A method for preparing high flatness tungsten-nickel-iron alloy plate

A tungsten-nickel-iron alloy and flatness technology is applied in the field of preparing high-flatness tungsten-nickel-iron alloy plates, which can solve the problems affecting the flatness of finished products, the limitation of total deformation, long production cycle, etc. Small, area-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

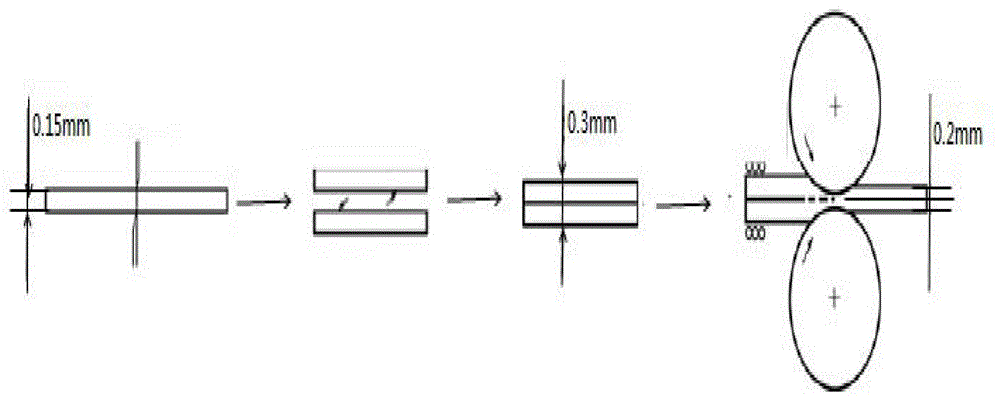

Image

Examples

Embodiment 1

[0048] The tungsten-nickel-iron alloy powder after granulation and drying is rolled into a billet, the rolling pressure is controlled at 40KN, and the rolling speed is controlled at 2.5cm / s, and the tungsten-nickel-iron alloy powder is rolled into a thin plate green body with a thickness of 1.8mm .

[0049] The prepared tungsten-nickel-iron alloy thin plate green body is placed in a sintering furnace, and sintered under the protection of hydrogen to obtain a sintered tungsten-nickel-iron alloy thin plate. The sintering temperature is 1300 ° C and the sintering time is 3 hours.

[0050] The sintered body is cold-rolled and rolled, and cold-rolled for several passes until the total deformation of the thin plate reaches 40%.

[0051] Place the cold-rolled tungsten-nickel-iron alloy sheet in a sintering furnace for refiring, the protective atmosphere is hydrogen, the refiring temperature is 1300°C, and the refiring time is 3 hours.

[0052] Repeat the first two steps until the th...

Embodiment 2

[0055] The tungsten-nickel-iron alloy powder after granulation and drying is rolled into a billet, the rolling pressure is controlled at 60KN, and the rolling speed is controlled at 2.0cm / s, and the tungsten-nickel-iron alloy powder is rolled into a thin plate green body with a thickness of 1.6mm .

[0056] The prepared tungsten-nickel-iron alloy thin plate green body is placed in a sintering furnace, and sintered under the protection of hydrogen to obtain a tungsten-nickel-iron alloy thin plate sintered body. The sintering temperature is 1300 ° C and the sintering time is 2.5 hours.

[0057] The sintered body is cold-rolled and rolled, and cold-rolled for several passes until the total deformation of the thin plate reaches 40%.

[0058] Place the cold-rolled tungsten-nickel-iron alloy sheet in a sintering furnace for refiring, the protective atmosphere is hydrogen, the refiring temperature is 1250°C, and the refiring time is 2.5 hours.

[0059] Repeat the first two steps unt...

Embodiment 3

[0062] The tungsten-nickel-iron alloy powder after granulation and drying is rolled into a billet, the rolling pressure is controlled at 80KN, and the rolling speed is controlled at 1.5cm / s, and the tungsten-nickel-iron alloy powder is rolled into a thin plate green body with a thickness of 1.2mm .

[0063] The prepared tungsten-nickel-iron alloy thin plate green body is placed in a sintering furnace, and sintered under the protection of hydrogen to obtain a sintered tungsten-nickel-iron alloy thin plate. The sintering temperature is 1250 ° C and the sintering time is 2.5 hours.

[0064] The sintered body is cold-rolled and rolled, and cold-rolled for several passes until the total deformation of the thin plate reaches 40%.

[0065] Place the cold-rolled tungsten-nickel-iron alloy sheet in a sintering furnace for refiring, the protective atmosphere is hydrogen, the refiring temperature is 1250°C, and the refiring time is 2 hours.

[0066] Repeat the first two steps until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com