Front frame positioner

A technology of positioner and front frame, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of repeated welding of weld seams, repeated welding of weld seams, and unstable rotation of motors, etc., to achieve The effect of reducing end jump and eccentricity, improving welding quality and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

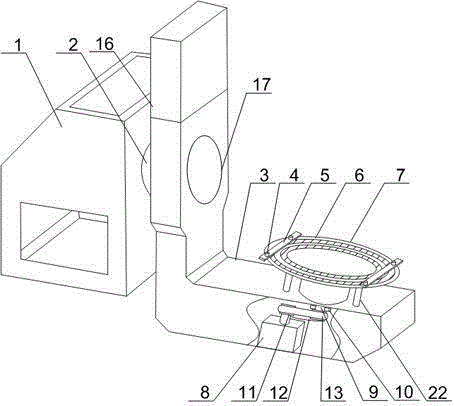

[0023] Such as Figure 1 to Figure 3 As shown, the front frame positioner of the present invention includes a mounting base 1, a motor 2 and an L-shaped support arm 3 are arranged inside the mounting base 1, and a through hole is opened on the vertical part of the L-shaped support arm 3. The output shaft of the motor 2 passes through the through hole and is connected with the L-shaped support arm 3. A DC motor 8 is fixedly installed on the horizontal portion of the L-shaped support arm 3. The output end of the DC motor 8 is connected with a turntable 7. On the turntable 7 is provided with a plurality of internal thread grooves 6, the internal thread groove 6 is an annular body composed of a plurality of adjacent through holes, the internal thread groove 6 radially radiates along the center of the turntable 7; it also includes a pressure plate 5, the The pressure plate 5 is connected to the internal thread groove 6 through the bolt 4, and a shock absorbing structure 17 is arran...

Embodiment 2

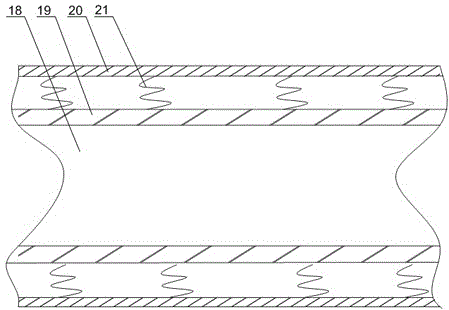

[0025] Such as figure 1 with image 3 As shown, this embodiment is based on Embodiment 1, the shock absorbing structure 17 includes a sleeve 20, a bearing 19 is installed in the sleeve 20, and a plurality of springs are installed between the outer wall of the bearing 19 and the inner wall of the sleeve 20 21, and the spring 21 is in a compressed state. The output end 18 of the motor passes through the bearing 19 to ensure that the L-shaped support arm 3 can freely rotate 360 degrees in the vertical direction. A plurality of springs 21 are installed between the outer wall of the bearing 19 and the inner wall of the sleeve 20, and the springs 21 are always in a compressed state. When the output terminal 18 of the motor runs out radially, the elastic force generated by the spring 21 is opposite to the direction of the radial stress, which can offset the radial stress. Also comprise rotating shaft 9, one end of described rotating shaft 9 is connected with rotating disk 7 botto...

Embodiment 3

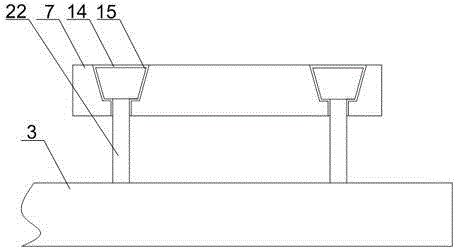

[0027] Such as figure 1 with figure 2As shown, in this embodiment, on the basis of Embodiment 1, an annular trapezoidal groove 14 is provided at the bottom of the turntable 7, a support rod 22 is installed on the horizontal part of the L-shaped support arm 3, and the end of the support rod 22 A protrusion 15 is fixedly connected, and the protrusion 15 engages with the annular trapezoidal groove 14; a balance weight 16 is installed on the upper end of the vertical part of the L-shaped support arm 3 . The bottom of the rotating disk 7 is provided with an annular trapezoidal groove 14, and the protrusion 15 on the support rod 22 is engaged with the annular trapezoidal groove 14. When the L-shaped support arm 3 rotates in the vertical direction, the front frame of the car is inverted, and the front frame itself The gravity will pull the output shaft of the motor 2, which not only increases the operating load of the motor 2, but also causes some damage to the motor 2. The support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com