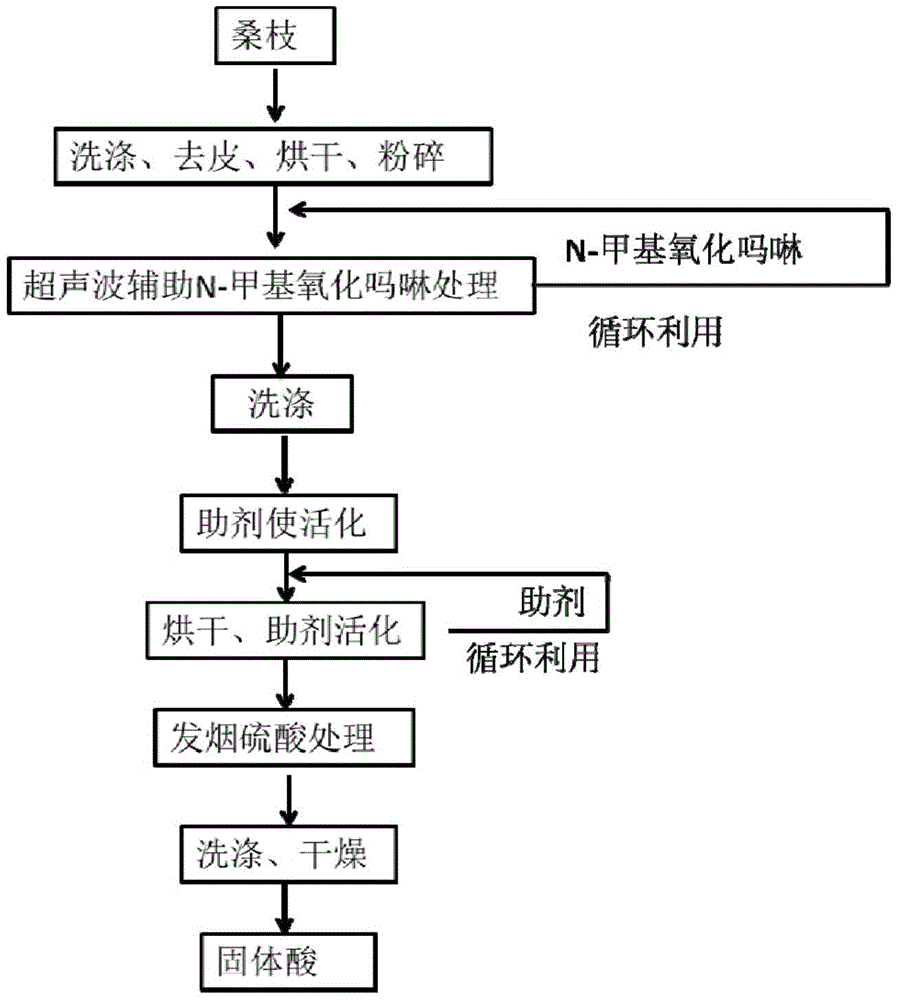

A kind of preparation method of mulberry base solid acid

A solid acid, mulberry-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low adsorption performance and catalytic performance, large particle size of carbon-based solid acid, etc. , to achieve the effect of abundant raw materials, high preparation rate and solving the shortage of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Get the mulberry branch and cut off the mulberry branch skin with a knife, cut off the mulberry branch skin, wash away the sediment with tap water, dry at 105°C for 2 hours, pulverize, and pass through a 10-mesh sieve;

[0028] (2) Get 100g mulberry powder, add 1000g20% N-methylmorpholine oxide, process 3h at 80°C, add 1L water to the system to precipitate the mulberry powder, wash with water 2-3 times, Remove N-methylmorpholine oxide (the aqueous solution of N-methylmorpholine oxide can be distilled to remove water to a certain concentration for reuse);

[0029] (3) Add 5g of zinc chloride, stir evenly, filter to remove water, and dry at 105°C;

[0030] (4) The product obtained in step (3) is put into a crucible, placed in a tube furnace, protected by nitrogen, and heat-treated at 500° C. for 3 hours;

[0031] (5) Get the product obtained in step (4), add 100 g of oleum of 20% sulfur trioxide, heat and stir at 80° C. for acidification treatment for 2 h, remove aci...

Embodiment 2

[0033] (1) Get the mulberry branch and cut off the mulberry branch skin with a knife, cut off the mulberry branch skin, wash away the sediment with tap water, dry at 105°C for 2 hours, pulverize, and pass through a 10-mesh sieve;

[0034] (2) Take 100g of mulberry powder, add 800g of 60% N-methylmorpholine oxide, treat it at 100°C for 0.5h, add 1L of water to the system to precipitate the mulberry powder, wash with water 2-3 times , remove N-methylmorpholine oxide (the aqueous solution of N-methylmorpholine oxide can be distilled to remove water to a certain concentration for reuse);

[0035] (3) Add 6g ferric chloride, stir evenly, filter to remove water, and dry at 105°C;

[0036] (4) The product obtained in step (3) is put into a crucible, placed in a tube furnace, protected by nitrogen, and heat-treated at 400° C. for 5 hours;

[0037] (5) Get the product obtained in step (4), add 300 g of oleum of 20% sulfur trioxide, heat and stir at 80° C. for acidification treatment f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com