Novel three-dimensional nano carbon/stainless steel mesh compound biological anode as well as preparation method and application thereof

A stainless steel mesh, three-dimensional nanotechnology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as reducing the corrosion resistance of stainless steel substrates and application limitations of nano-carbon/stainless steel composite electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

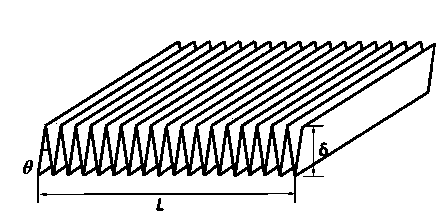

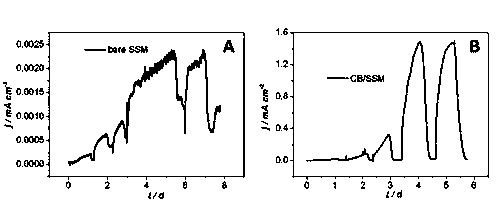

[0025] 1. Preparation and power generation performance test of single-layer nano-carbon / stainless steel mesh composite anode

[0026] Soak 304 stainless steel mesh with 50 mesh in 1 mol / L sulfuric acid solution for 1 hour, clean it with distilled water, immerse it in 5 g / L carbon black / alcohol dispersion, take it out and dry it, and repeat soaking / drying step 3 times to obtain a single-layer nano-carbon / stainless steel mesh composite anode.

[0027] Select stainless steel nets of different materials or meshes, and repeat the above steps to prepare nano-carbon / stainless steel net composite anodes with different pore sizes.

[0028] For the test conditions of the anode performance, see [Guanghua He, Yanli Gu, Shuijian He, Uwe Schreoer, Shuiliang Chen, Haoqing Hou. Effect of fiber diameter on the behavior of biofilm and anodic performance of fiber electrodes in microbial fuel cells. Bioresour. Technol. 10763-10766 (2011)], the specific experimental process is as follows: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com