Over-voltage protection element

A technology for protecting components and overvoltage, applied in the direction of overvoltage protection resistors, varistors, etc., can solve the problems of electrode short circuit, complicated steps, and high process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

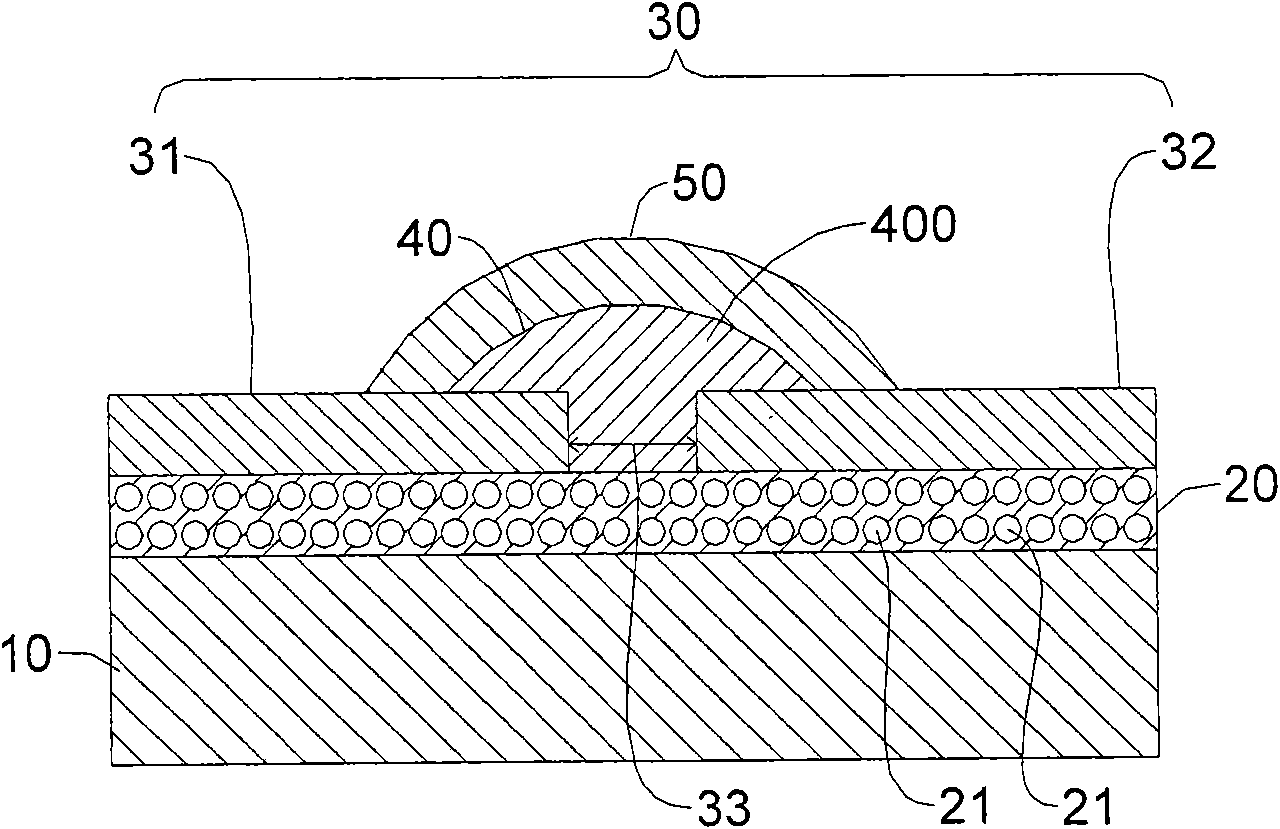

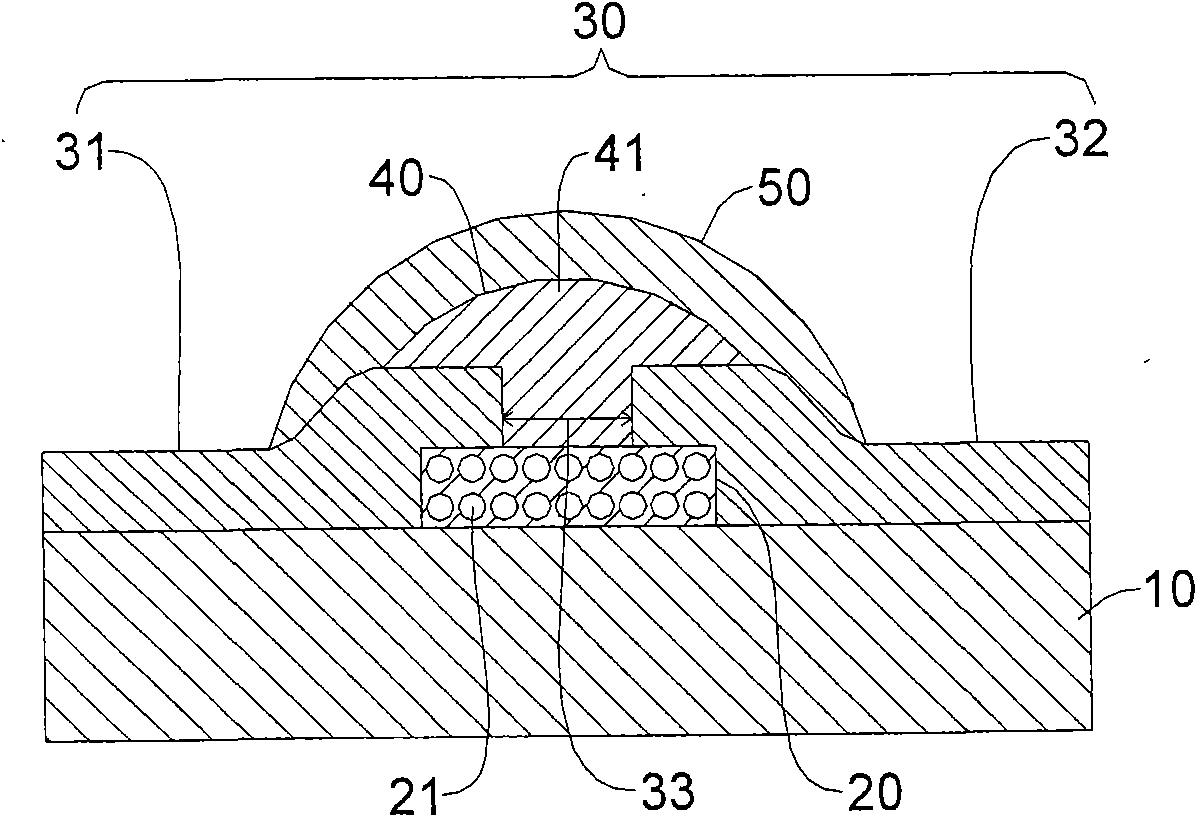

[0044] Such as figure 1 As shown, a specific embodiment of the overvoltage protection device provided by the present invention is disclosed, which mainly includes a substrate 10 , a porous material layer 20 , an electrode layer 30 and a variable impedance material layer 40 .

[0045] The porous material layer 20 is printed on the substrate 10 and has a plurality of through holes 21, and the porous material layer 20 can be a ceramic layer or a polymer layer, but not limited to these two materials.

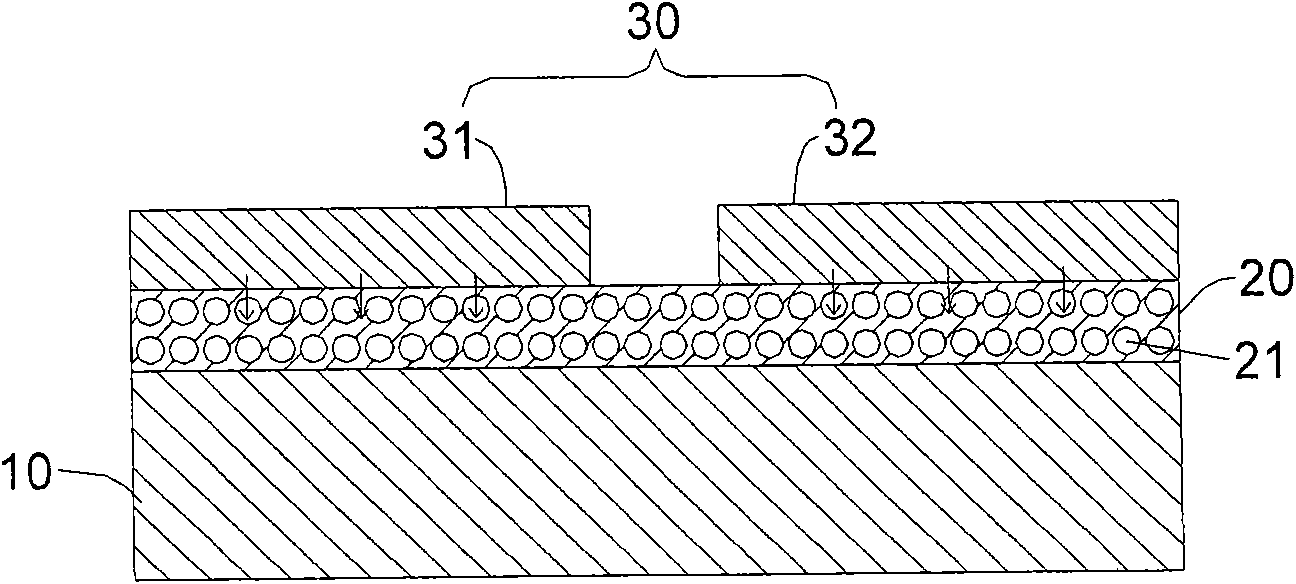

[0046] The electrode layer 30 is printed on the porous material layer 20 , the electrode layer 30 includes two electrodes 31 , 32 , and the two electrodes 31 , 32 are separated from each other with a distance 33 .

[0047] The variable impedance material layer 40 is printed on the two electrodes 31 , 32 and on the porous material layer 20 within the distance 33 between the two electrodes 31 , 32 .

[0048] Such as figure 2As shown, when the aforementioned electrode layer 30 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com