Preparation method for lithium ion battery positive electrode material with 4.5 V voltage platform

A lithium-ion battery and cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of no practical reports, etc., and achieve the effects of small uniformity difference, high electrochemical activity, and batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

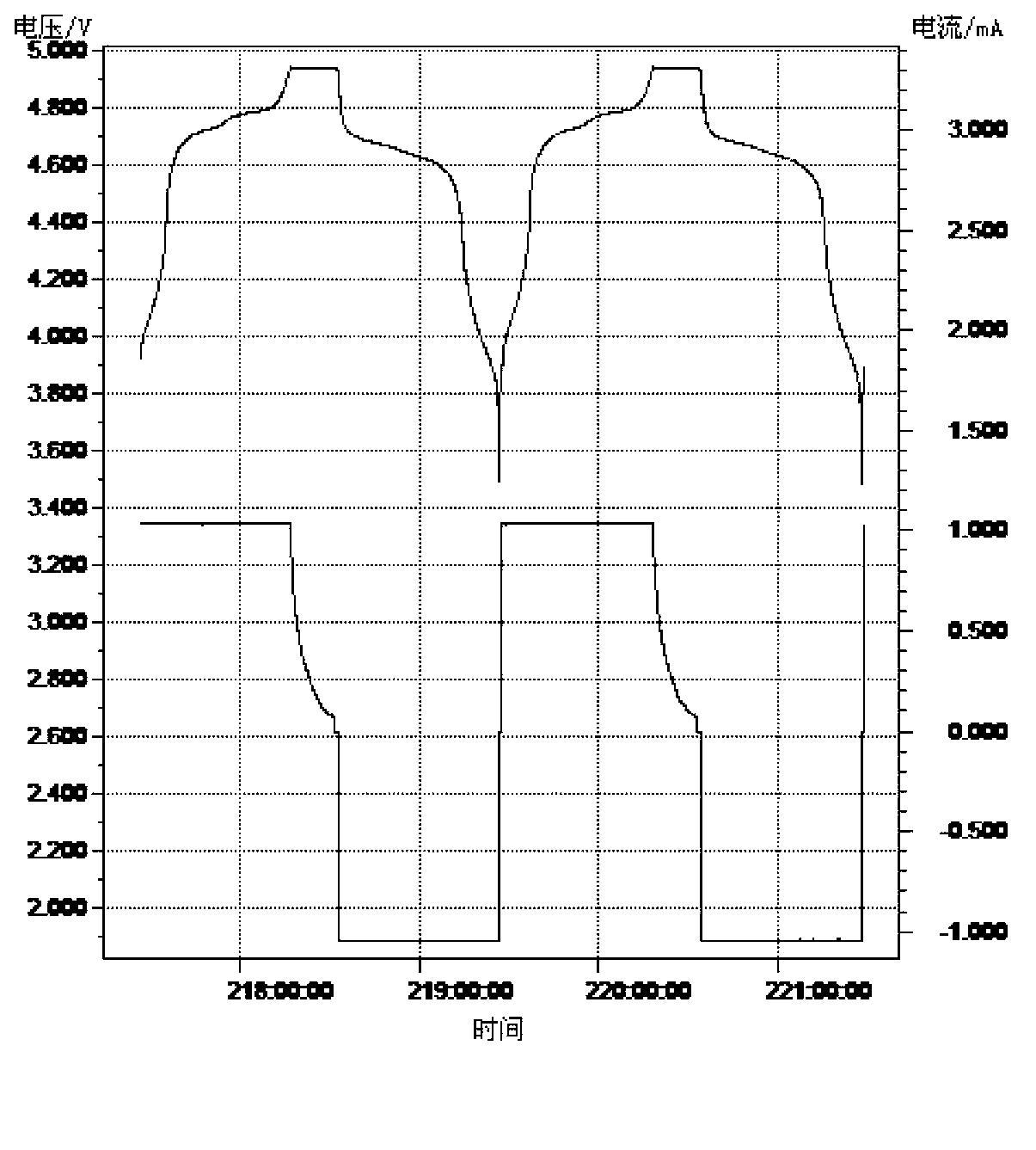

Image

Examples

Embodiment 1

[0025] 54.9g lithium sulfate (Li 2 SO 4 , with Li + 1mol), 77.3g anhydrous nickel sulfate (NiSO 4 , 0.5mol), 226.4g anhydrous manganese sulfate (MnSO 4 , 1.5mol) prepared, dissolved with an appropriate amount of pure water and stirred evenly, added water to make a 15L solution (total weight about 15256g. At this time, the concentration of metal ions in the solution was 0.2mol / L. After dissolving, add 54.17g (mass percentage concentration 22~28%) ammonia water as a complexing agent. Then put the solution into a sealed container. Heat the solution to 150°C, and in a stirring state, use a high-pressure pump to continuously add a lithium hydroxide solution with a concentration of 0.5mol / L. Until the pH value reaches 10. Stir at constant temperature for 10 hours, lower the temperature, filter and wash the product to remove soluble sulfate ions and metal ions, and dry at 120°C to obtain LiNi 0.5 mn 1.5 o 4 Material.

[0026] attached figure 1The electron micrograph of the mi...

Embodiment 2

[0028] 54.9Kg lithium sulfate (Li 2 SO 4 , with Li + 1000mol), 77.3Kg anhydrous nickel sulfate (NiSO 4 , 500mol), 226.4Kg anhydrous manganese sulfate (MnSO 4 , 1500mol) prepared, dissolved with an appropriate amount of pure water, stirred evenly, and added water to make a 600L solution (total weight about 898.2Kg). At this time, the concentration of metal ions in the solution was 5 mol / L. After dissolving, add 44.91Kg ethylenediaminetetraacetic acid (EDTA) as complexing agent. Then put the solution in an airtight container. Heat the solution to 200°C, and continuously add sodium hydroxide solution with a concentration of 5 mol / L with a high-pressure pump under stirring until the pH value reaches 13. Stir at constant temperature for 24 hours, lower the temperature, filter and wash the product to remove soluble sulfate ions and metal ions, and dry at 150°C to obtain LiNi 0.5 mn 1.5 o 4 Material. The crystal form of product, particle size are the same as embodiment 1. ...

Embodiment 3

[0031] 68.9g lithium nitrate (LiNO 3 , with Li + 1mol), 91.3g anhydrous nickel nitrate (Ni(NO 3 ) 2 , 0.5mol), 268.4g anhydrous manganese nitrate (Mn(NO 3 ) 2 , 1.5mol) is prepared, dissolved with an appropriate amount of pure water, stirred evenly, and added with water to make a 3L solution (total weight about 3205g). At this time, the concentration of metal ions in the solution is 1 mol / L. Add 32.05g of thiocyanic acid as complexing agent. Then put the solution in an airtight container. Heat the solution to 180°C, and continuously add sodium hydroxide solution with a concentration of 2 mol / L with a high-pressure pump under stirring until the pH value reaches 11. Stir at constant temperature for 20 hours, lower the temperature, filter and wash the product to remove soluble sulfate ions and metal ions, and dry at 130°C to obtain LiNi 0.5 mn 1.5 o 4 Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com