Biofilm electrode and uasb coupled reactor

A biomembrane electrode and reactor technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of lack of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

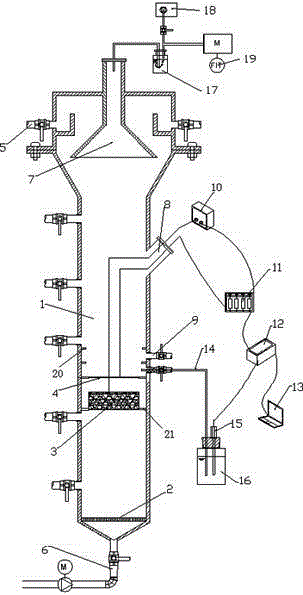

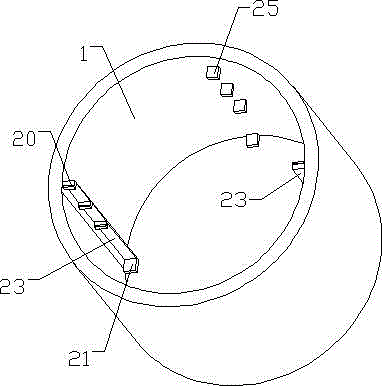

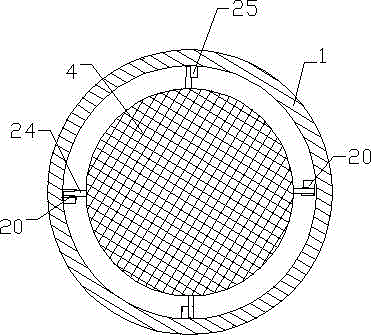

[0023] The specific embodiment of the present invention will be described with reference to the accompanying drawings. Such as figure 1 As shown, the biofilm electrode is coupled with the UASB reactor, including a reactor cylinder 1, a biofilm electrode system, an electrochemical test system and a cathode potential test device;

[0024] There is a water inlet 6 at the bottom of the reactor cylinder 1, and a water outlet 5 and a three-phase separator 7 at the top. The reactor cylinder 1 includes a water distribution plate 2 and a biofilm electrode system from bottom to top; the sludge bed area is between the biofilm electrode system and the three-phase separator 7;

[0025] The outlet 5 is formed by an overflow weir, and the outlet channel is connected with the outlet pipe of the reactor cylinder 1.

[0026] The gas-collecting hood of the three-phase separator 7 is connected to the water-sealed bottle 17 and the wet gas flow meter 19 successively through the gas pipeline, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com