Porous current collector metal material continuous processing method

A technology for metal materials and current collectors, applied in the field of continuous processing of porous metal materials for current collectors, can solve problems such as unsatisfactory arrangement, uneconomic benefits, and excessive waste, and achieve environmental protection treatment costs, good perforation processing quality, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

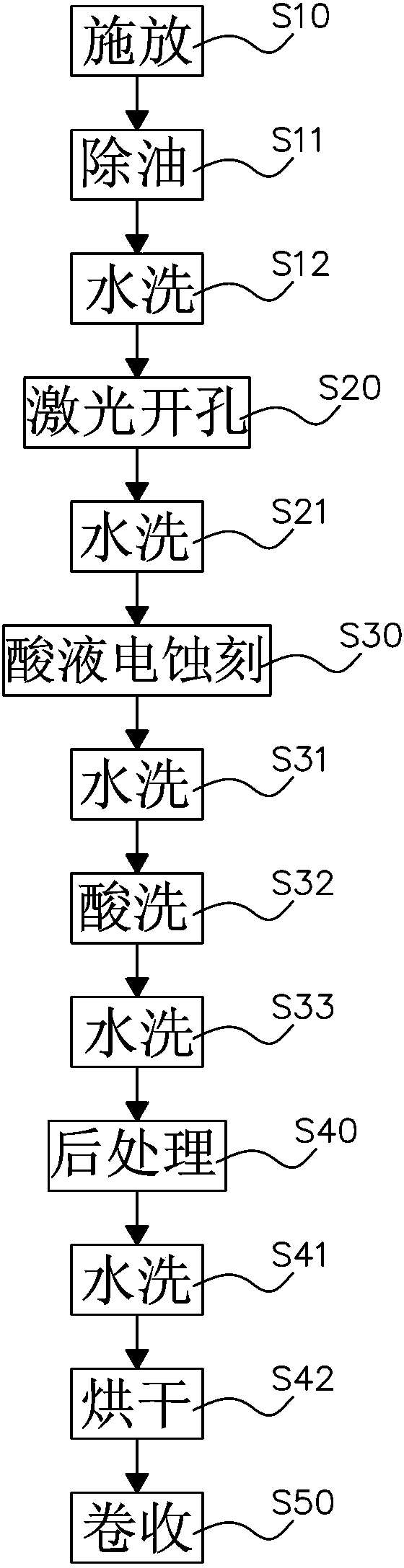

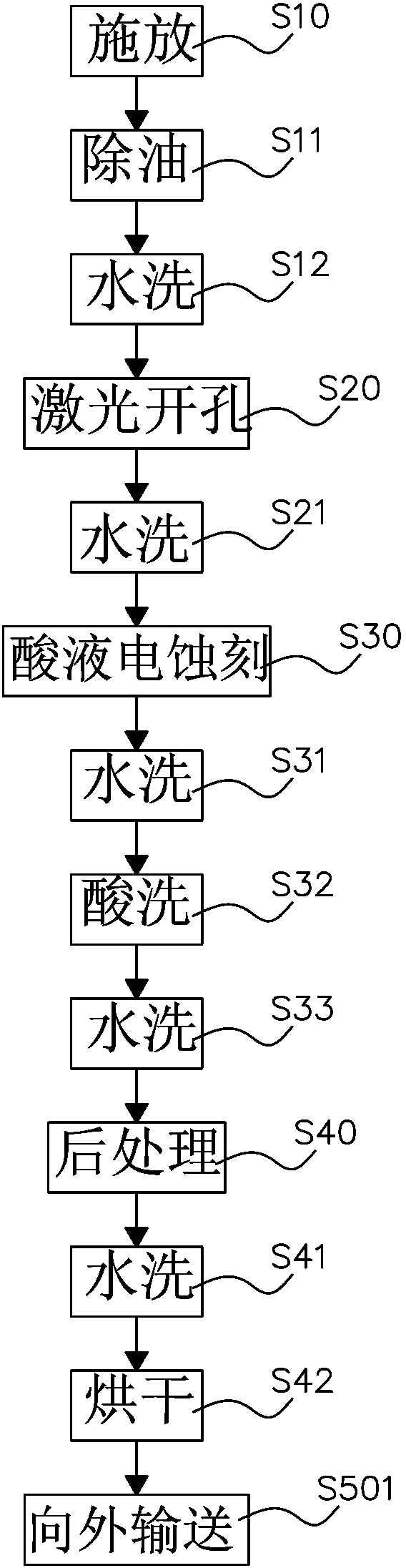

[0047] Please refer to Figure 1, it can be seen that the first embodiment of the present invention is applied to the roll-to-roll processing method, and its main processing flow includes: step S10 of casting, step S20 of laser opening, step S30 of acid etching, A post-processing step S40 and a winding step S50; wherein the releasing step S10 enables the sheet metal material to be gradually released from a retracted state, or gradually released through the previous feeding device, so as to continuously supply subsequent processing needs , the sheet-shaped metal material can also be kept in a continuous feeding state during the processing time; then, the metal material can be subjected to a step of degreasing S11 and a step of water washing S12 respectively to clean the sheet-shaped metal material surface.

[0048] In step S20 of laser opening, the optical fiber laser is used in conjunction with the galvanometer controlled by the preset program to perform perforation processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com