Carbon nanotube assembly and viscoelastic body using same

A technology of carbon nanotubes and aggregates, applied in the direction of carbon nanotubes, oriented carbon nanotubes, nanocarbons, etc., can solve problems such as difficult operation and particle collection, and achieve excellent operability and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] On a silicon wafer (manufactured by Silicon Technology) as a substrate, an Al thin film (thickness 10 nm) was formed using a sputtering apparatus (manufactured by ULVAC, RFS-200). On this Al thin film, an Fe thin film (thickness: 0.35 nm) was vapor-deposited using a sputtering apparatus (manufactured by ULVAC, RFS-200).

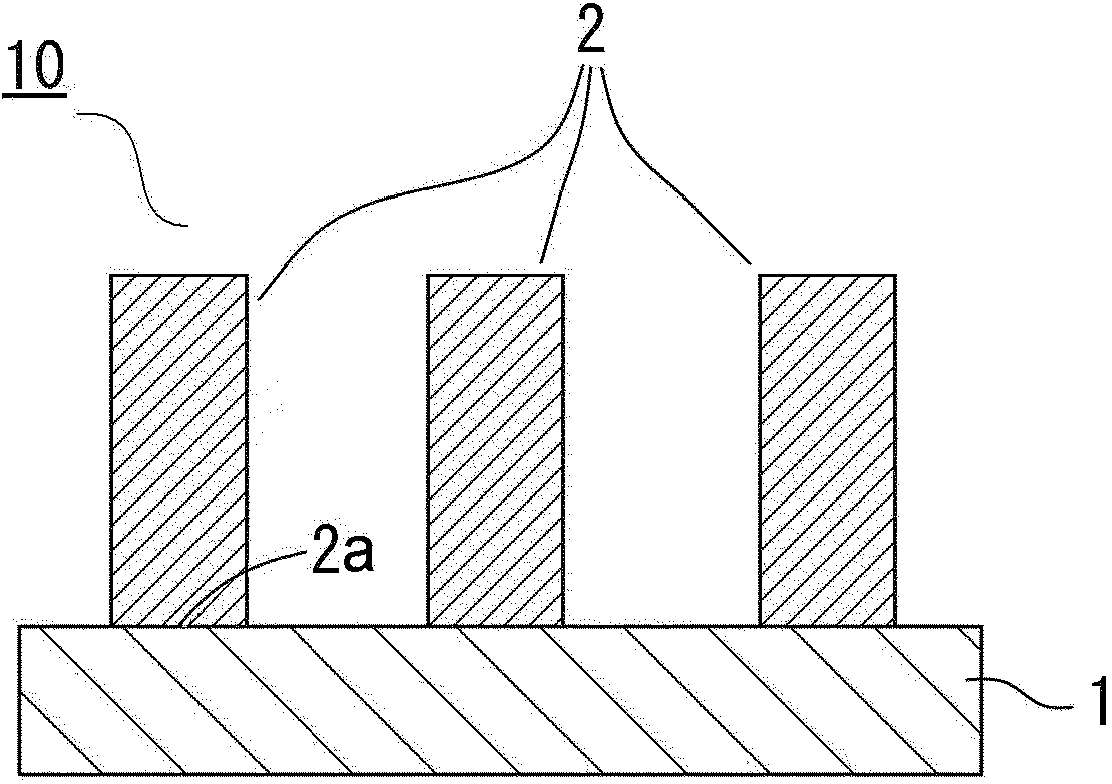

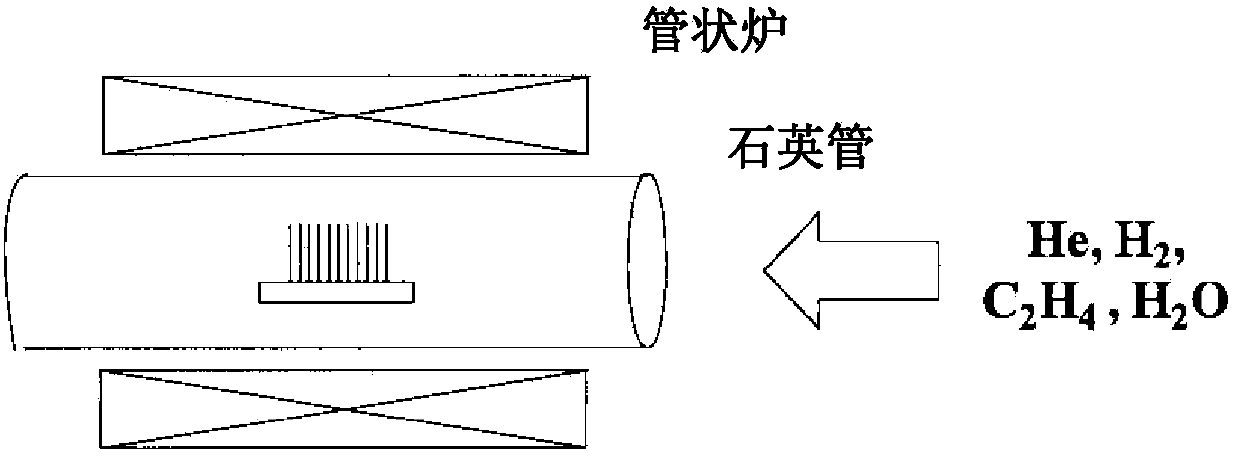

[0116] Thereafter, the substrate was placed in a 30 mmΦ quartz tube, and a mixed gas of helium / hydrogen (90 / 50 sccm) with a water content of 600 ppm was flowed in the quartz tube for 30 minutes to replace the inside of the tube. Thereafter, the temperature inside the tube was raised to 765°C using a tubular electric furnace and stabilized at 765°C. Keep the temperature at 765°C, fill the tube with helium / hydrogen / ethylene (85 / 50 / 5sccm, moisture content 600ppm) mixed gas, and let it stand for 1 minute to grow carbon nanotubes on the substrate to obtain carbon nanotubes oriented in the length direction. Carbon nanotube aggregates (1).

[0117] The leng...

Embodiment 2

[0121] A carbon nanotube aggregate (2) in which carbon nanotubes were oriented in the longitudinal direction was obtained in the same manner as in Example 1 except that the thickness of the Fe thin film was 1 nm.

[0122] The length of the carbon nanotubes included in the carbon nanotube aggregate (2) was 30 μm.

[0123] In the distribution of the number of layers of carbon nanotubes included in the carbon nanotube aggregate (2), the mode exists in two layers, and the relative frequency is 75%.

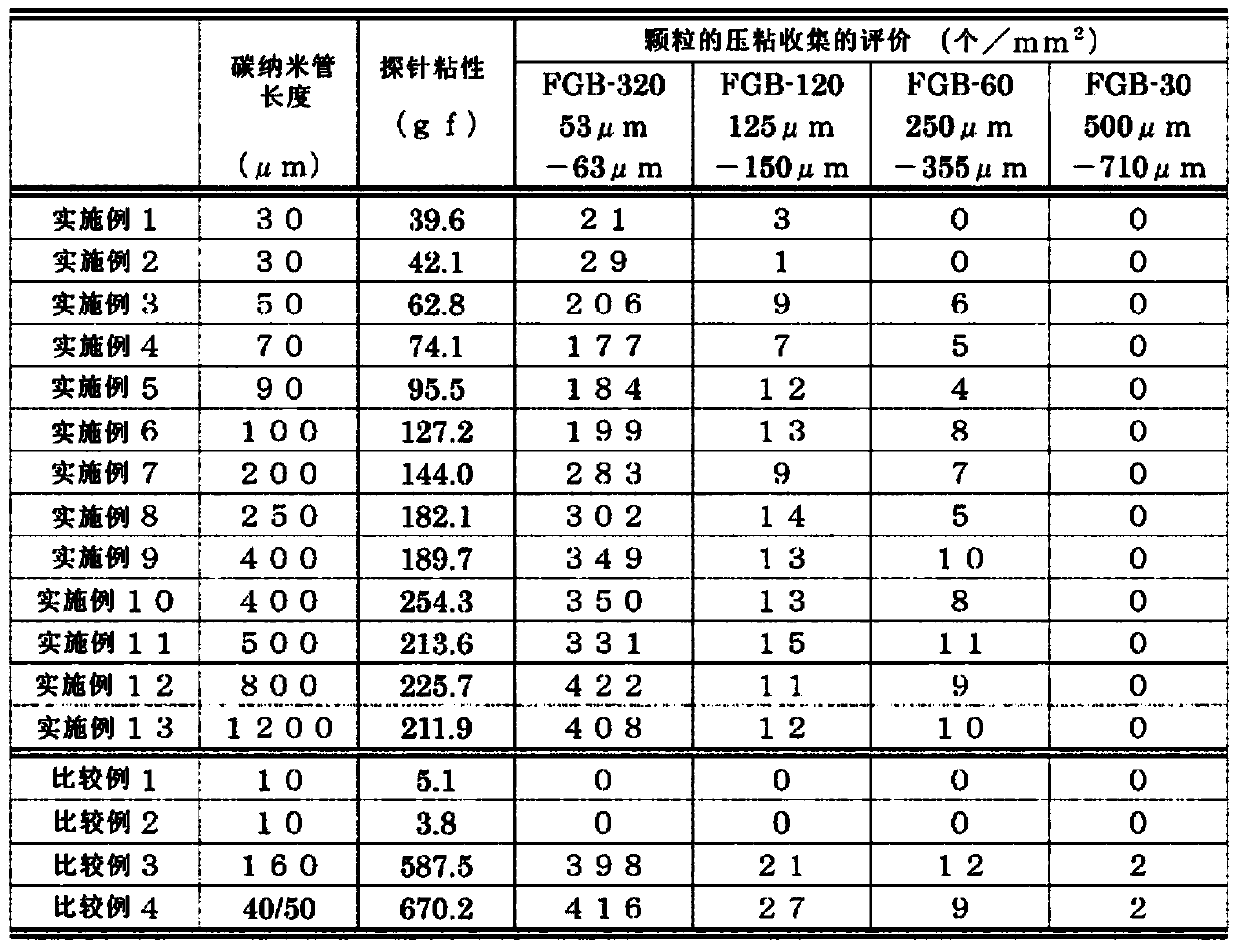

[0124] The obtained aggregate of carbon nanotubes (2) was used as the viscoelastic body (2), and various evaluations were performed, and the results are summarized in Table 1 and Table 2.

Embodiment 3

[0126] Except that the standing time after the helium / hydrogen / ethylene (85 / 50 / 5sccm, moisture content 600ppm) mixed gas is filled in the tube is 3 minutes, carry out in the same manner as in Example 2, and obtain carbon nanotubes in which the carbon nanotubes are oriented in the longitudinal direction. Aggregate (3).

[0127] The length of the carbon nanotubes included in the carbon nanotube aggregate (3) was 50 μm.

[0128] In the distribution of the number of layers of carbon nanotubes included in the carbon nanotube aggregate (3), the mode exists in two layers, and the relative frequency is 75%.

[0129] Various evaluations were performed using the obtained aggregate of carbon nanotubes (3) as the viscoelastic body (3), and the results are summarized in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com