Method for preparing water treatment filter material from waste red brick block

A technology of water treatment and filter material, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of small specific surface area, rough surface, and low porosity, and achieve large specific surface area, rough surface, and porosity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

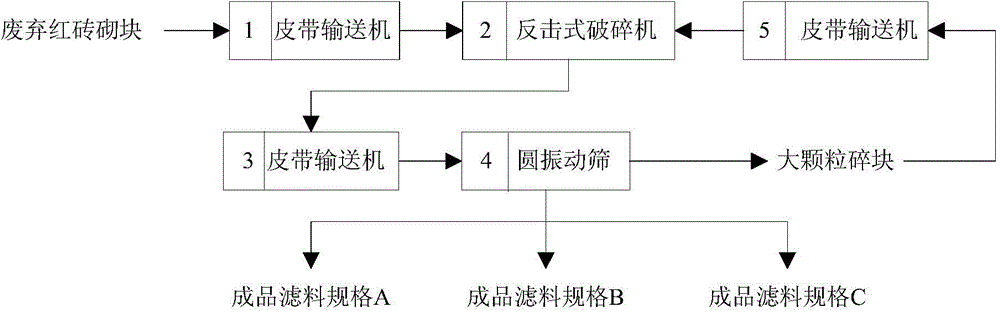

[0031] as attached figure 1 As shown, 10 tons of waste red brick blocks from construction waste are sent to the impact crusher 2 through the belt conveyor 1 for crushing; the crushed components are sent to the circular vibrating screen 4 by the belt conveyor 3 for screening. Obtain large particle fragments, finished filter material specification A, finished filter material specification B, finished filter material specification C, and large particle fragments are sent back to the impact crusher 2 by the belt conveyor 5 for secondary crushing.

[0032] The characteristics of the discarded red brick blocks of construction waste used in the present invention are: the maximum diameter is no more than 250mm, and it is a kind of construction waste.

[0033] The main parameters of belt conveyor 1, belt conveyor 3 and belt conveyor 5 adopted in the present invention are: belt width 400mm, conveying length 12-20m, power 2.2-4kW, conveying speed 1.25-2.0m / s, conveying capacity 10-20t / h...

Embodiment 2-5

[0041] Embodiments 2-5 have the same properties as the construction waste waste red brick blocks of Embodiment 1, but the crushing quality is different. The equipment belt conveyor 1, impact crusher 2, belt conveyor 3, circular vibrating screen 4, and belt conveyor 5 have the same characteristics. The yields of the finished filter material specification A, the finished filter material specification B, and the finished filter material C are different. The output of the finished filter material obtained in Examples 1-5 is shown in Table 1, and the physical and chemical performance parameters of the finished filter material are shown in Table 2.

[0042] Table 1

[0043]

[0044] Table 2

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com