Preparation method of slow-release carbon source filter material taking starch and polyvinyl alcohol as substrates

A polyvinyl alcohol and slow-release carbon source technology, which is applied in the field of water treatment, can solve problems such as excess and insufficient carbon sources, and achieve the effect of prolonging the service life and weakening the carbon release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

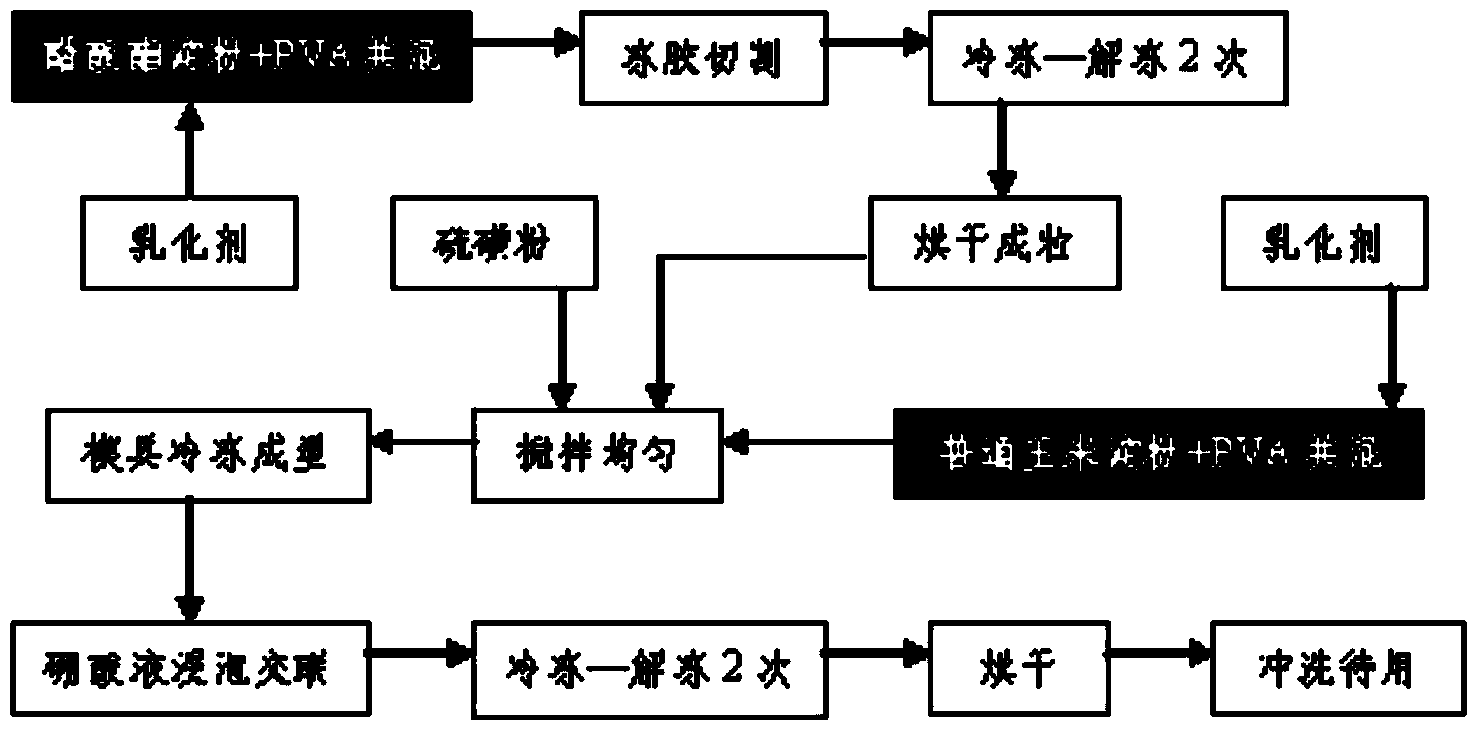

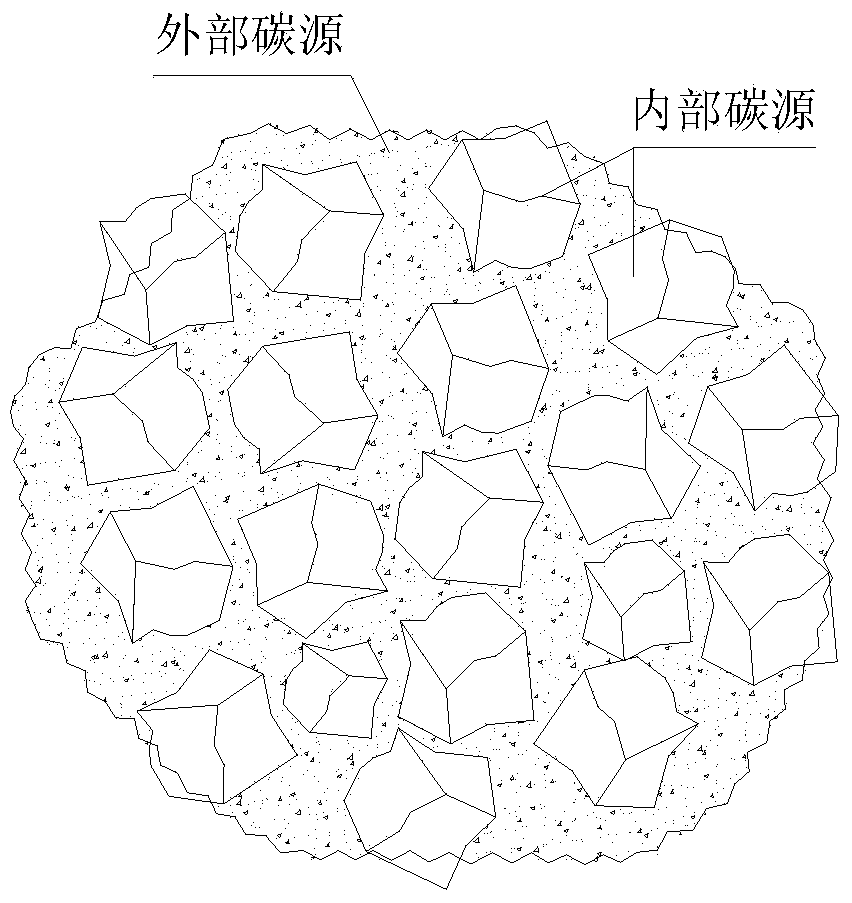

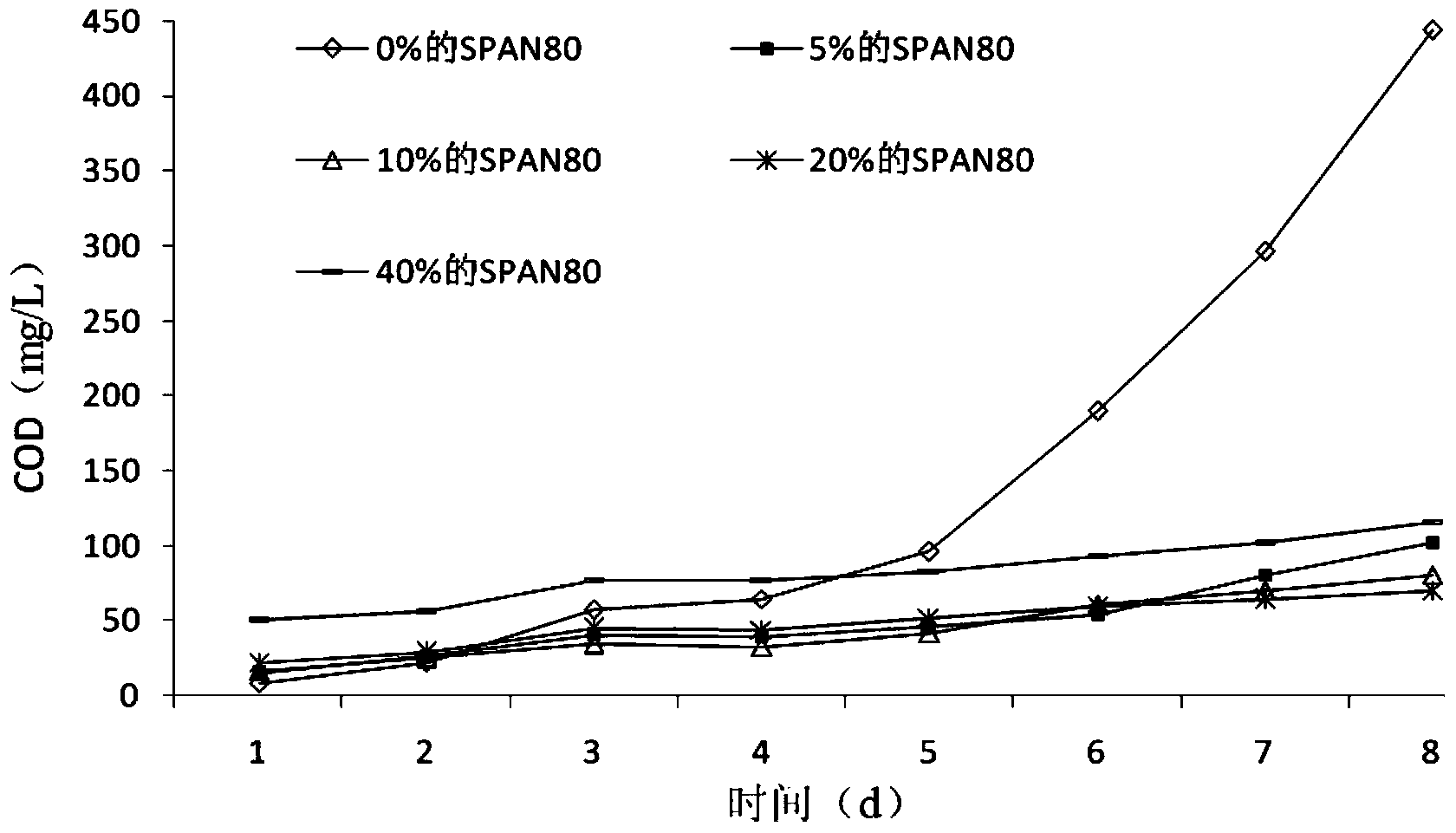

[0049] Production of slow-release carbon source filter material:

[0050] In the internal carbon source, according to the ratio of starch acetate:PVA=1:1, weigh 10g and 10g respectively, put them into a beaker, and add 80mL of water and 1mL of SPAN80. Put the beaker in a water bath at 100°C, and stir the mixture in the cup until it is evenly blended and becomes a paste with a uniform texture. Pour the pasty liquid into a flat plate mold with a shallow groove, spread it flat, put it in a -7°C refrigerator and freeze it into blocks, and then thaw it at room temperature after freezing to form a jelly, and cut the jelly into 1-2cm 3 The pellets are then subjected to two "freezing-thawing" processes. Dry in an oven at 85°C to form a 0.3-0.5cm 3 The size of the pellets, ready to use.

[0051] In the external carbon source, according to the ratio of ordinary cornstarch:PVA=1:2, weigh 2g and 4g respectively, put them into a beaker, and add 34mL of water and 0.3mL of SPAN80. Put th...

Embodiment 2

[0058] Production of slow-release carbon source filter material:

[0059] In the internal carbon source, according to the ratio of starch acetate:PVA=2:1, weigh 10g and 5g respectively, put them into a beaker, and add 60mL of water and 0.75mL of SPAN80. Put the beaker in a water bath at 100°C, and stir the mixture in the cup until it is evenly blended and becomes a paste with a uniform texture. Pour the pasty liquid into a flat plate mold with a shallow groove, spread it flat, put it in a -7°C refrigerator and freeze it into blocks, and then thaw it at room temperature after freezing to form a jelly, and cut the jelly into 1-2cm 3 The pellets are then subjected to two "freezing-thawing" processes. Dry in an oven at 85°C to form a 0.3-0.5cm 3 The size of the pellets, ready to use.

[0060] In the external carbon source, according to the ratio of ordinary cornstarch:PVA=1:2, weigh 2g and 4g respectively, put them into a beaker, and add 34mL of water and 0.3mL of SPAN80. Put ...

Embodiment 3

[0067] Production of slow-release carbon source filter material:

[0068] In the internal carbon source, according to the ratio of starch acetate:PVA=3:1, weigh 15g and 5g respectively, put them into a beaker, and add 80mL of water and 1mL of SPAN80. Put the beaker in a water bath at 100°C, and stir the mixture in the cup until it is evenly blended and becomes a paste with a uniform texture. Pour the pasty liquid into a flat plate mold with a shallow groove, spread it flat, put it in a -7°C refrigerator and freeze it into blocks, and then thaw it at room temperature after freezing to form a jelly, and cut the jelly into 1-2cm 3 The pellets are then subjected to two "freezing-thawing" processes. Dry in an oven at 85°C to form a 0.3-0.5cm 3 The size of the pellets, ready to use.

[0069] In the external carbon source, according to the ratio of ordinary cornstarch:PVA=1:2, weigh 2g and 4g respectively, put them into a beaker, and add 34mL of water and 0.3mL of SPAN80. Put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com