UV laser processing technology

A kind of processing technology, ultraviolet laser technology, applied in the direction of copying/marking method, printing, etc., can solve the problems such as the inability to make effect graphics mixed with various shades of colors, the inability to ensure smooth surface, and the inability to meet processing requirements, etc., to achieve improvement Added value, easy operation, and smooth surface of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

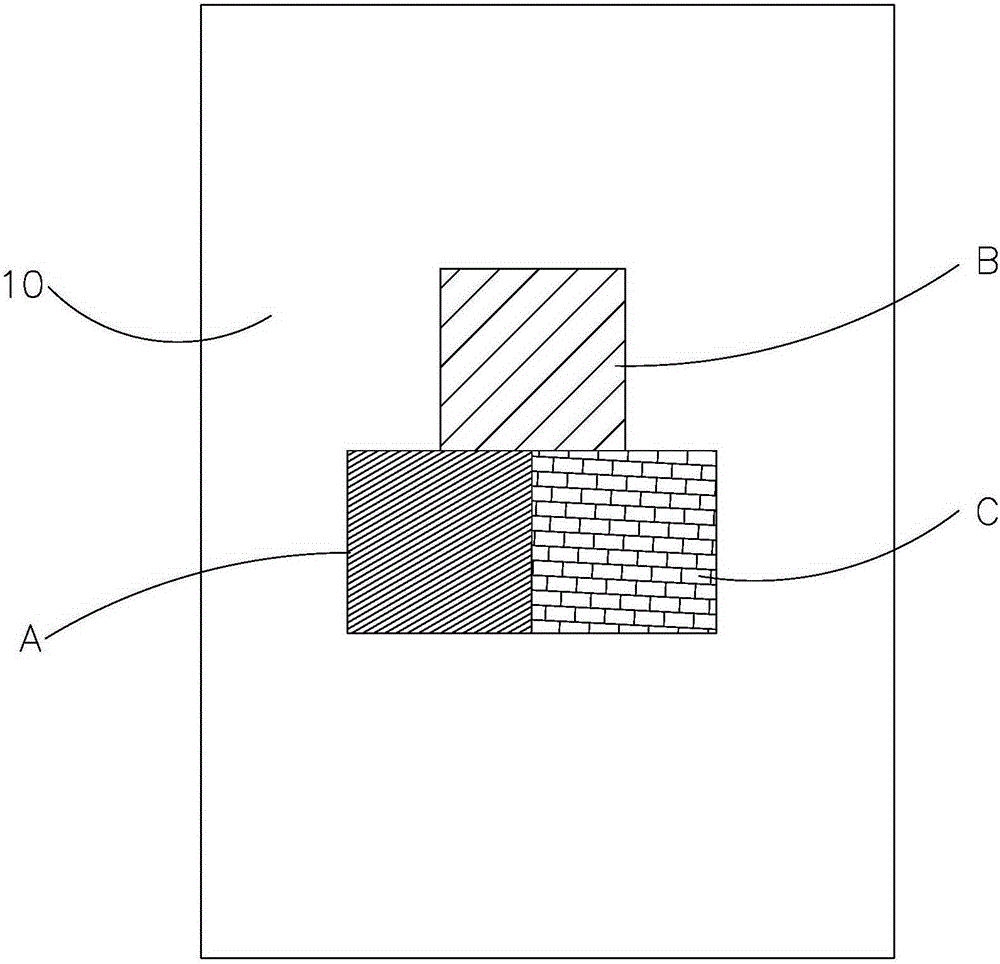

[0012] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Please refer to figure 1 , the present invention provides a kind of ultraviolet laser processing technology, and this ultraviolet laser processing technology adopts the ultraviolet laser that wavelength is 355nm band, 8W terminal pump to process workpiece 10, and this workpiece 10 can be leather, boot material etc., and adopts following steps to realize :

[0014] Step 1. Prepare marking graphics on the computer. The marking graphics can be drawn on the computer, or can be scanned on the drawing to obtain graphics. When scanning, use a two-axis high-speed scanning galvanometer system and F580mm optical scanning lens to scan get the outline of the graph;

[0015] Step 2, perform layered processing on the graphics, and divide them into different modules that are spliced to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com