydraulic cylinder assembly 3. The side of the shear assembly 2 is provided with a side hydraulic cylinder assembly 4. The shear assembly 2 includes a main base 5, and the main base 5 is provided with an inner floating knife assembly 6, an inner fixed knife assembly 7, and an outer floating knife The assembly 8 and the outer fixed knife assembly 38, the inner floating knife assembly 6 is concentric with the outer floating knife assembly 8, the inner fixed knife assembly 7 is concentric with the outer fixed knife assembly 38, the inner floating knife assembly 6 and the inner fixed knife assembly 7 An inner knife assembly is formed. The outer floating knife assembly 8 and the outer fixed knife assembly 38 const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com