Purifying method of macroscopic body of carbon nano tube

A carbon nanotube and purification method technology, applied in the direction of carbon nanotubes, nanocarbons, etc., can solve the problems of difficult removal of metal catalysts, affecting the development and application of performance, and achieve simple, fast, low-cost, and widely used processes and methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

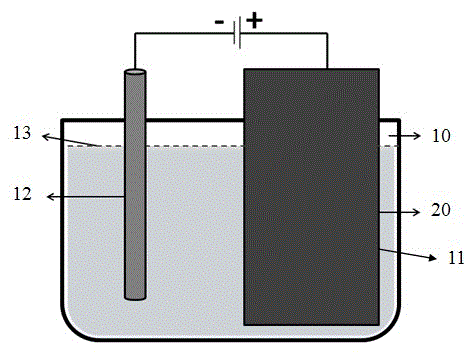

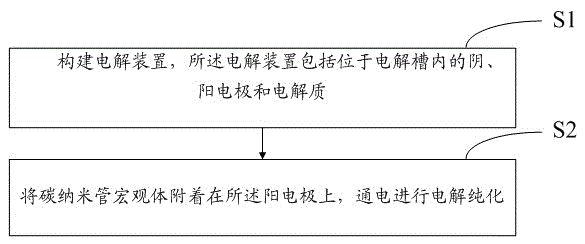

[0038] H was used with a mass fraction of 2% 2 SO 4 As the electrolyte, graphite is used as the cathode and anode electrodes, the anode electrode 11 is connected to the positive pole of the DC power supply, and the cathode electrode 12 is connected to the negative pole of the DC power supply. In this embodiment, the shape of the anode electrode 11 is flat. The carbon nanotube macroscopic body 20 is directly attached to the flat anode electrode 11, and both sides of the flat anode electrode 11 can be pasted with the carbon nanotube macroscopic body. Completely immerse the flat anode electrode attached to the carbon nanotube macroscopic body in the electrolyte, and the cathode electrode is also immersed in the electrolyte, adjust the DC power supply voltage to 2-4V, adjust the current to 0.2-0.5A, and the electrolysis time is 12-15h. During the electrolytic treatment, the electrolyte is stirred so that the residual metal catalyst in the carbon nanotube macroscopic body is oxid...

Embodiment 2

[0040] H with a mass fraction of 10% 2 SO 4 As the electrolyte, graphite is used as the cathode and anode electrodes, the anode electrode 11 is electrically connected to the positive pole of the DC power supply, and the cathode electrode 12 is electrically connected to the negative pole of the DC power supply. In this embodiment, the shape of the anode electrode 11 is flat. The carbon nanotube macroscopic body 20 is directly attached to the flat anode electrode 11, and both sides of the flat anode electrode 11 can be pasted with the carbon nanotube macroscopic body. Fully immerse the flat anode electrode attached to the carbon nanotube macroscopic body in the electrolyte, and the cathode electrode is also immersed in the electrolyte, adjust the voltage of the DC power supply to 1-3V, adjust the current to 0.1-0.3A, and the electrolysis time for 3-5h. During the electrolytic treatment, the electrolyte is stirred so that the residual metal catalyst in the carbon nanotube macro...

Embodiment 3

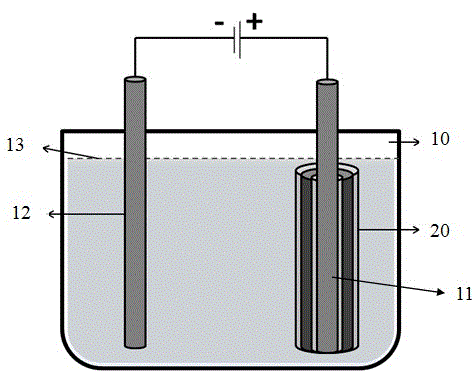

[0042] H was used with a mass fraction of 2% 2 SO 4 As the electrolyte, graphite is used as the cathode and anode electrodes. The anode electrode 11 is electrically connected to the positive pole of the DC power supply, and the cathode electrode 12 is electrically connected to the negative pole of the DC power supply. In this embodiment, the shape of the anode electrode 11 is a round rod. The carbon nanotube macroscopic body 20 is placed between two layers of clean dust-free cloth to form a sandwich structure, and one end of the carbon nanotube macroscopic body 20 is closely connected with the rod-shaped positive electrode, and then the whole carbon nanotube macroscopic body is connected to the non-woven fabric. The sandwich structure composed of dust cloth winds the rod-shaped anode 11 layer by layer, and finally wraps it with cable ties. The rod-shaped positive electrode of the carbon nanotube macroscopic body with sandwich structure is completely immersed in the electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com