A kind of rare earth sulfide rubber additive and preparation method thereof

A rare earth sulfide and rubber technology, which is applied in the field of rare earth sulfide rubber additives and its preparation, can solve the problems of unfavorable environmental protection, etc., and achieve the effects of easy operation, low production cost and energy consumption, and prevention of aging and degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

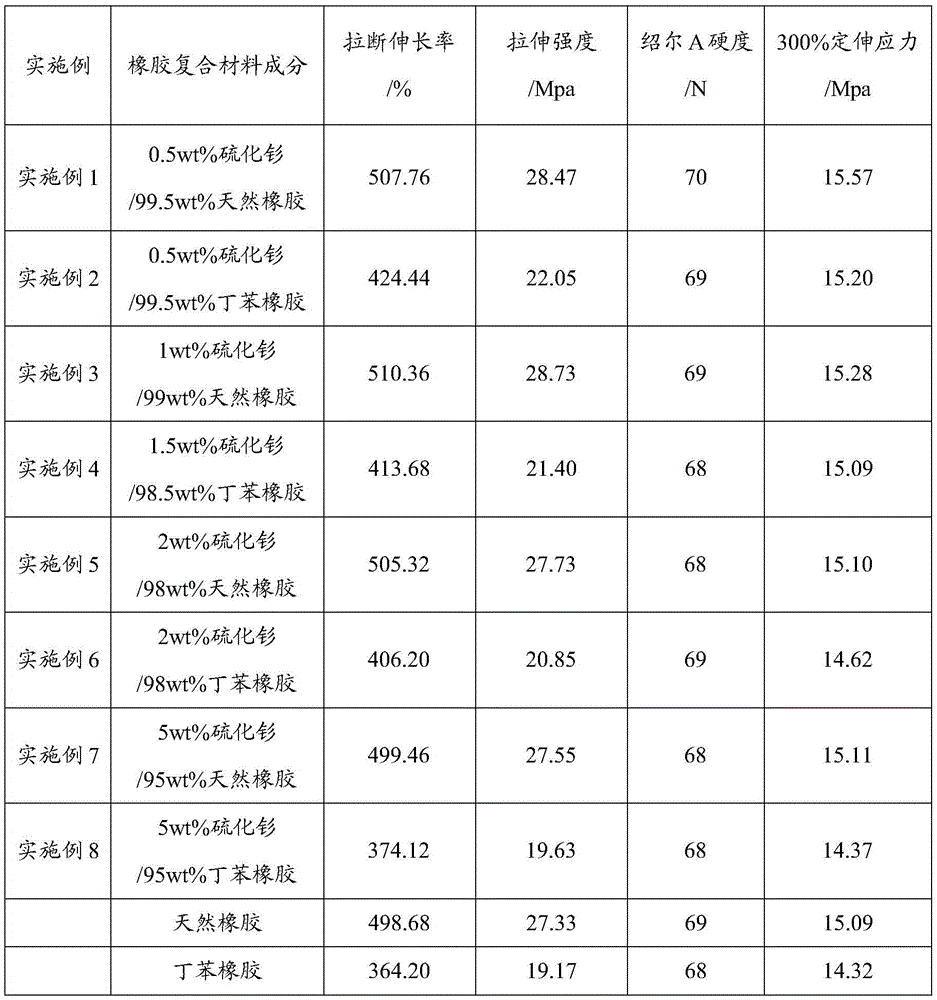

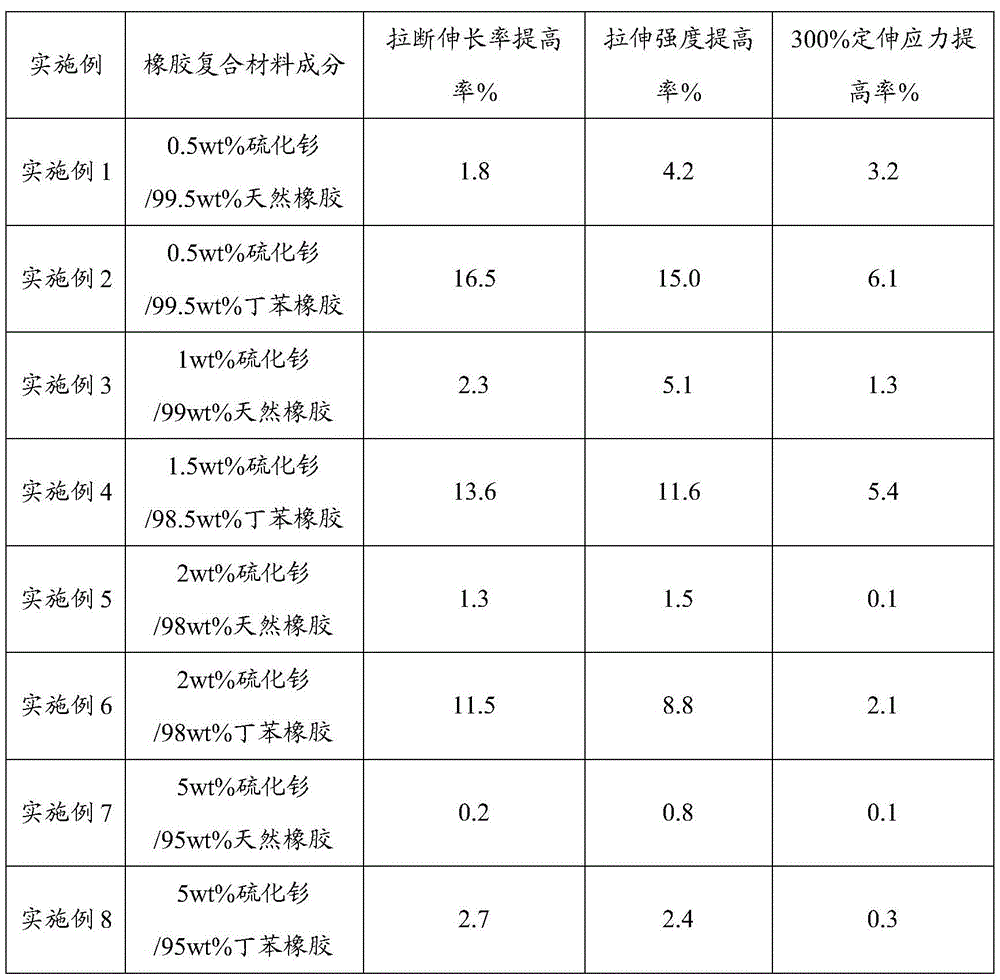

Embodiment 1

[0024] Example 1 Preparation of rubber composites

[0025] Mix 0.5wt% rare earth samarium sulfide with 99.5wt% natural rubber, and masticate at 50-60°C for 24 hours, then knead for 30min at the temperature of the front roll at 55-60°C and at the temperature of the rear roll at 50-55°C, and then in At 140-150°C, vulcanize for 2 hours to obtain rubber composite materials.

Embodiment 2

[0026] Example 2 Preparation of rubber composites

[0027] Mix 0.5wt% rare earth samarium sulfide with 99.5wt% styrene-butadiene rubber, masticate at 30-45°C for 3 hours, then knead for 45min at the temperature of the front roll at 45-55°C and at the temperature of the rear roll at 50-60°C, and then At 150-160°C, vulcanize and mold for 2 hours to obtain rubber composite materials.

Embodiment 3

[0028] Example 3 Preparation of rubber composites

[0029] Mix 1wt% rare earth samarium sulfide with 99wt% natural rubber, and masticate at 50-60°C for 24 hours, then knead at the temperature of the front roll at 55-60°C and the temperature of the rear roll at 50-55°C for 30 minutes, and then at 140-60°C At 150°C, vulcanize for 2 hours to obtain a rubber composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com