Method for producing methanol with coke oven gas

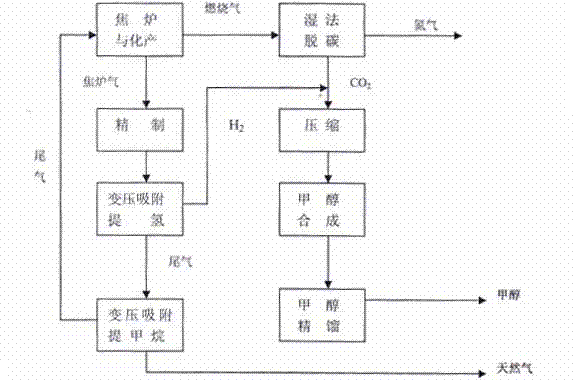

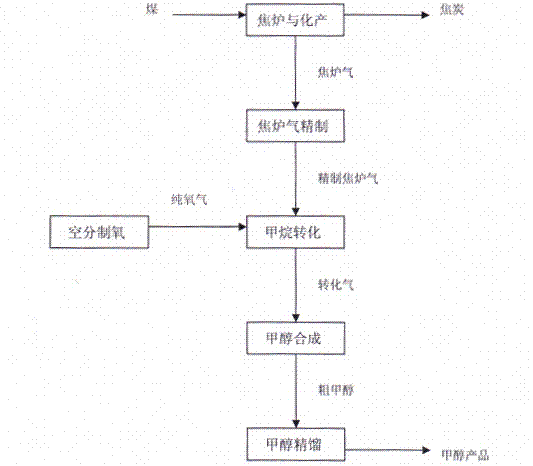

A technology for coke oven gas and methanol production, which is applied to chemical instruments and methods, gas fuels, and preparation of hydroxyl compounds. It can solve the problems of large water vapor consumption, pure oxygen, low calorific value of fuel, and huge energy consumption, and achieve economical Benefit improvement, investment reduction, good operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

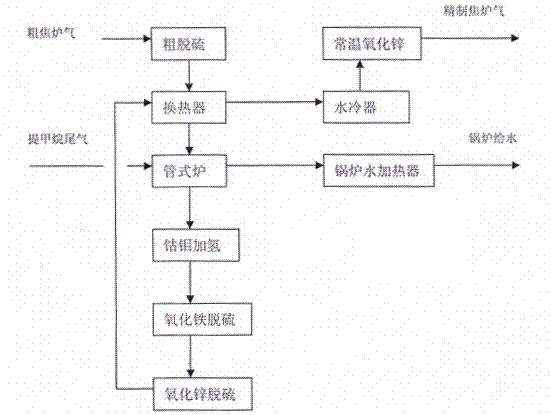

Method used

Image

Examples

Embodiment 1

[0027] Take coke oven gas produced by coke ovens with an annual output of 2 million tons as an example:

[0028] The coke oven gas produced by the coke oven and initially purified by chemical production is 103,400 cubic meters per hour, and the composition is: H 2 58%; CO 6.2%; CO 2 2.2%; CH 4 26%; CnHm2.5%; N 2 4.5%; H 2 S 50mg / Nm 3 ; Organic sulfur 400 mg / Nm 3 ;Calorific value 4288 kcal / Nm 3 (Different coking plants have slightly different changes in coke oven gas composition due to different coal blending), go to the compressor to increase the pressure to 0.8-2.5MPa(g) and send it to the refining device for refining (after refining, H 2 The content of S and total sulfur is less than 0.1PPm, other impurities are 0), the refined high-purity coke oven gas enters the pressure swing adsorption hydrogen extraction device, and 99.99% purity of hydrogen can be extracted according to the extraction rate of 90% 50000Nm 3 / h, for the synthesis of methanol. Tail gas after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com