Method for producing base oil from synthetic gas

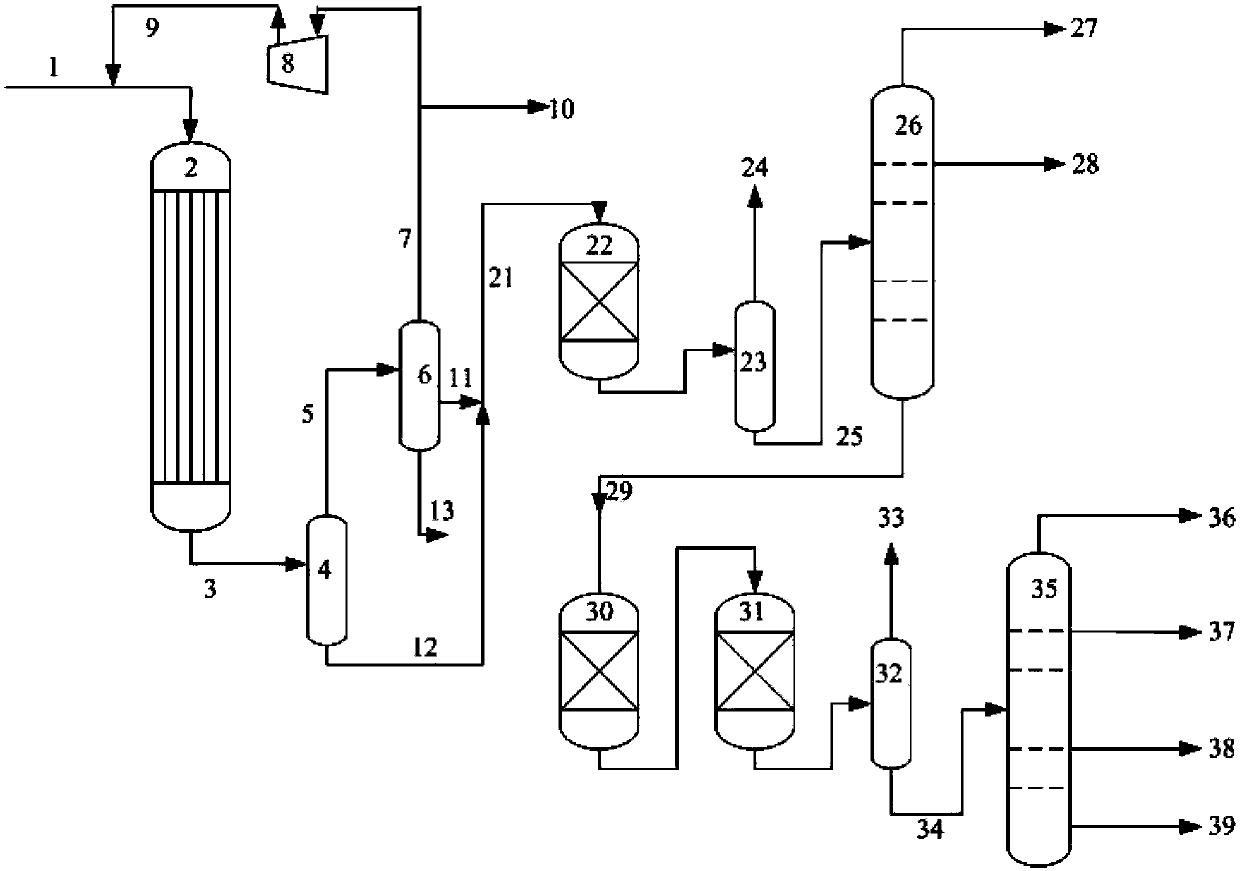

A technology for base oil and synthesis gas, which is applied in the field of diesel oil and lubricating oil base oil, hydrocarbons obtained by Fischer-Tropsch synthesis, and naphtha production. rate increases, lower capital and operating costs, and improved product composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] The preparation process of the Fischer-Tropsch synthesis catalyst used in the examples is as follows: take aluminum oxide powder, add distilled water dropwise to incipient wetness, record the volume of consumed water, and then calculate according to the Co content (oxide basis) 27% by weight, prepare the Cobalt nitrate impregnation solution. Then impregnate alumina with this solution to incipient wetness, let it stand for 8 hours, then dry it at 120°C for 4 hours, and bake it in a muffle furnace at 450°C for 4 hours to prepare the catalyst. The particle size range of the obtained cobalt-based Fischer-Tropsch synthesis catalyst is 1.2-1.6 mm.

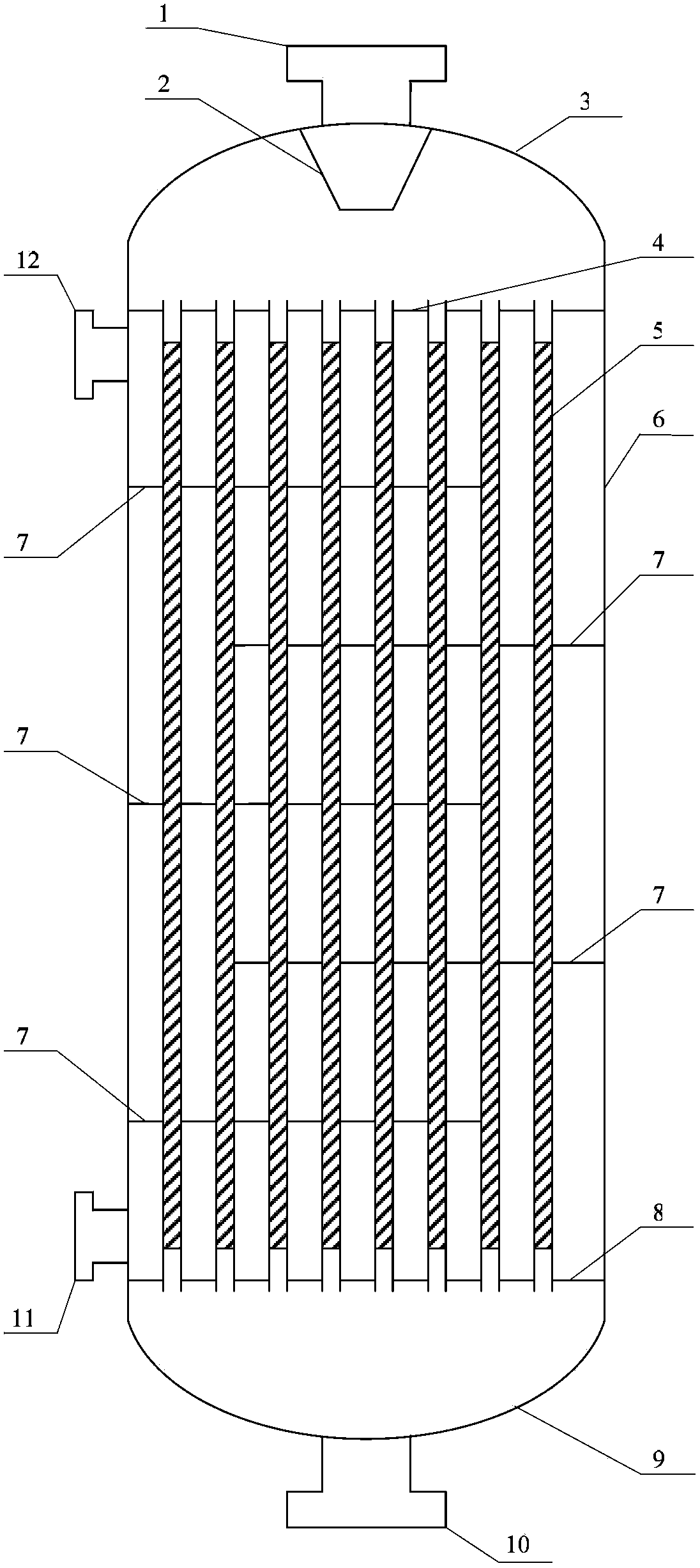

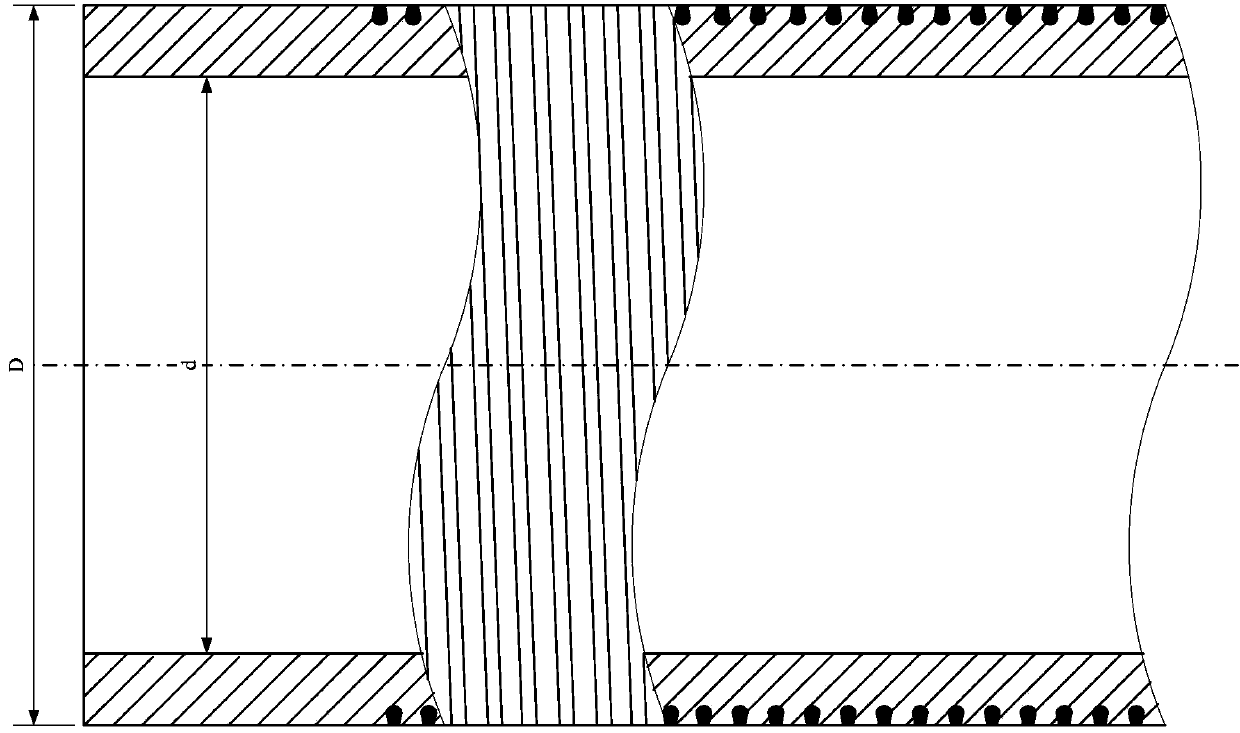

[0055] There are 300 reaction tubes in the Fischer-Tropsch synthesis tubular fixed bed reactor. The reaction tubes are made of austenitic stainless steel pipes with an outer diameter of 38 mm and a wall thickness of 3 mm. The groove has a depth of 1.2mm, an average groove width of 0.6mm, and a helix angle of 4°.

[0056] Fischer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com