Water stop structure for water inlet device of toilet bowl

A technology for water inlet devices and water tanks, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of increased lateral dimensions, increased unstable factors, time-consuming and troublesome problems, and achieves reduced wear and tear, convenient installation and Debugging and ensuring the effect of pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

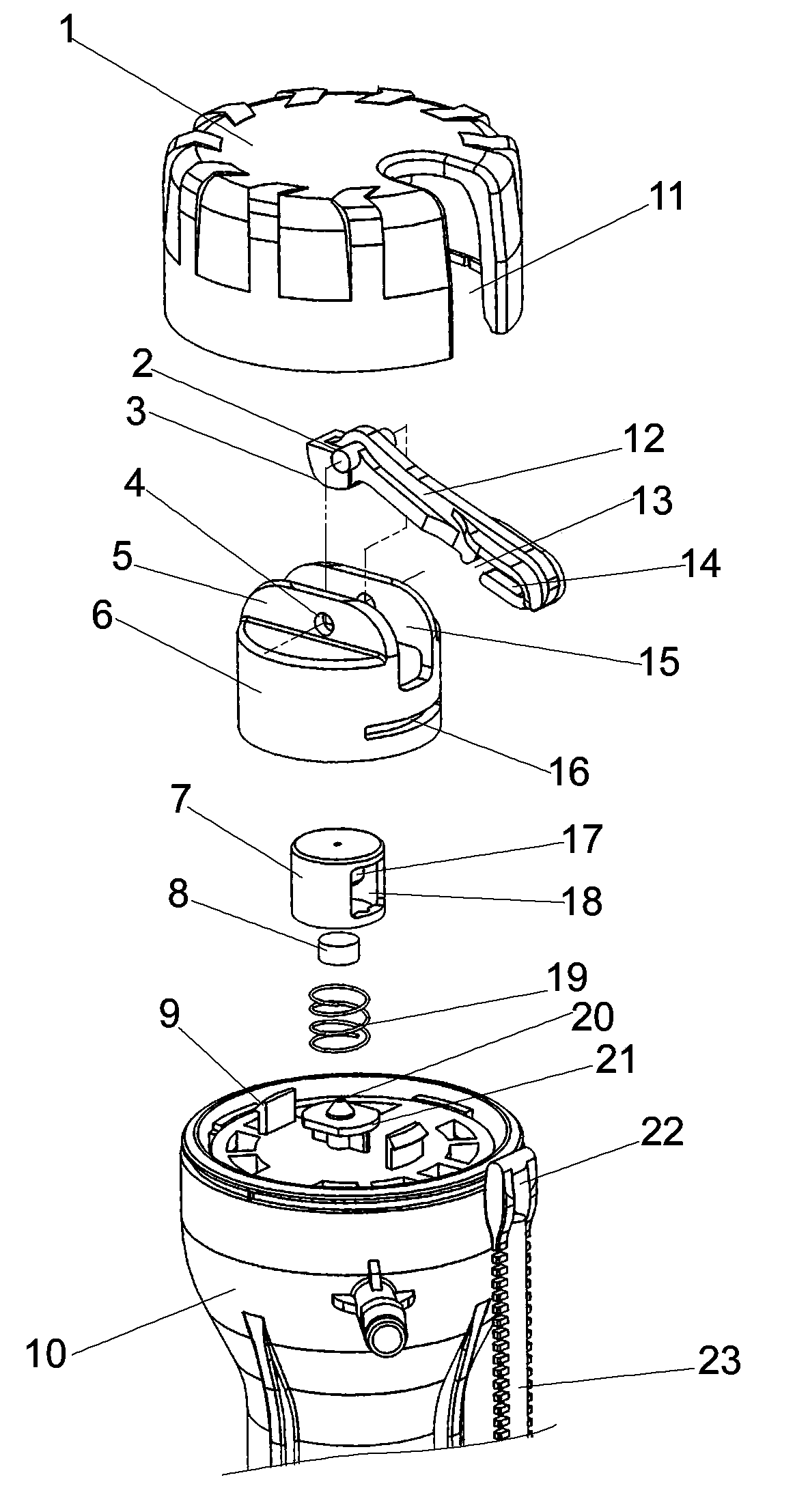

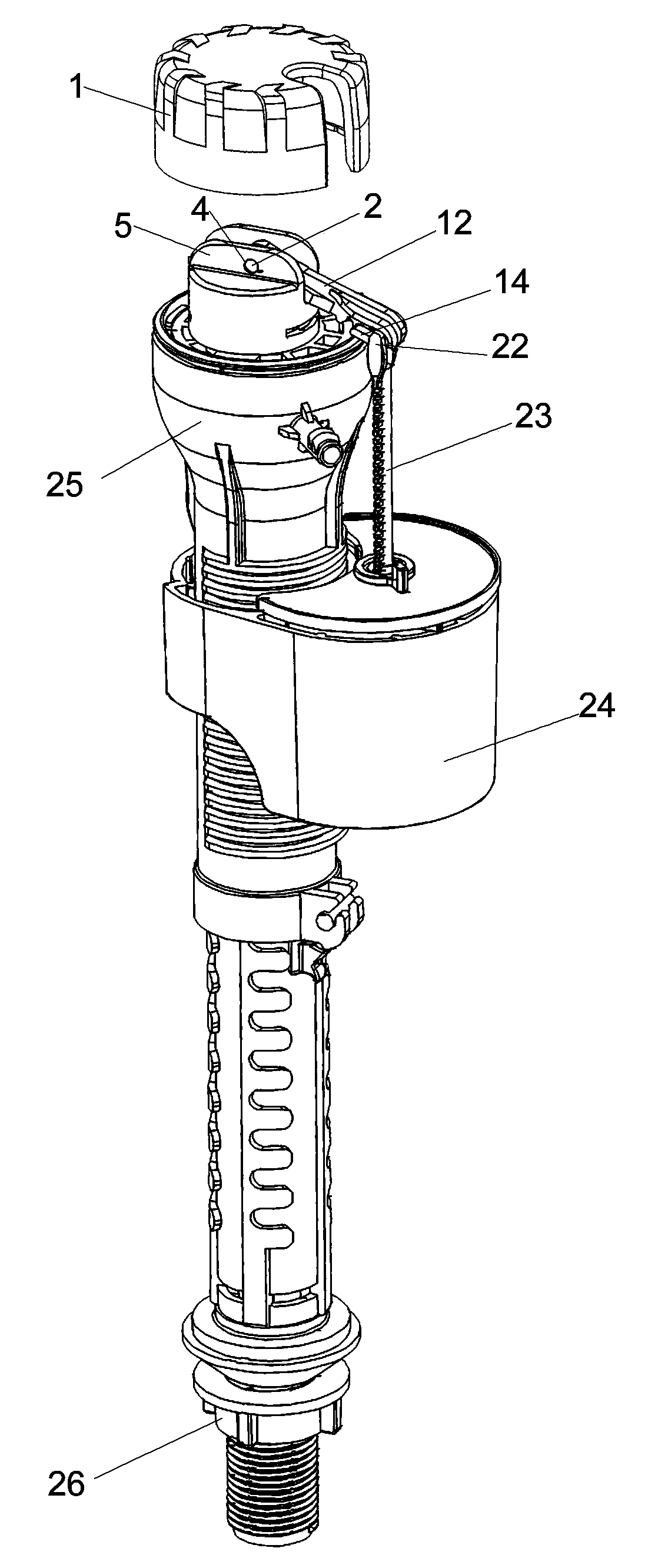

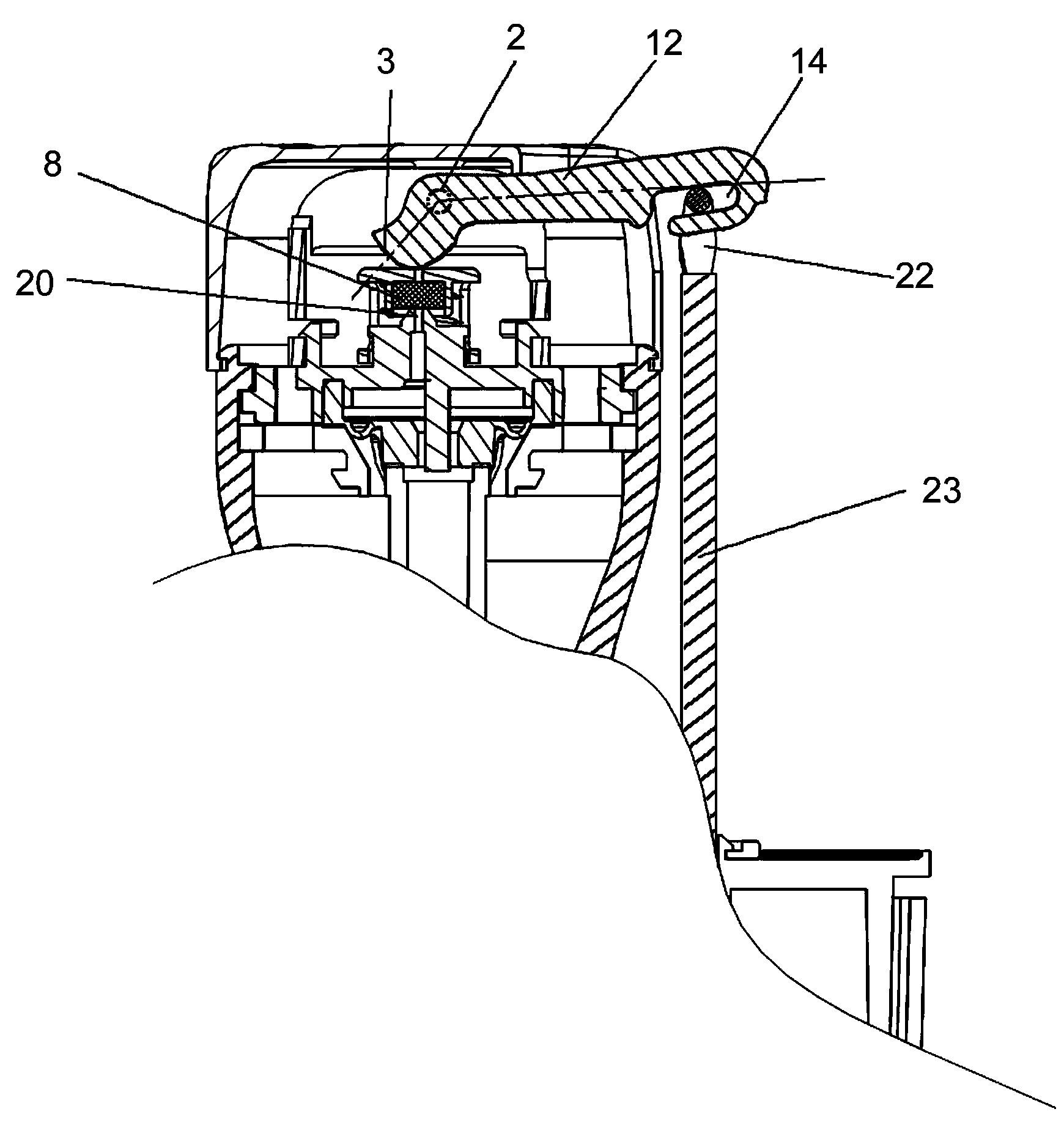

[0021] As shown in the figure, the present invention is a water stop structure suitable for the water inlet device of the toilet tank, including a water inlet valve 10, the bottom of which can be fixed in the toilet water tank through a nut 25, and a ventilator is provided at the center of the top surface of the water inlet valve 10. Seat platform, air vent 20 is provided on the table top of ventilation seat, and convex edge 21 is provided on both sides of ventilation seat platform. Press the round cover 7, the top of the press round cover 7 is provided with a circular groove 17, a sealing gasket 8 is filled in the circular groove 17, a spring 19 is connected outside the circular groove 7, and the two sides of the pressed circular cover 7 are hollowed out as guides. Window 18, press the round cover 7 through the lower window frame and the convex edge 21 of the ventilation seat platform, and the lower window frame is limited to move in the limit structure formed between the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com