Antimicrobial biodegradable packaging hose material and method for preparing hose using same

A technology of biodegradation and biodegradable resin, which is applied in packaging hose materials, antibacterial biodegradable packaging hose materials and their manufacturing fields, to achieve the effects of reducing the cost of use, alleviating environmental protection, and reducing the pressure of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

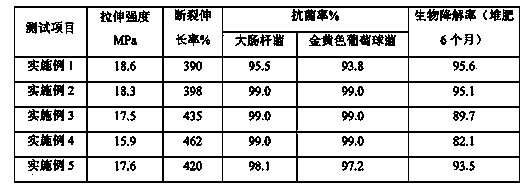

Examples

preparation example Construction

[0036] The preparation method of the antibacterial biodegradable packaging hose of the present invention includes the preparation method of the antibacterial masterbatch and the preparation method of the hose.

[0037] The steps of the preparation method of the antibacterial masterbatch include: the antibacterial agent is treated with a double-layer coating on the surface of a fluidized bed, and the first layer of coating treatment uses a silane coupling agent, a titanate or an aluminate coupling agent as a surface treatment agent, After the first layer of treatment is completed, it is dried on the spot, and then the second layer is coated with polybutylene succinate PBS, polybutylene adipate terephthalate PBAT or polyvinyl alcohol PVA solution. After being coated, it is dried to obtain a double-coated antibacterial agent.

[0038] The steps of the hose preparation method include: preliminarily mixing biodegradable resin, antibacterial masterbatch, antioxidant, plasticizer and...

Embodiment 1

[0041] The raw material components and mass percentage ratio of the antibacterial biodegradable packaging hose material are:

[0042] PBAT biodegradable resin: 95%,

[0043] Antibacterial masterbatch: 3%,

[0044] Antioxidant: 0.5%,

[0045] Plasticizer: 1%,

[0046] Stearic acid: 0.5%.

[0047] Weigh the raw materials according to the above mass percentage distribution ratio, and mix them uniformly in the mixer to obtain the mixed material, and then extrude the mixed material through the extruder to obtain a hose with a diameter of 10-50 mm and a wall thickness of 0.3-1 mm. After forming, it is cooled and cut into segments. Injection molding is performed on the segmented tubes, followed by printing and sealing processes.

Embodiment 2

[0049] The raw material components and mass percentage ratio of the antibacterial biodegradable packaging hose material are:

[0050] PBAT biodegradable resin: 91%,

[0051] Antibacterial masterbatch: 5%,

[0052] Antioxidant: 0.5%,

[0053] Plasticizer: 3%,

[0054] Oleamide: 0.5%.

[0055] Weigh the raw materials according to the above-mentioned parts by mass, and mix them uniformly in the mixer to obtain the mixed material, and then extrude the mixed material through an extruder to obtain a hose with a diameter of 10-50 mm and a wall thickness of 0.3-1 mm. After cooling, knife cutting and segmentation. Injection molding is performed on the segmented tubes, followed by printing and sealing processes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com