Membrane biological treatment device and method for cooperative treatment of methane and sulfur and nitrogen-containing wastewater

A technology of synergistic treatment and membrane biology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, separation methods, etc., can solve the problem that methane-containing waste gas and sulfur-containing and nitrogen-containing waste water cannot be co-biologically treated, etc. To achieve the effect of compact structure, easy operation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

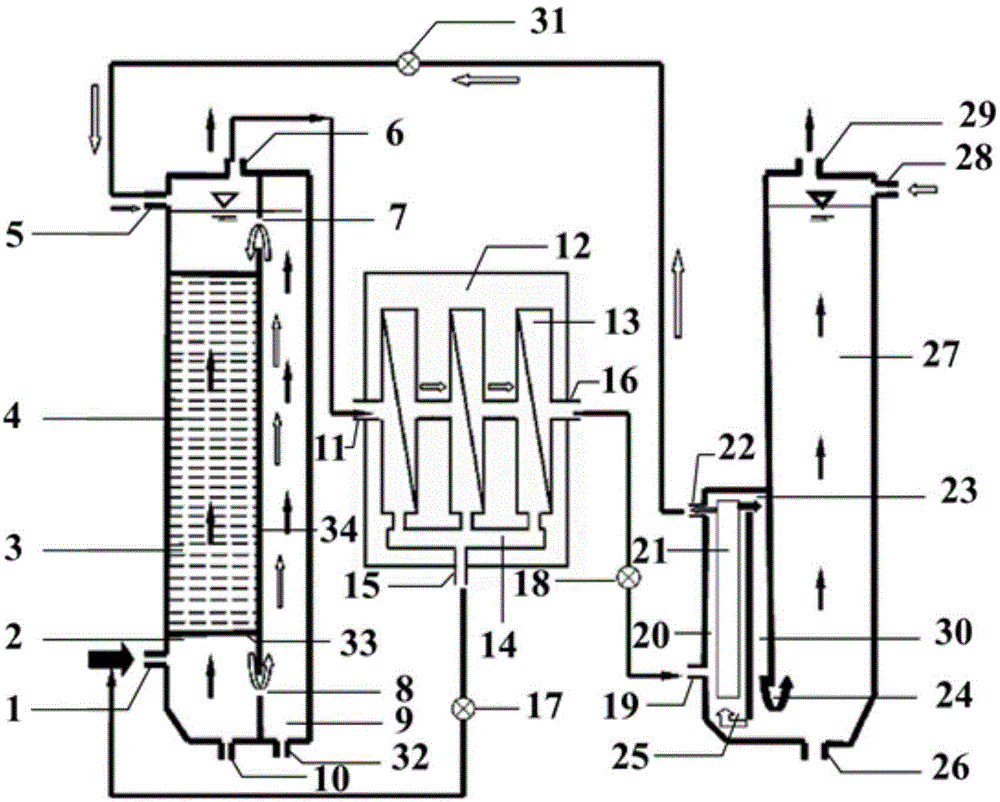

[0039] See figure 1 . Membrane biological treatment equipment for the combined treatment of methane-containing waste gas and sulfur-containing and nitrogen-containing wastewater made of plastic plates. The length, width and height are 1.5m, 0.5m and 1.2m respectively; Filler 3 attached to sulfate-reducing bacteria, circulation oxidation vessel 4 for accommodating methane oxidizing bacteria and sulfate-reducing bacteria suspension solution, gas membrane selective separation vessel 12, upflow regeneration for accommodating Thiobacillus denitrification suspension solution Container 27, solid-liquid separation container 20 and gas diversion container 30.

[0040] The interior of the circulating oxidation vessel 4 is equipped with a partition 34 to divide the circulating oxidation vessel into a fixed reaction zone 2 and a suspension reaction zone 9, and the fixed reaction zone 2 and the suspension reaction zone 9 are arranged on the partition 34 The first liquid diversion port 7 ...

Embodiment 2

[0051] See figure 1 . The combined membrane biological treatment equipment for the co-treatment of methane-containing waste gas and sulfur-containing and nitrogen-containing wastewater has a length, width and height of 4.0m, 2.50m and 1.50m respectively. The equipment structure and the treatment method for waste gas and waste water are the same as in Example 1.

[0052] Under room temperature conditions, the above-mentioned equipment is used to co-process methane-containing waste gas and sulfur- and nitrogen-containing waste water. Filler 3 is housed in the stationary reaction zone 2 of circulation oxidation vessel 4, and filler 3 is bark, and methane oxidizing bacteria and sulfate-reducing bacteria are attached on filler 3, in the suspended reaction zone 9 of circulation oxidation vessel 4 Methane-oxidizing bacteria and sulfate-reducing bacteria were suspended in the solution, and the content of methanotrophic bacteria was 1.0×10 6 CFU / ml, the content of sulfate-reducing b...

Embodiment 3

[0055] See figure 1 . The combined membrane biological treatment equipment for the co-treatment of methane-containing waste gas and sulfur-containing and nitrogen-containing wastewater has a length, width and height of 4.5m, 3.5m and 1.8m respectively. The equipment structure and the waste gas treatment method are the same as in Example 1.

[0056] Under room temperature conditions, the above-mentioned equipment is used to co-process methane-containing waste gas and sulfur- and nitrogen-containing waste water. Filler 3 is housed in the fixed reaction zone 2 of circulation oxidation vessel 4, and filler 3 is the mixture of resin foam and plastic ball, and methane oxidizing bacteria and sulfate reducing bacteria are attached on filler 3, and the suspension in circulation oxidation vessel 4 Methane-oxidizing bacteria and sulfate-reducing bacteria are suspended in the solution in reaction zone 9, and the content of methane-oxidizing bacteria is 1.0×10 9 CFU / ml, the content of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com