Flexible high-temperature raster strain foil for two-dimensional stress detection

A two-dimensional strain and strain gauge technology, applied in measurement devices, optical devices, instruments, etc., can solve the problem that fiber grating strain gauges cannot detect two-dimensional strains, and achieve quasi-distributed multi-point measurement, low cost, Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

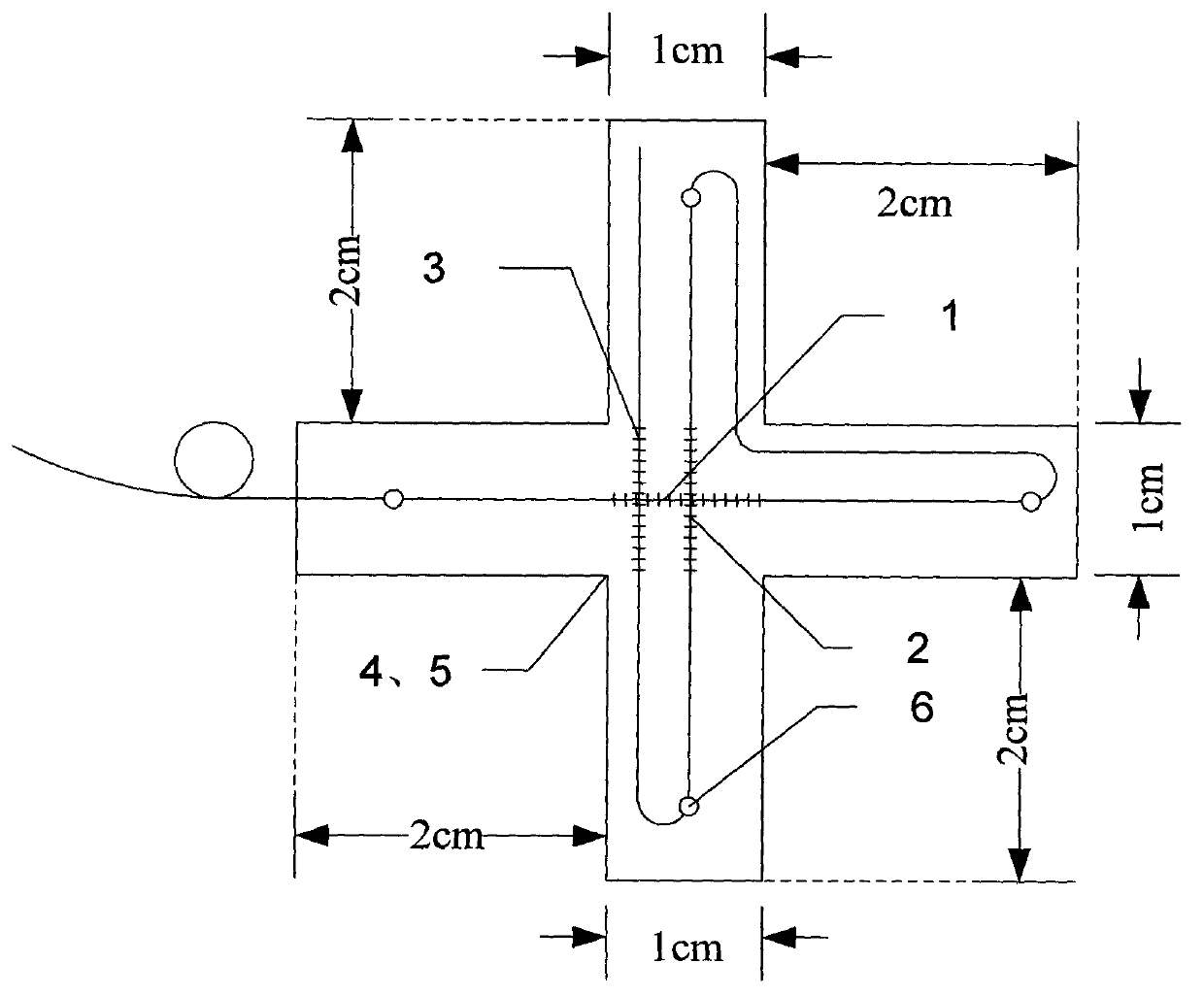

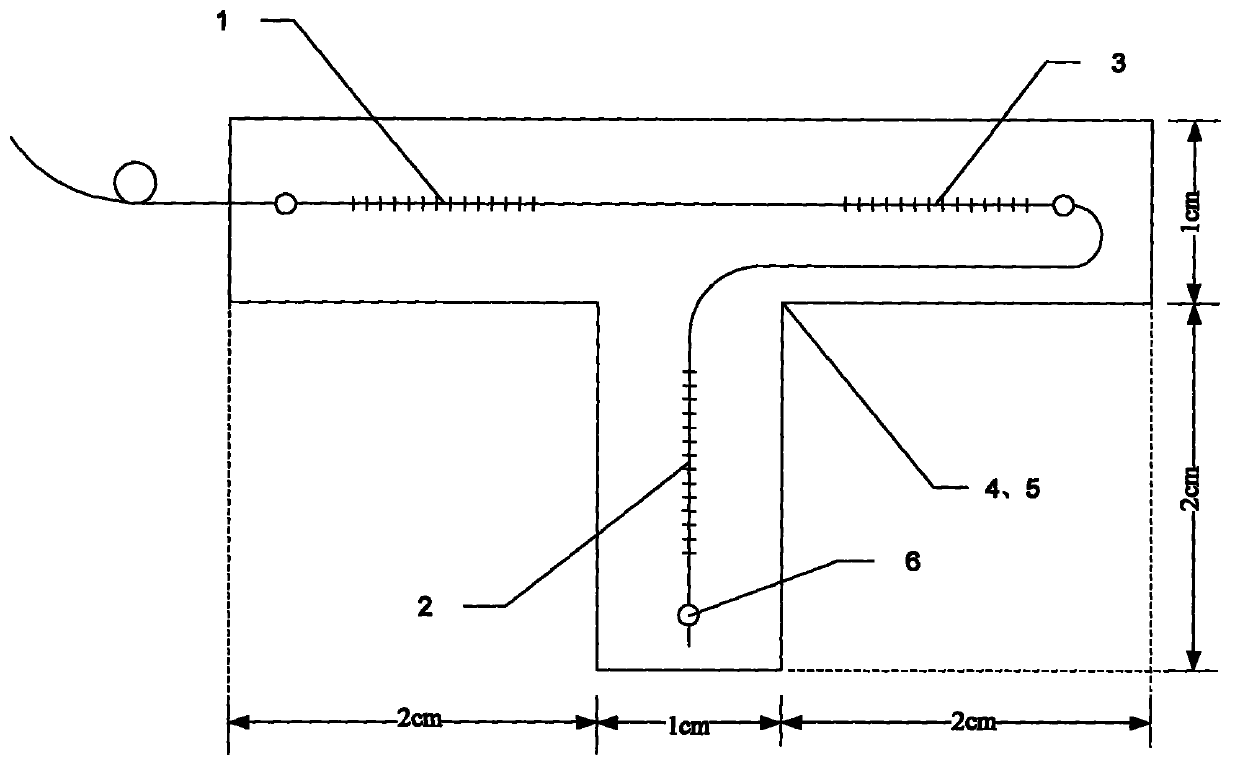

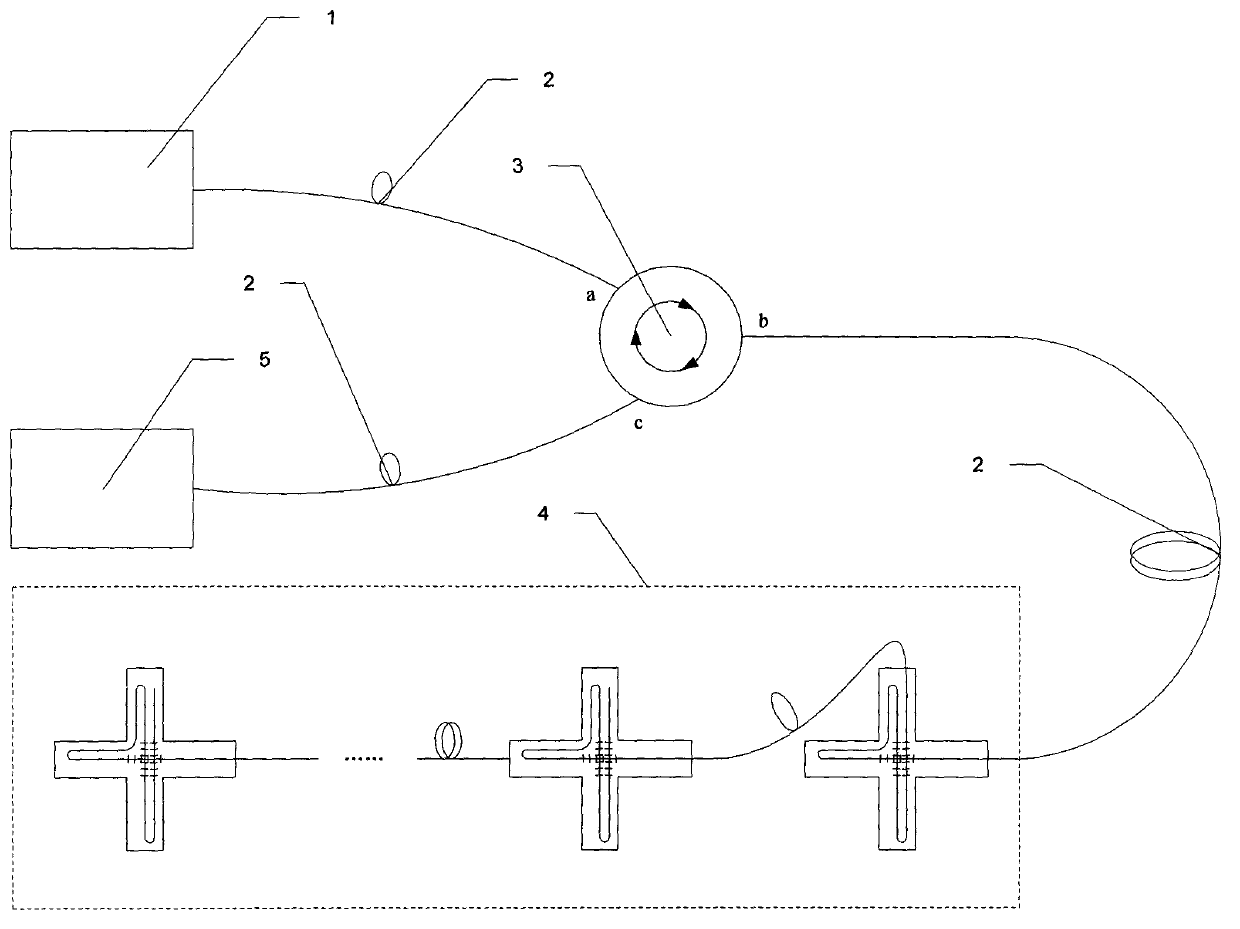

[0020] combine figure 1 , the present invention is a kind of high-temperature-resistant fiber grating strain gauge capable of detecting two-dimensional strain on the surface of complex components, which is composed of a "ten"-shaped metal sheet substrate (4), a high-temperature Bragg grating A (1), a high-temperature Bragg grating B (2 ), high temperature Bragg grating C (3) and high temperature resistant cover layer (5); the three high temperature Bragg gratings are fixed on the substrate (4) by high temperature glue, and the high temperature resistant cover layer (5) is pasted on the three by high temperature glue only on the high temperature Bragg grating; the optical serial connection between the three high temperature Bragg gratings has different characteristic wavelengths; the fiber Bragg grating strain gauge is fixed on the surface of the component at the weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com