Mining active magnetic water dust-settling method and system

A magnetized water, active technology, applied in the fields of dust prevention, mining equipment, earthwork drilling, etc., can solve the problems of low dust removal rate, low dust removal efficiency, combustion and explosion, etc., to increase the contact area, enhance the atomization effect, Guaranteed effect of dust suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

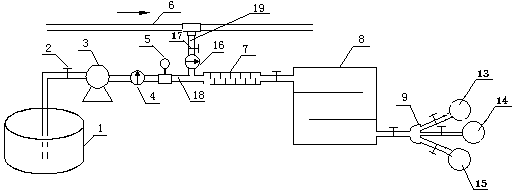

[0020] like figure 1 Shown, a kind of mining active magnetized water dust suppression method, the dust suppression steps are as follows:

[0021] A. Add tensio-active agent in active agent addition barrel 1;

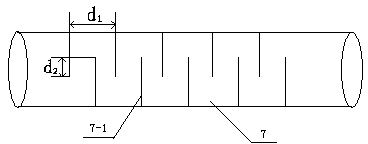

[0022] B. Make active agent suction pipe 18 extract surfactant from active agent adding barrel 1 by pneumatic liquid driving pump 3, and mix uniformly in mixer 7 with the water flowing in in static pressure water supply pipe 6;

[0023] C. The water pressure in the static pressure water supply pipe 6 and the pressure provided by the pneumatic liquid driving pump 3 jointly flow the formed active water into the "Z" shaped magnetization channel of the magnetizer 8, and the permanent magnet forms a magnetic field of 350mT ~ 500mT to activate the active water. The water is magnetized to vertically cut the lines of magnetic induction;

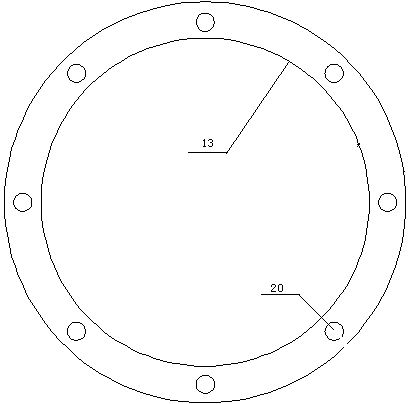

[0024] D. The magnetized active ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com