Method for manufacturing vacuum brazing cooler

A manufacturing method and radiator technology are applied in the field of vacuum brazing aluminum or aluminum alloy radiators, which can solve the problems of high cost of aluminum-clad welding rods, high raw material costs, unsuitability for radiators, etc. The effect of low cost and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The production process of a company's photovoltaic inverter vacuum brazing radiator.

[0032] (1) Melting and casting refining: put aluminum ingots into the melting furnace for smelting, and use online degassing to remove low-melting point light metals and non-metallic impurities, and use 1060 grade aluminum alloy to cast rods;

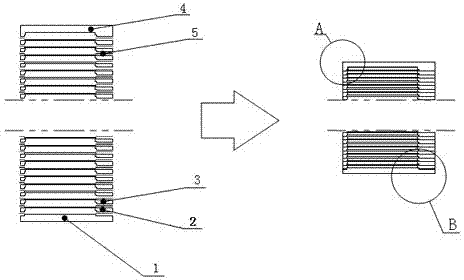

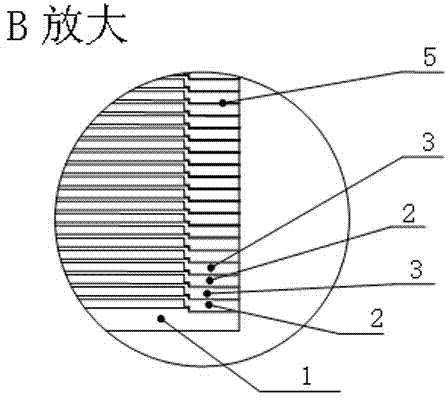

[0033] (2) Extrusion: the blades are extruded profiles, and the whole radiator is composed of three extruded profiles;

[0034] (3) Sawing: cutting the extruded profile into a certain length of aluminum substrate;

[0035] (4) Machining: The sawn aluminum base material is sequentially processed by shaping, stamping and other machining, and used as the blade of the radiator;

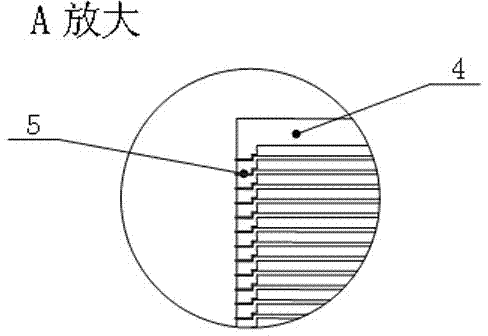

[0036] (5) Lamination: The processed aluminum blades are laminated and assembled, and the two ends of the aluminum blades are embedded with brazing material (brazing film) and then clamped with clamps;

[0037] (6) Vacuum brazing: Vacuum brazing of the workpiece clamped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com