Vacuum photoelectric direct-reading spectrometer

A photoelectric direct reading and spectrometer technology, applied in instruments, scientific instruments, electrical excitation analysis, etc., can solve the problems of wasting energy, unable to analyze immediately, reducing structural hardness, etc., to avoid easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

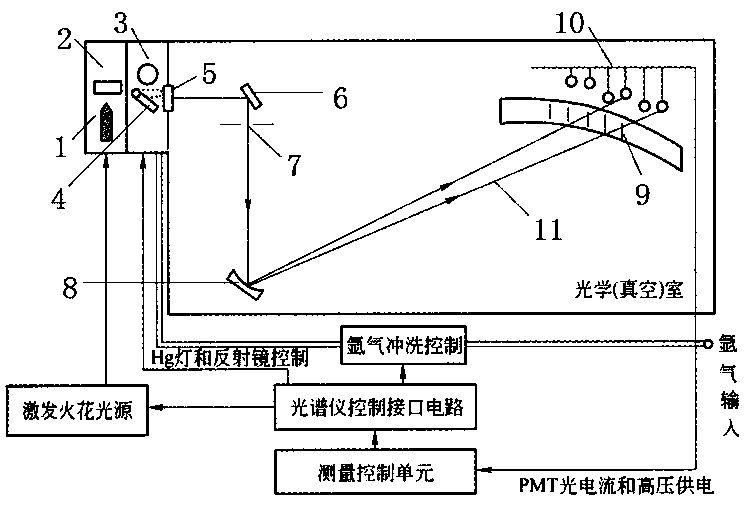

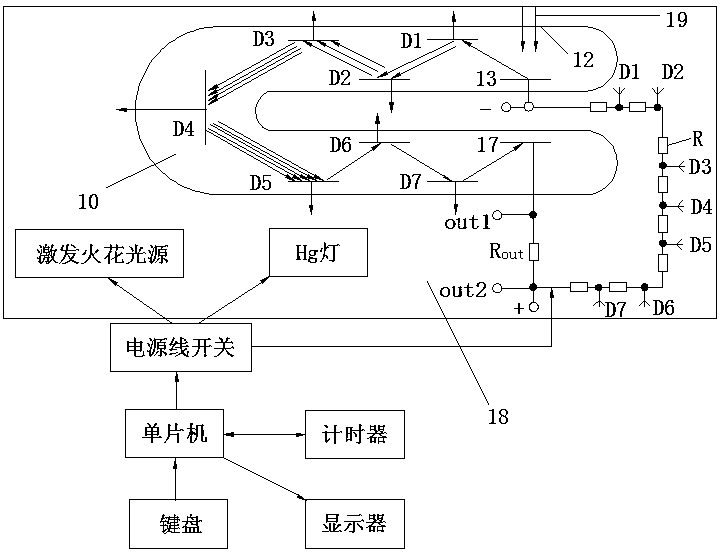

[0019] Such as image 3 As shown, a vacuum photoelectric direct-reading spectrometer includes a vacuum photoelectric direct-reading spectrometer body 18. It should be noted that, for the simplicity of the picture, image 3 The entire structure of the vacuum photoelectric direct reading spectrometer body 18 is not shown, and the vacuum photoelectric direct reading spectrometer body 18 is in the image 3 In , only a rectangular box is used to illustrate, and only the improved related structure is shown. For the specific structure, please refer to figure 1 As shown, the combustion chamber in the upper left corner is included, and the electrode 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com