A three-roll calender for textiles and a textile calendering method

A technology for textiles and calenders, which is applied to textiles, papermaking, and fabric surface trimming. It can solve the problems of low friction coefficient and poor twisting effect of nylon rollers, and achieve high roller surface friction, uniform pressure, and good elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

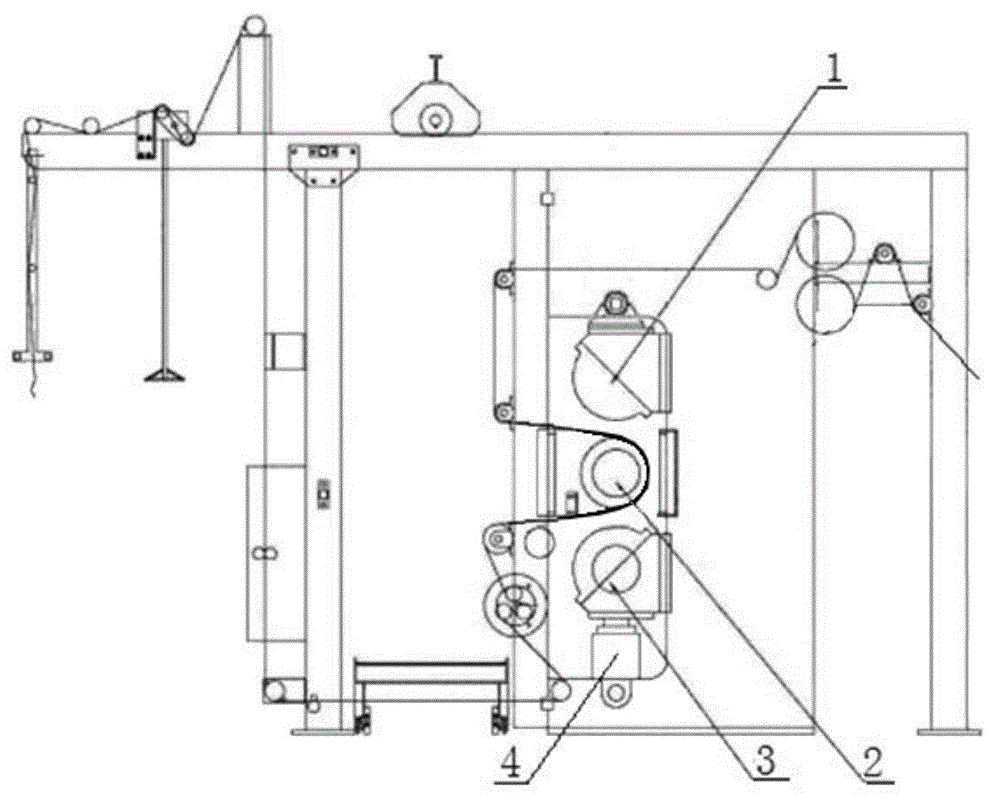

[0026] The three-roll calender of the present invention includes a frame, a cloth feeding device, a cloth discharging device, a cooling device, three rolls and a pressurized oil cylinder 4 . The frame, cloth feeding device, cloth discharging device and cooling device are all the same as the existing three-roll calender. The improvement of the present invention lies in the material, type, combination mode and cloth traveling track of the three rolls.

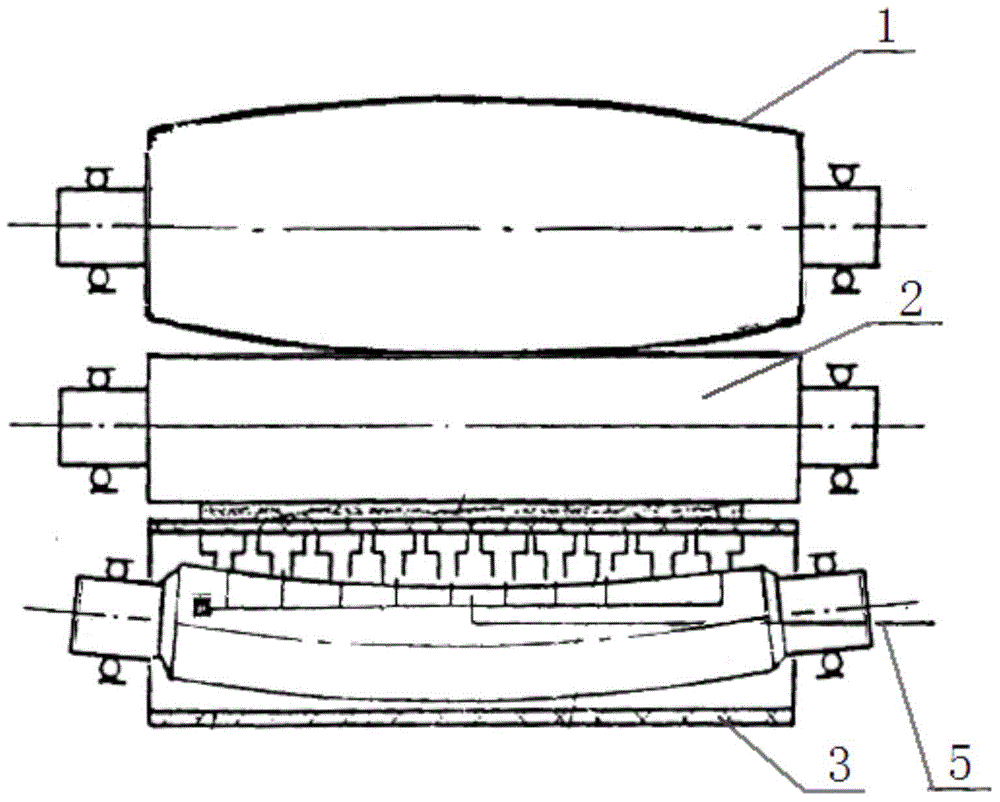

[0027] Such as figure 1 As shown, the upper roller 1 is installed on the top of the frame. The upper roller 1 is spindle-shaped, with a diameter of 500mm, and the maximum amount of deformation in the middle is 50 wires (that is, the diameter of the middlemost is 500.50mm, and the diameter of the two ends is 500mm). The upper end of the frame cannot move, but can rotate around its own axis. Upper roll 1 is made up of roll shaft and roll body, and the material of roll shaft is No. 48 carbon steel, diameter 360mm. The roller body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com