Fluidized bed reactor and method for preparing granular polysilicon and trichlorosilane by employing same

A fluidized bed reactor, trichlorosilane technology, applied in chemical instruments and methods, halogenated silicon compounds, silicon, etc., can solve the problems of affecting the production capacity of the reactor, reducing the heating efficiency, affecting the operating cycle of the reactor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it must be noted that the protection scope of the present invention is not limited by these specific embodiments, and the specific materials and reactor structures involved in the specific embodiments and The connection mode is listed in this specific embodiment to illustrate the present invention, but not to limit the present invention. The protection scope of the present invention is determined by the claims.

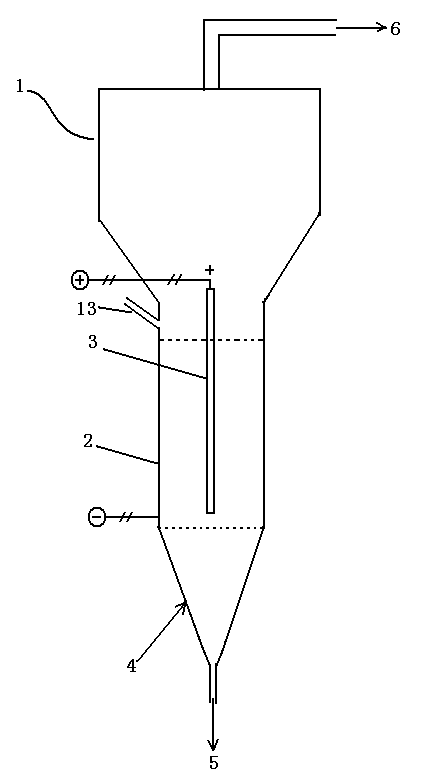

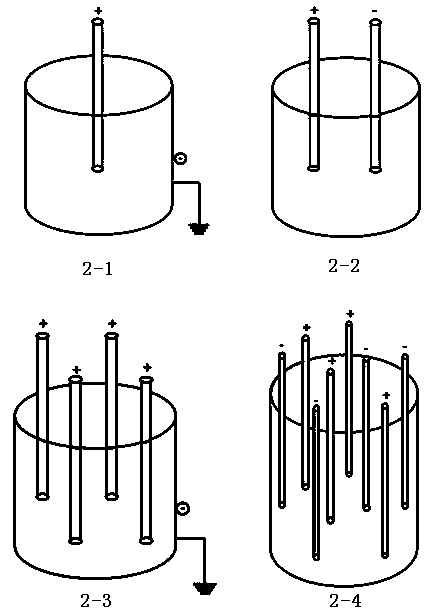

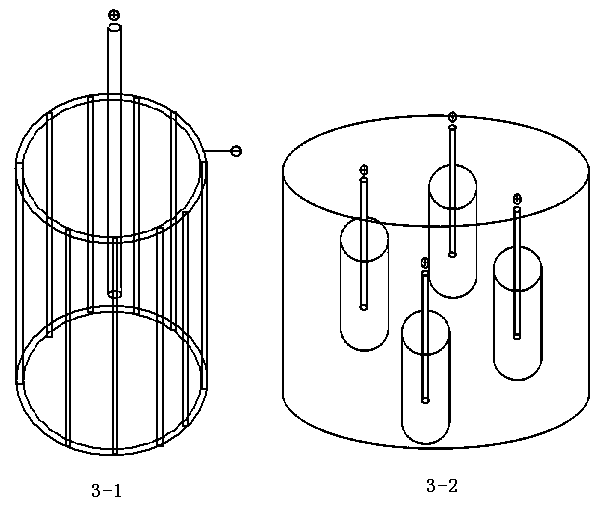

[0044] Such as figure 1 As shown, the internal space of the fluidized bed reactor 1 is defined by the shell 2, which includes three parts: the lower cone from bottom to top, the reaction zone and the expansion section. The top of the shell 2 is provided with a reaction tail gas outlet. 6. The upper part of the housing 2, more specifically the upper part of the reaction zone is provided with a seed crystal feed port 13, and the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com