Synthesizing method for dual anode material

A synthesis method and positive electrode material technology, applied in the direction of electrical components, battery electrodes, secondary batteries, etc., can solve the problems of unstable discharge performance, unstable material performance, uneven sintering, etc., achieve excellent processing performance and avoid cation dislocation , the effect of uniform component distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

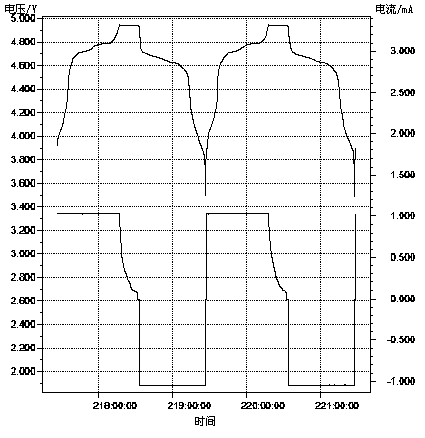

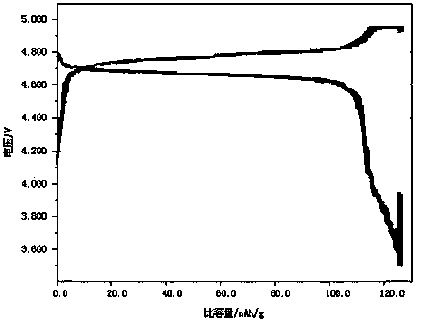

Image

Examples

Embodiment 1

[0021] A kind of synthetic method of binary cathode material, process step is, the lithium hydroxide (purity is 99.9% LiOH, with Li + 1mol), 46.36g of nickel hydroxide ((Ni(OH) 2 , with Ni 2+ 0.5mol), 130.47g of manganese dioxide (purity is 99.95% MnO 2 , with Mn 4+ 1.5mol in total) was added to the high-energy ball mill with a metal ion molar ratio of 1:0.5:1.5. The grinding medium in the ball mill is zirconia ceramic balls (ball diameter grinding 1mm). The weight ratio of grinding balls to raw materials is 10:1. In a planetary ball mill with revolution and autopropagation, dry the raw material for 10 hours at a revolution speed of 10,000 r / min. After a high-energy grinding process, LiNi can be obtained. 0.5 mn 1.5 o 4 finished product.

Embodiment 2

[0023] A kind of synthetic method of binary cathode material, process step is, the lithium carbonate of 369.5g (purity is 99.98% Li 2 CO 3 , with Li + 10mol), 374.32g of nickel oxide (NiO with a purity of 99.77%, expressed as Ni 2+ 5mol), 1145.32g of trimanganese tetroxide (purity is 99.89% Mn 3 o 4 , with Mn 4+ and Mn 2+ 15mol in total) was added to the high-energy ball mill at a metal ion molar ratio of 1:0.5:1.5. The grinding medium in the ball mill is zirconia ceramic balls (ball diameter milling 10mm). The weight ratio of grinding balls to raw materials is 50:1. In a planetary ball mill with revolution and autopropagation, dry the raw materials for 50 hours at a revolution speed of 5000 rpm, and through a high-energy grinding process, LiNi can be obtained 0.5 mn 1.5 o 4 finished product.

Embodiment 3

[0025] A kind of synthetic method of binary cathode material, process step is, the lithium nitrate (purity is 99.91% LiNO of 345.06g 3 , with Li + 5mol), 232.14g of nickel nitrate (purity is 99.83% Ni (NO 3 ) 2 , with Ni 2+2.5mol), 652.35g of manganese dioxide (purity is 99.95% MnO 2 , with Mn 4+ 7.5mol in total) was added to the high-energy ball mill at a molar ratio of metal ions of 1:0.5:1.5. The grinding medium in the ball mill is zirconia ceramic balls (ball diameter mill 20mm). The weight ratio of grinding balls to raw materials is 100:1. In a planetary ball mill with revolution and autopropagation, the raw material is dry-milled for 100 hours at a revolution speed of 100 rpm. After a high-energy grinding process, LiNi can be obtained. 0.5 mn 1.5 o 4 finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com