Rock drilling simulation test device and method for determining pressure and torque of test pole

A technology for drilling into rock simulation and test equipment, which is applied in the direction of soil material testing and material inspection products, and can solve problems such as backward test methods, rough classification, and gaps between theory and practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

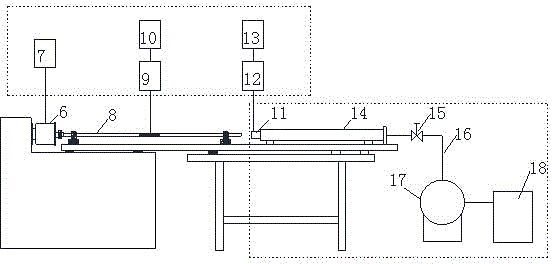

[0051] Below in conjunction with accompanying drawing and specific embodiment of the present invention will be described in further detail:

[0052] 1. The specifications of the instrument used in the test

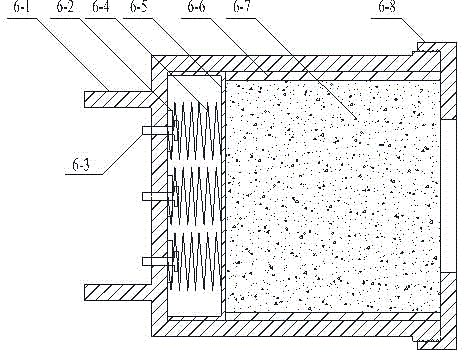

[0053] The test piece cabin 6 of the test device is composed of a canopy, a spring seat, a screw, a spring, a support plate, a steel hoop, a rock specimen and a hatch cover. The outer diameter of the canopy is 150mm, the wall thickness is 20mm, and the outer diameter of the steel hoop is 110mm, the wall thickness is 5mm, three springs are set on the spring seat, and the spring diameter is 50mm. Hatch cover, the hatch cover and the hatch cover are connected with threads.

[0054] The launch rod has a diameter of 40mm and a length of 500m, and the test rod has a diameter of 40mm and a length of 500mm, all of which are made of nickel-chromium steel. E 0 2.06×10 5 MPa, shear modulus G 0 is 7.938×10 4 MPa, density ρ 0 7.1×10 3 kg / m 3 . The launch tube has an outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com