Connection device for cooling water circuit sealing of high heat-loaded optical components in ultra-high vacuum

A technology of ultra-high vacuum and optical components, which is applied to engine components, engine seals, mechanical equipment, etc., can solve the problems of inconvenient workload and achieve the effect of optimizing design and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

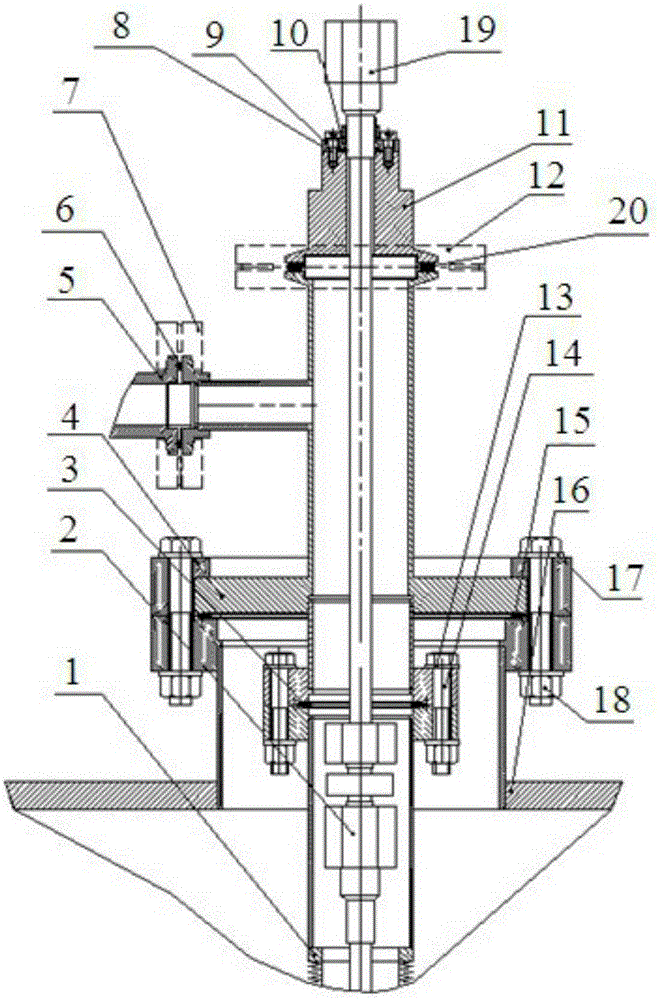

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] The connection device for the cooling water circuit seal of high thermal load optical components in ultra-high vacuum, the specific production and installation process is as follows:

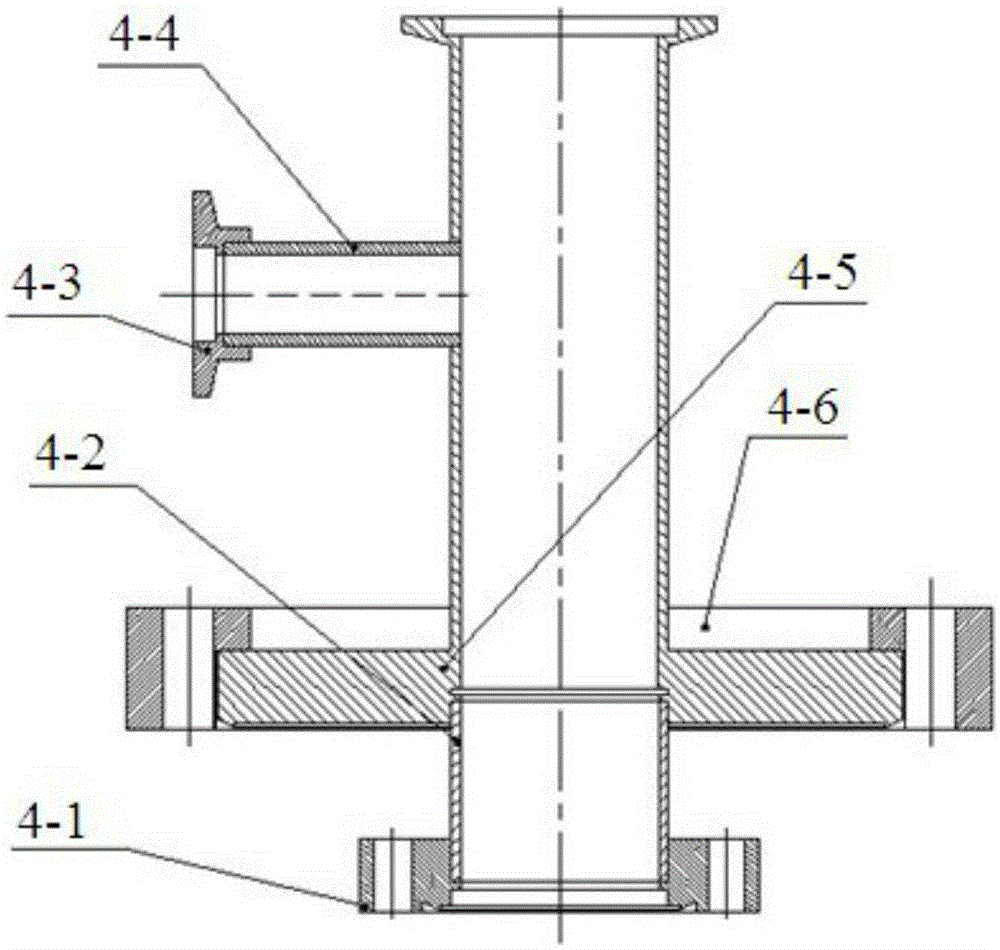

[0021] 1) if figure 1 As shown, first process the multifunctional conversion welding assembly 4, which passes through A knife-edge flange 4-1, A flange connecting pipe 4-2, B flange 4-3, B flange connecting pipe 4-4, combined flange 4-5 and the optimized combination of loose flange outer ring 4-6. Weld the A knife-edge flange 4-1 with the A flange connecting pipe 4-2, and weld the B flange 4-3 with the B flange connecting pipe 4-4. Install the outer ring 4-6 of the loose flange with the combined flange 4-5, then weld the A flange connecting pipe 4-2 to the lower part of the combined flange 4-5, and weld the B flange connecting pipe 4-4 to the On the cylindrical surface of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com