Preparation method of high-cis-content butadiene-isoprene copolymer

A technology of isoprene and butadiene is applied in the field of preparation of butadiene-isoprene copolymers with high cis content, and can solve the problems of wide molecular weight distribution and low cis content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

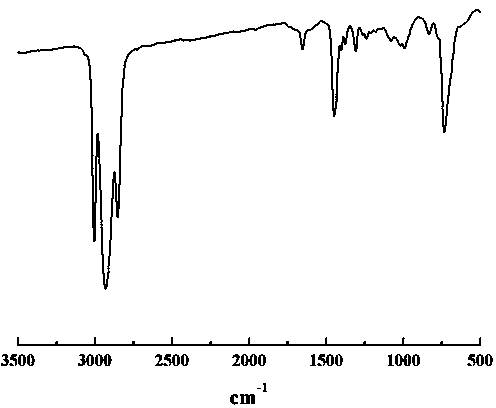

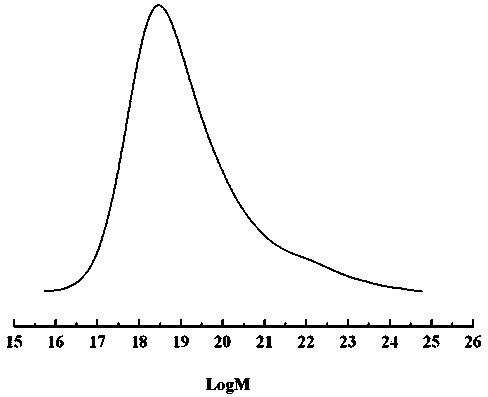

Image

Examples

Embodiment 1

[0029] Under nitrogen protection, add diisobutylaluminum hydride (HAl), isoprene (IP) and tris(2-ethylhexylphosphonic acid 2-ethylhexyl ester) neodymium in sequence to the dry catalyst reaction flask (Nd), after reacting at 30°C for 15 minutes, add diisobutyl aluminum chloride (Cl), and react at 60°C for 40 minutes to obtain a catalyst for the polymerization of butadiene and isoprene . In this catalyst, the molar ratio of [Nd] / [IP] / [HAl] / [Cl] is 1 / 30 / 5 / 2.5.

[0030] Under nitrogen protection, add 40 mL of the hexane solution of the reaction monomers butadiene and isoprene to a dry 100 mL ampoule, the molar ratio of butadiene to isoprene is 4:1, and then add the above-mentioned preparation Good catalyst, the mol ratio of reaction monomer and catalyst is 4000: 1;

[0031] The polymerization reaction was carried out at 30°C, and the polymerization reaction was terminated with ethanol solution after 4 hours, and coagulated with ethanol to obtain a random copolymer of butadiene a...

Embodiment 2

[0033] Under nitrogen protection, add diisobutylaluminum hydride (HAl), isoprene (IP) and tris(2-ethylhexylphosphonic acid 2-ethylhexyl ester) neodymium in sequence to the dry catalyst reaction flask (Nd), after reacting at 30°C for 10 minutes, add diisobutylaluminum chloride (Cl), and react at 60°C for 40 minutes to obtain a catalyst for the polymerization of butadiene and isoprene . In this catalyst, the molar ratio of [Nd] / [IP] / [HAl] / [Cl] is 1 / 30 / 5 / 2.5.

[0034] Under the protection of nitrogen, add 40 mL of the hexane solution of the reaction monomers butadiene and isoprene to a dry 100 mL ampoule, the molar ratio of butadiene and isoprene is 4:1, at -10 ° Freeze 1 hour under ℃, then add above-mentioned prepared catalyzer, the mol ratio of reaction monomer and catalyzer is 3000: 1;

[0035] The polymerization reaction was carried out at -10°C. After 48 hours, the polymerization reaction was terminated with ethanol solution, and the random copolymer of butadiene and isopr...

Embodiment 3

[0037] Under the protection of nitrogen, in the dry catalyst reaction bottle, add triisobutylaluminum (Al), isoprene (IP) and tris (2-ethylhexyl phosphonic acid 2-ethylhexyl ester) neodymium ( Nd), reacted at 30°C for 15 minutes, then added diisobutylaluminum chloride (Cl), and reacted at 60°C for 40 minutes to obtain a catalyst for the polymerization of butadiene and isoprene. In this catalyst, the molar ratio of [Nd] / [IP] / [Al] / [Cl] is 1 / 30 / 5 / 2.5.

[0038] Under the protection of nitrogen, add 40 mL of the hexane solution of the reaction monomers butadiene and isoprene to a dry 100 mL ampoule, the molar ratio of butadiene and isoprene is 4:1, at -10 ° Freeze 1 hour under ℃, then add above-mentioned prepared catalyzer, the mol ratio of reaction monomer and catalyzer is 3000: 1;

[0039]The polymerization reaction was carried out at -10°C. After 48 hours, the polymerization reaction was terminated with ethanol solution, and the random copolymer of butadiene and isoprene with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com