Method for preparing high molecular weight vertical structure composite polylactic acid with melt stability characteristics

A high-molecular-weight, composite technology, applied in the field of high-molecular-weight stereocomplex polylactic acid, can solve the problems of a large number of toxic reagents, low production efficiency, long time consumption, etc., and achieve the effect of excellent melt stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

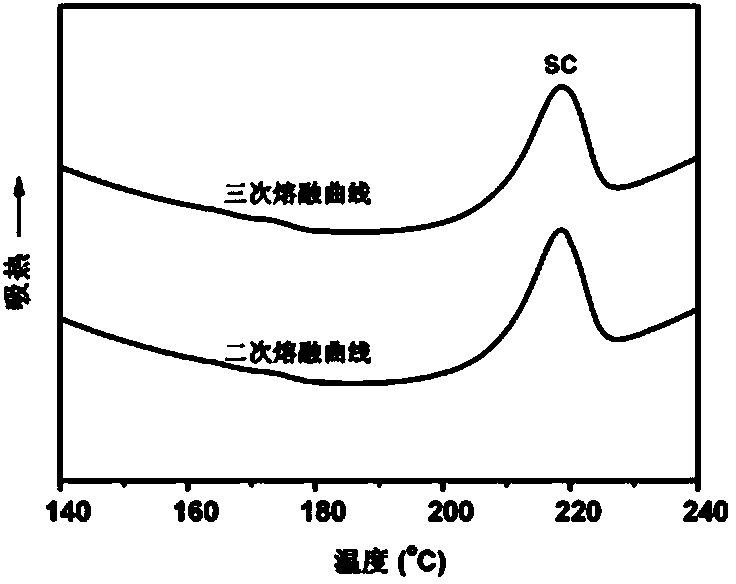

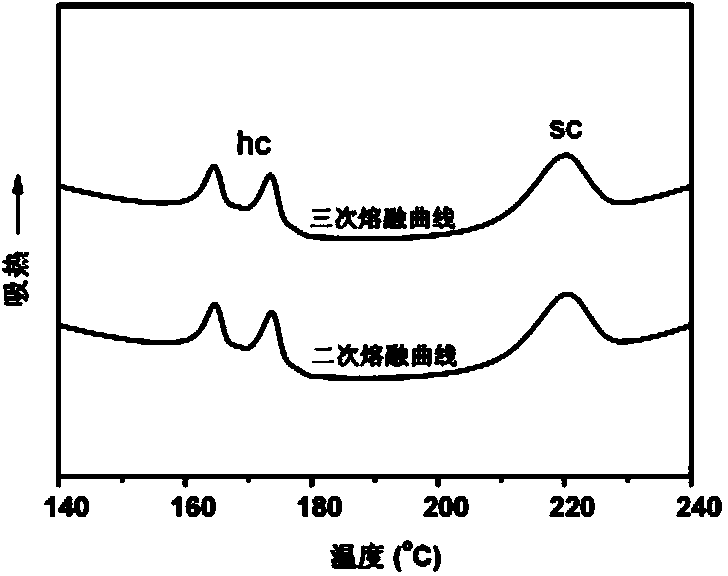

[0032] The weight average molecular weight was 1×10 4 g·mol and 5×10 5 PLLA and PDLA with g mol and optical purity of 92% and 99.5% respectively were vacuum-dried at 50°C until the moisture content was lower than 200ppm under a vacuum degree of less than 900Pa; Completely dissolve in absolute ethanol, then stir and mix it with 60 parts of PLLA and 40 parts of PDLA; put the mixed material into the melting mixer of the torque rheometer, and melt at a temperature of 200 ° C and a rotor speed of 120 rpm Blend for 2 minutes to obtain powdered sc-PLA.

Embodiment 2

[0034] The weight average molecular weight was 2.1×10 5 g·mol and 1.2×10 5 PLLA and PDLA with g mol and optical purity of 98.5% and 99.5% respectively were vacuum-dried at 60°C until the moisture content was lower than 200ppm under a vacuum degree of less than 900Pa; Completely dissolve in absolute ethanol, then stir and mix it with 50 parts of PLLA and 50 parts of PDLA; put the mixed material into the melting mixer of the torque rheometer, and melt at a temperature of 180 ° C and a rotor speed of 60 rpm Blend for 5 minutes to obtain powdered sc-PLA.

Embodiment 3

[0036] The weight average molecular weight was 2.1×10 5 g·mol and 1.2×10 5PLLA and PDLA with g mol and optical purity of 98.5% and 99.5% respectively were vacuum-dried at 60°C until the moisture content was lower than 200ppm under a vacuum degree of less than 900Pa; Completely dissolve in absolute ethanol, then stir and mix it with 50 parts of PLLA and 50 parts of PDLA; put the mixed material into the melting mixer of the torque rheometer, and melt at a temperature of 180 ° C and a rotor speed of 50 rpm After blending for 7 minutes, powdered sc-PLA was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com