A 3D printing polymer material system with precise temperature control using picosecond laser

A polymer material and 3D printing technology, applied in the field of laser 3D printing, can solve problems such as poor temperature control, warping and decomposition, and achieve the effects of short pulse time, high peak power, and preventing warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

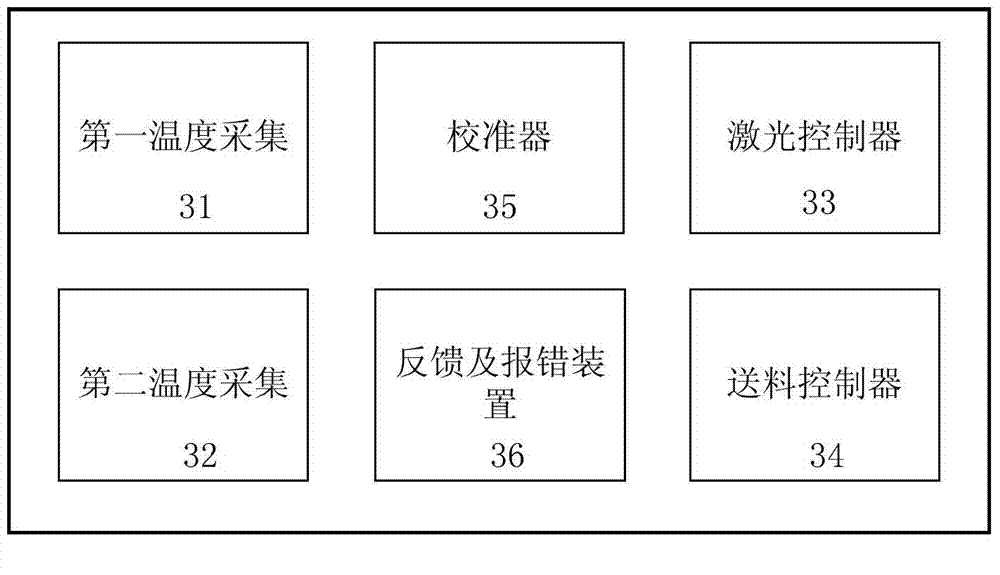

[0032] application figure 1 The picosecond laser precise temperature control 3D printing polymer material system shown in this example takes picosecond laser 3D printing nylon 66 (polyamide 66) 1mm thick strip material as an example, and its processing temperature range is 270-290°C. The thermal decomposition temperature is greater than 350°C. The most stable processing temperature is around 280°C. The picosecond laser 21 used is a fiber laser with an output wavelength of 1064 nm, a pulse width of 30 ps, a repetition rate of 50 MHz, an average power continuously adjustable between 0 and 100 W, and a focused spot diameter of 250 μm. The vibrating mirror 22 is a high-speed vibrating mirror, and the set scanning speed is 0.2 m / s. Through the laser controller 33, it is set to continuously print small grids of 2*3mm on the long-sized nylon material, but the nylon 66 material is not pierced. Both infrared thermometers use IRT-1200D fast infrared thermometer, the temperature mea...

Embodiment 2

[0035] application figure 1 As shown in the picosecond laser precise temperature control 3D printing polymer material system, this embodiment uses picosecond laser 3D printing polypropylene (PP) thermoplastic resin material. The PP material in its strip shape Φ5 is 3D printed and processed into regular particles. Because PP material has a large shrinkage rate (1% to 2.5%), it is easy to form depressions on the surface of thicker products. With general nanosecond or continuous light lasers, it is easy to accumulate heat on the surface of the material, and the depression phenomenon is difficult to eliminate. Therefore, the use of high-repetition-frequency picosecond laser 3D printing PP materials can be rapidly prototyped, and there is almost no heat accumulation on the surface of the material, which overcomes the phenomenon of surface depressions.

[0036] The picosecond laser 21 used is a fiber laser with an output wavelength of 1064 nm, a pulse width of 10 ps, a repetition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com