Special operation robot for extreme environment

A technology for operating robots and extreme environments, applied in the field of special operating robots and special operating equipment, can solve the problems of small robot load, low working efficiency, small operating arm, etc., and achieve good adaptability to extreme environments, flexible and convenient use, The effect of increasing the operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

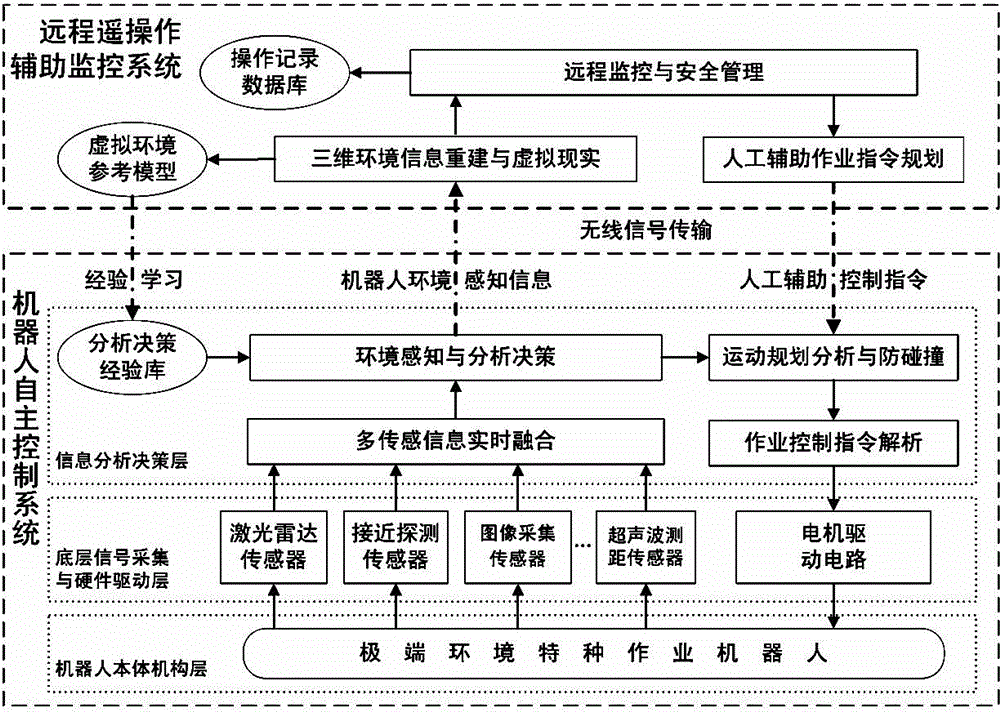

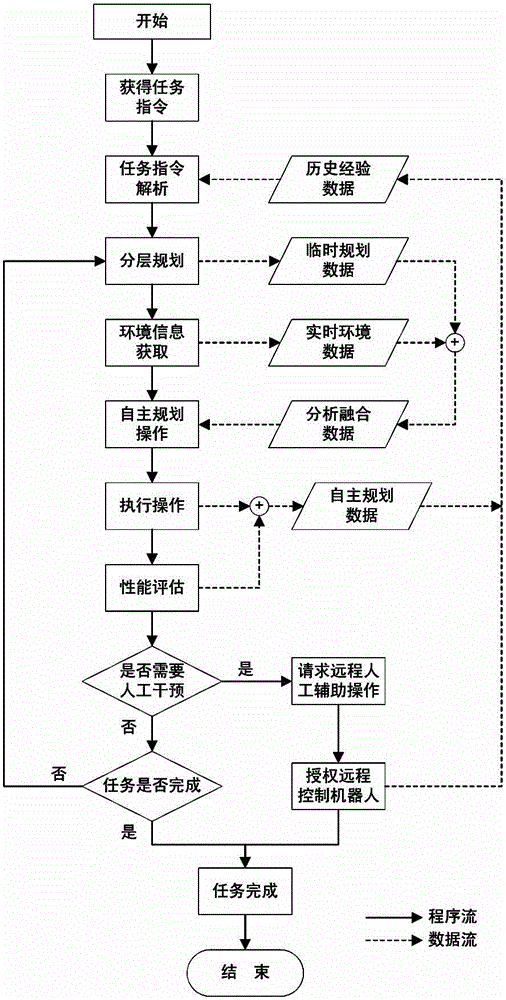

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the special operation robot oriented to extreme environments in this embodiment includes a main control cabin body 1 with a main control unit 11. The main control cabin body 1 is equipped with a chassis walking unit 2 and a folding and extending boom unit 3. The chassis walking A power supply module 21 is provided in the unit 2, and the folding and extending boom unit 3 includes a support arm base 31 and a multi-stage sequentially hinged connection support arm frame 32, the support arm base 31 is installed on the main control warehouse body 1, The first stage connection support arm frame 32 in the multi-stage connection support arm frame 32 is hingedly connected with the support arm base 31, and the end of the last stage connection support arm frame 32 is provided with a mounting seat 33 for installing the special operation mechanism 4, A first linear drive mechanism 311 is hinged on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com