An aluminum alloy product with a fluororesin coating

A technology of fluororesin coating and aluminum alloy products, which is applied in the field of aluminum alloy product manufacturing, can solve the problems of shortened product life, deterioration of non-stick effect, and impact on product surface aesthetics, etc., to achieve improved service life, good non-stick and durability scratchy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

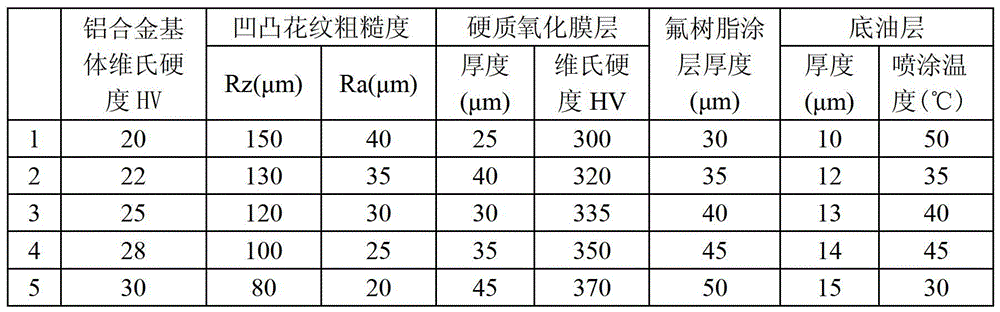

[0014] The invention provides an aluminum alloy product with a fluororesin coating, which comprises an aluminum alloy substrate with concavo-convex patterns on the surface, a hard oxide film layer and a fluororesin coating sequentially covering the surface of the aluminum alloy substrate. Its specific manufacturing process is as follows:

[0015] (1) Form irregular concave-convex patterns with a roughness within a preset range and a radian at the top of the convex part on the surface of a soft aluminum alloy substrate.

[0016] The aluminum alloy matrix used in the present invention is a relatively soft aluminum alloy plate, and its Vickers hardness HV is 20-30, preferably 22-28. Micro-deformation or side-to-side movement due to high pressure, so it will not be worn out immediately. The surface of the aluminum alloy substrate used in the present invention has an irregular concave-convex pattern, and the pattern is specifically as follows figure 1 As shown, the top 1 of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com