Yeast extract and method for preparing same

A technology of yeast extract and yeast milk, which is applied in the field of yeast extract and its preparation, can solve problems such as poor fluidity of yeast extract, and achieve the effect of bright color, moderate viscosity, and guaranteed physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

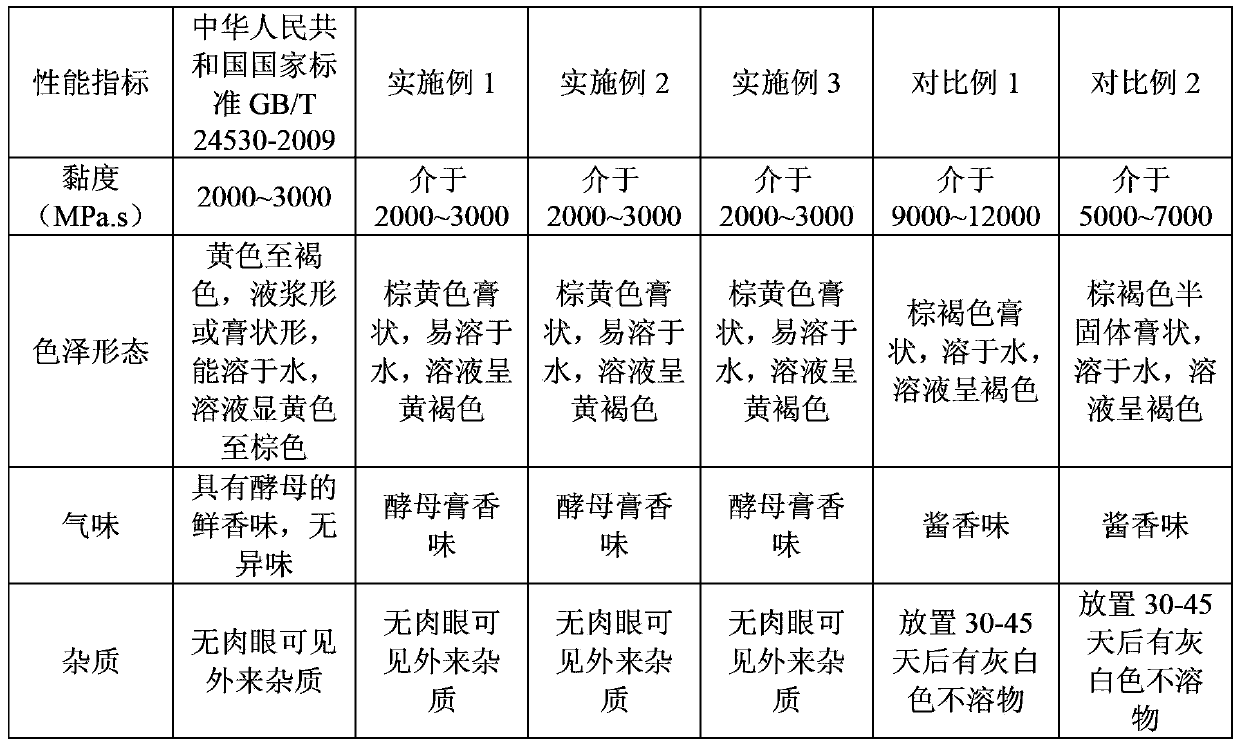

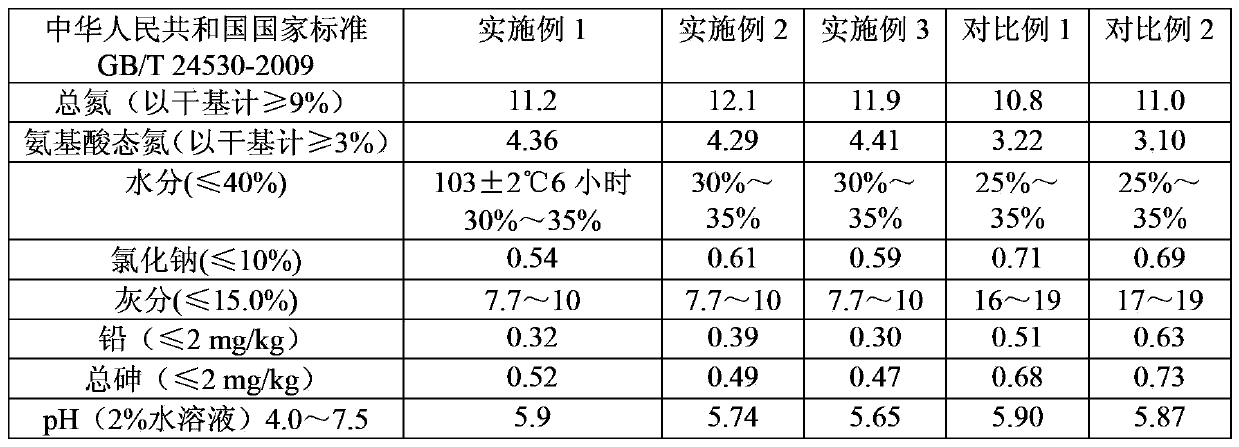

Examples

Embodiment 1

[0044] Take 1L of baker's yeast fermentation broth with a protein content of 50%, wash with filtered water and centrifuge three times to obtain yeast milk with a product color that meets the requirements. Add filtered water and citric acid to the yeast milk at 8°C to prepare a yeast milk suspension with a pH value of 3.6 and a yeast dry matter mass ratio concentration of 10%.

[0045] Add 20ml of ethyl acetate to the yeast milk suspension, raise the temperature to 40°C and adjust the pH value to 4, after autolysis for 5 hours, raise the temperature of the yeast milk suspension to 50°C, adjust the pH value to 6 with citric acid, add papain to make The mass concentration of papain in the yeast milk suspension is 0.01%, and the enzymolysis is carried out for 10 hours to obtain the enzymolysis solution. The enzymolysis solution was heated to 70°C to terminate the enzymolysis, and then placed in a centrifuge at 4000r / min for 10 minutes to obtain the leaching supernatant.

[0046] ...

Embodiment 2

[0048] Take 1L of baker's yeast fermentation broth with a protein weight content of 60%, wash with filtered water and centrifuge three times to obtain yeast milk with a product color that meets the requirements. At 12°C, the yeast milk was formulated with filtered water and acetic acid to obtain a yeast milk suspension with a pH value of 4.2 and a yeast dry matter concentration of 15%.

[0049] Add 15ml of glyceryl monostearate to the yeast milk suspension, raise the temperature to 60°C and adjust the pH value to 6, after 8 hours of autolysis, raise the temperature of the yeast milk suspension to 60°C and adjust the pH value to 8 with acetic acid, add flavor The mass percent concentration of protease is 0.03%, and the enzymolysis is carried out for 15 hours to obtain an enzymolysis solution. The enzymolysis solution was heated to 90°C to terminate the enzymolysis, and then placed in a centrifuge at 5000r / min for 20 minutes to obtain a leaching supernatant.

[0050] The leachi...

Embodiment 3

[0052] Take 1L of baker's yeast fermentation broth with a protein weight content of 60%, wash with filtered water and centrifuge three times to obtain yeast milk with a product color that meets the requirements. At 12°C, the yeast milk was formulated with filtered water and acetic acid to obtain a yeast milk suspension with a pH value of 4.2 and a yeast dry matter concentration of 15%.

[0053] Add 15ml of glyceryl monostearate to the yeast milk suspension, raise the temperature to 60°C and adjust the pH value to 6, after autolysis for 8 hours, raise the temperature of the yeast milk suspension to 60°C and adjust the pH value to 8 with acetic acid, add flavor The mass percent concentration of protease is 0.03%, and the enzymolysis is carried out for 15 hours to obtain an enzymolysis solution. The enzymolysis solution was heated to 90°C to terminate the enzymolysis, and then placed in a centrifuge at 5000r / min for 20 minutes to obtain a leaching supernatant.

[0054] The leach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com