Tantalum nitride nanotube array electrode and preparation method thereof

A nanotube array and tantalum nitride technology, which is applied in the field of photoelectrochemistry, can solve the problems of small surface area, limitation, and obstruction of electron transport, and achieve the effects of good repeatability, overcoming discontinuous irradiation, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

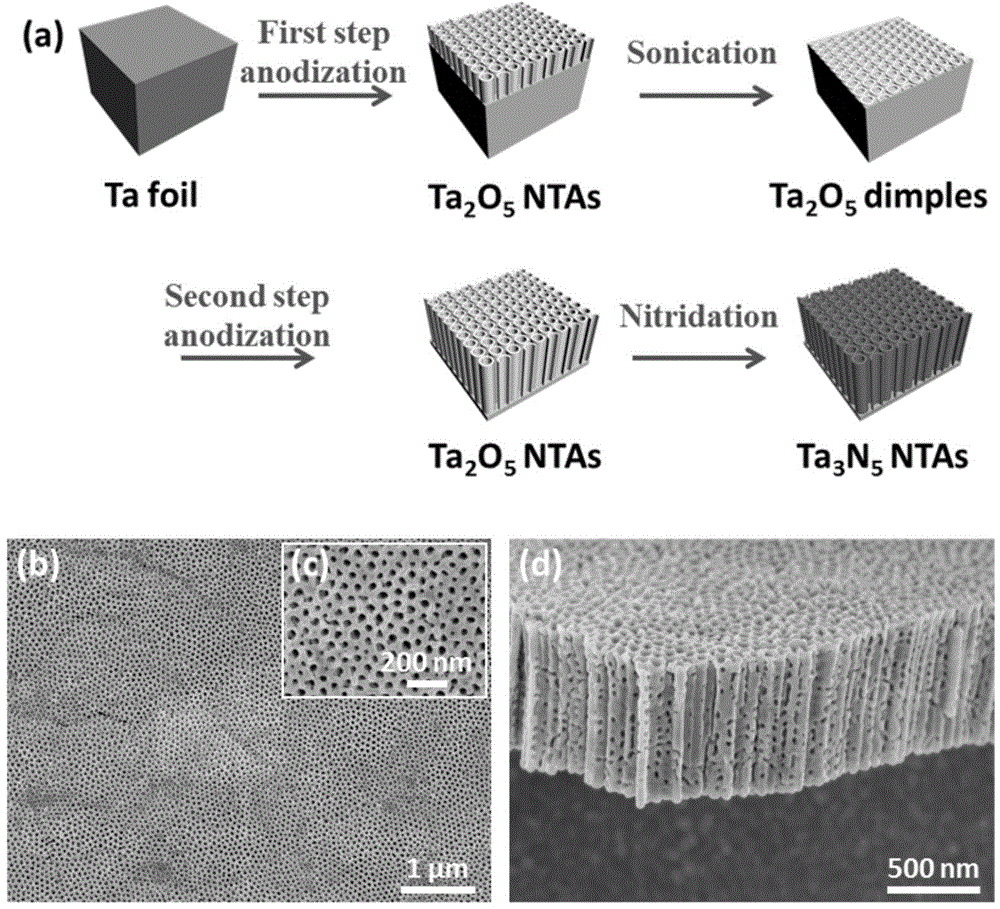

Embodiment 1

[0037] (1) Preparation of Ta substrate

[0038] Cut a metal Ta sheet with a thickness of 0.25mm and a purity of 99.5% into 1×2cm 2 Small pieces of, respectively, ultrasonic treatment in acetone, deionized water, ethanol solution for 30 minutes; clean the surface with deionized water; dry;

[0039] (2) Preparation of electrolyte

[0040] Take 27ml H 2 SO 4 , 2.5ml deionized water, 0.5ml HF aqueous solution, prepared into a concentration of 0.383mol / L HF H 2 SO 4 The solution is ready for use. Take 27ml H 2 SO 4 , 2.7ml deionized water, 0.3ml HF aqueous solution, prepared into a concentration of 0.230mol / L HF H 2 SO 4 The solution is ready for use.

[0041] (3) Primary anodic oxidation

[0042] In a standard two-electrode electrochemical cell, the H of HF with a concentration of 0.383mol / L 2 SO 4 The solution is an electrolyte solution, measuring 1×2cm 2 Ta sheet is anode, 2×2cm 2 The platinum electrode is the cathode, the distance between the two electrodes is 1cm, the DC voltage of the...

Embodiment 2

[0052] (1) The preparation of Ta substrate is the same as in Example 1.

[0053] (2) The preparation of the electrolyte is the same as in Example 1.

[0054] (3) The conditions and process of primary anodization are the same as in Example 1.

[0055] (4) Secondary anodic oxidation

[0056] In a standard two-electrode electrochemical cell, the H of HF with a concentration of 0.230mol / L 2 SO 4 The solution is an electrolyte solution, and the ultrasonic Ta substrate is used as the anode, 2×2cm 2 The platinum electrode is the cathode, the distance between the two electrodes is 1cm, the DC voltage of the potentiostat is 5V, the oxidation temperature is 0°C, and the oxidation time is 5min. Perform anodization; carefully rinse off the electrolyte solution on the surface with deionized water;

[0057] (5) The nitriding treatment conditions and process are the same as in Example 1.

[0058] The experimental results show that the inner diameter of the nanotubes of the tantalum nitride nanotube arr...

Embodiment 3

[0061] (1) The preparation of Ta substrate is the same as in Example 1.

[0062] (2) The preparation of the electrolyte is the same as in Example 1.

[0063] (3) The conditions and process of primary anodization are the same as in Example 1.

[0064] (4) Secondary anodic oxidation

[0065] In a standard two-electrode electrochemical cell, the H of HF with a concentration of 0.230mol / L 2 SO 4 The solution is an electrolyte solution, and the ultrasonic Ta substrate is used as the anode, 2×2cm 2 The platinum electrode is the cathode, the distance between the two electrodes is 1cm, the DC voltage of the potentiostat is 35V, the oxidation temperature is 0°C, and the oxidation time is 5min, for anodic oxidation; carefully rinse off the electrolyte solution on the surface with deionized water;

[0066] (5) The nitriding treatment conditions and process are the same as in Example 1.

[0067] Experimental results show that the inner diameter of the nanotubes of the tantalum nitride nanotube array...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com