Shape memorizing liquid crystal epoxy resin-glass fiber-silicon dioxide composite and preparation method thereof

A silica and glass fiber technology, applied in the field of shape memory liquid crystal epoxy resin-glass fiber-silica composite material and its preparation, can solve the problem of not being able to meet the requirements of cost and performance at the same time, and achieve high shape fixation rate and deformation recovery rate, improving interface adhesion, and the effect of strong interface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

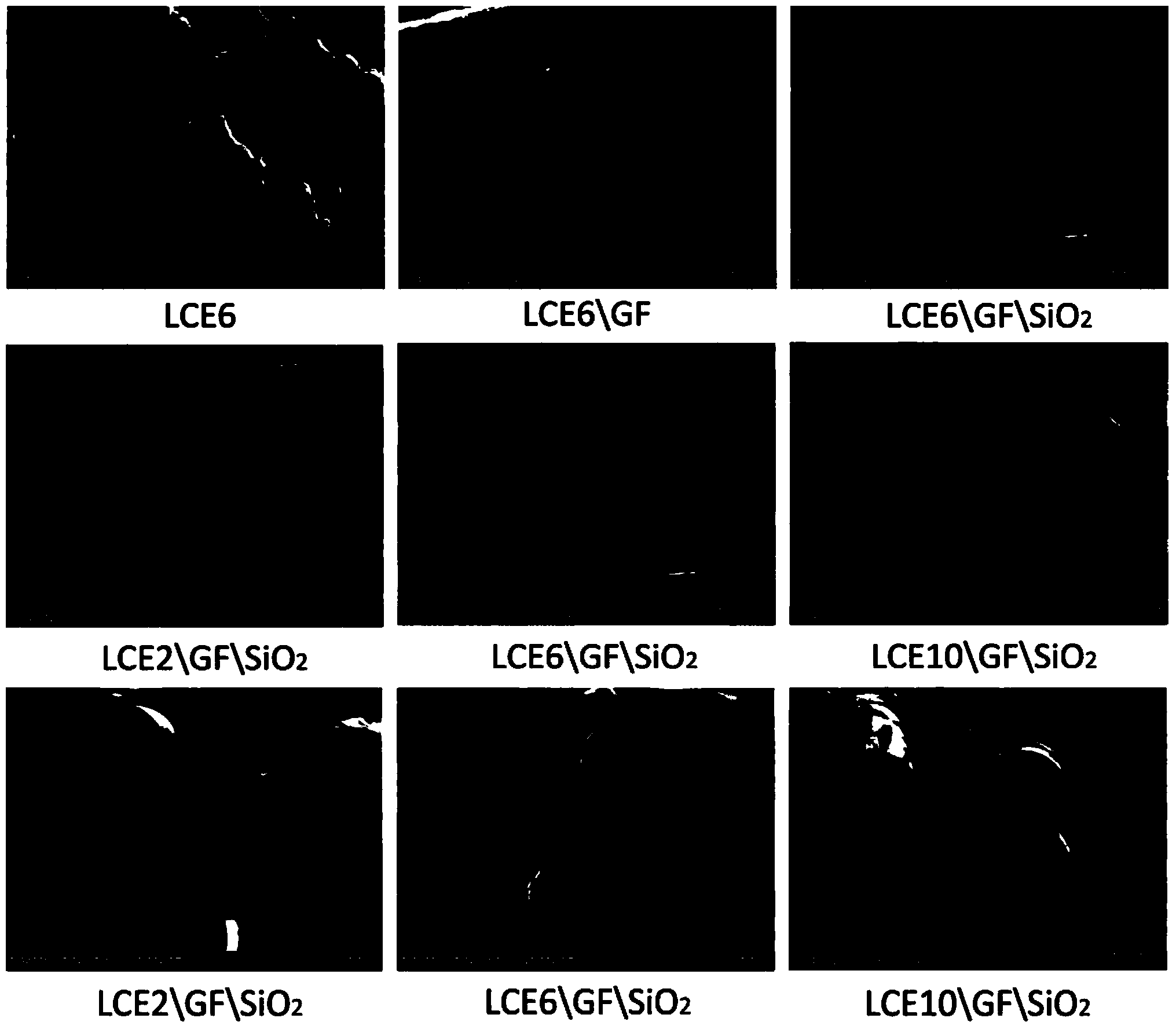

[0038] (1) Silica and glass fiber surface treatment: Take 10g of dried nano-silica with a particle size of 20nm and a purity of 99.9%, and 100ml of anhydrous acetone in a beaker. Under ultrasonic conditions, gradually add 1g of silane The acetone solution of the coupling agent KH570, after ultrasonication for 30 minutes, suction filtration, drying in a vacuum oven to obtain surface-treated silica; the thickness is 0.1mm, and the gram weight is 300g / m 2 Soak and wash the alkali-free glass fiber cloth in acetone solution for 24 hours, take it out and dry it at room temperature to obtain the glass fiber after surface treatment;

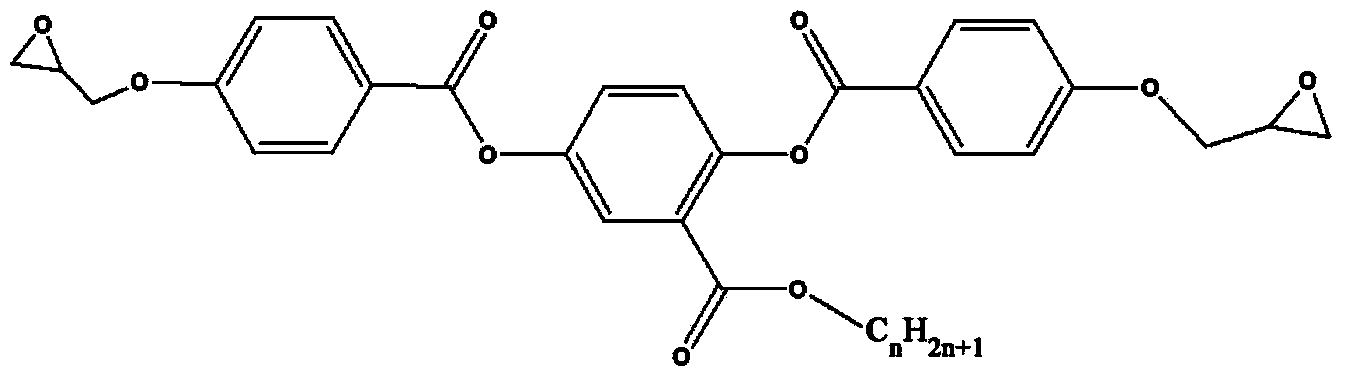

[0039] (2) Preparation of composite material mixed solution: take liquid crystal epoxy resin 5.81g and curing agent DDM0.98g shown in formula 2 with a molar ratio of 2:1, dissolve in 20ml acetone to obtain mixed solution, and then add step ( 1) 0.21 g of treated nano-silica, ultrasonically vibrated for 30 minutes, so that the silicon dioxide is uniformly...

Embodiment 3

[0045] (1) Silica and glass fiber surface treatment: Take 10g of dried nano-silica with a particle size of 20nm and a purity of 99.9%, and 100ml of anhydrous acetone in a beaker. Under ultrasonic conditions, gradually add 1g of silane The acetone solution of the coupling agent KH570, after ultrasonication for 30 minutes, suction filtration, drying in a vacuum oven to obtain surface-treated silica; the thickness is 0.1mm, and the gram weight is 300g / m 2 Soak and wash the alkali-free glass fiber cloth in acetone solution for 24 hours, take it out and dry it at room temperature to obtain the glass fiber after surface treatment;

[0046] (2) Preparation of composite material mixed solution: take liquid crystal epoxy resin 5.73g and curing agent DDM1.06g shown in formula 3 with a molar ratio of 2:1, dissolve in 20ml acetone to obtain mixed solution, then add step ( 1) 0.21 g of treated nano-silica, ultrasonically vibrated for 30 minutes, so that the silicon dioxide is uniformly dis...

Embodiment 4

[0052] (1) Silica and glass fiber surface treatment: Take 10g of dried nano-silica with a particle size of 20nm and a purity of 99.9%, and 100ml of anhydrous acetone in a beaker. Under ultrasonic conditions, gradually add 1g of silane The acetone solution of the coupling agent KH570, after ultrasonication for 30 minutes, suction filtration, drying in a vacuum oven to obtain surface-treated silica; the thickness is 0.1mm, and the gram weight is 300g / m 2 Soak and wash the alkali-free glass fiber cloth in acetone solution for 24 hours, take it out and dry it at room temperature to obtain the glass fiber after surface treatment;

[0053] (2) Composite material mixed solution preparation: take by weighing liquid crystal epoxy resin 5.89g and curing agent DDM0.9g shown in formula 4 that molar ratio is 2:1, dissolve in 20ml acetone, obtain mixed solution, then add step ( 1) 0.21 g of treated nano-silica, ultrasonically vibrated for 30 minutes, so that the silicon dioxide is uniformly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com