Bone paste machine

A bone mud machine and casing technology, which is applied in application, food preparation, grain processing, etc., can solve the problems of low production efficiency of the bone mud machine, no adjustment gap, difficulty in manufacturing large threads, etc., so as to improve the cutting quality, The gap adjustment is reliable and convenient, and the effect of reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

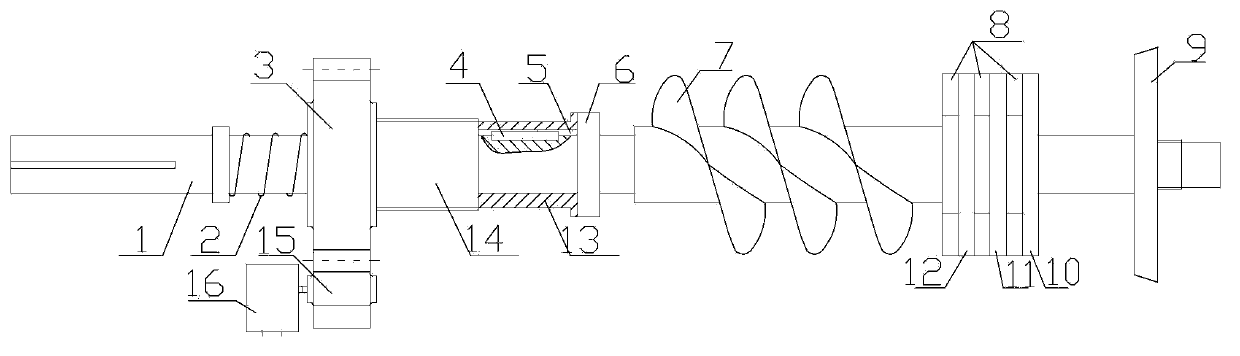

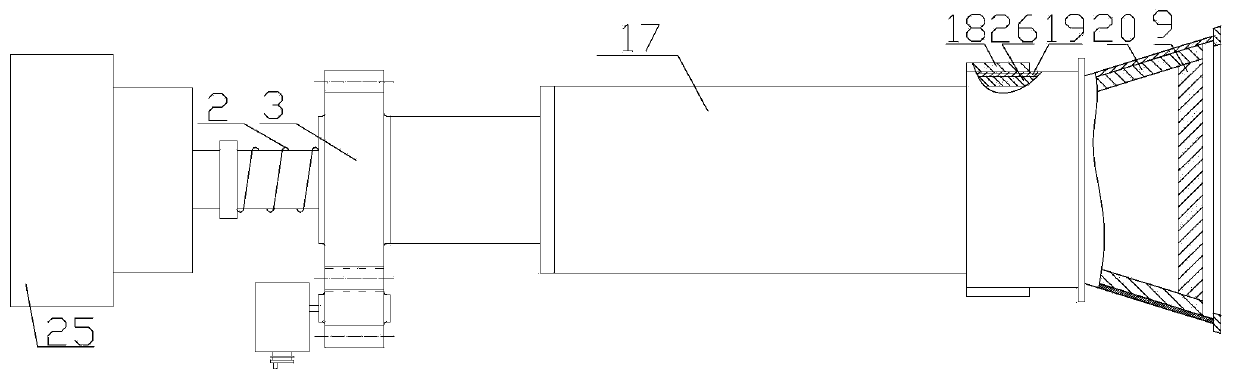

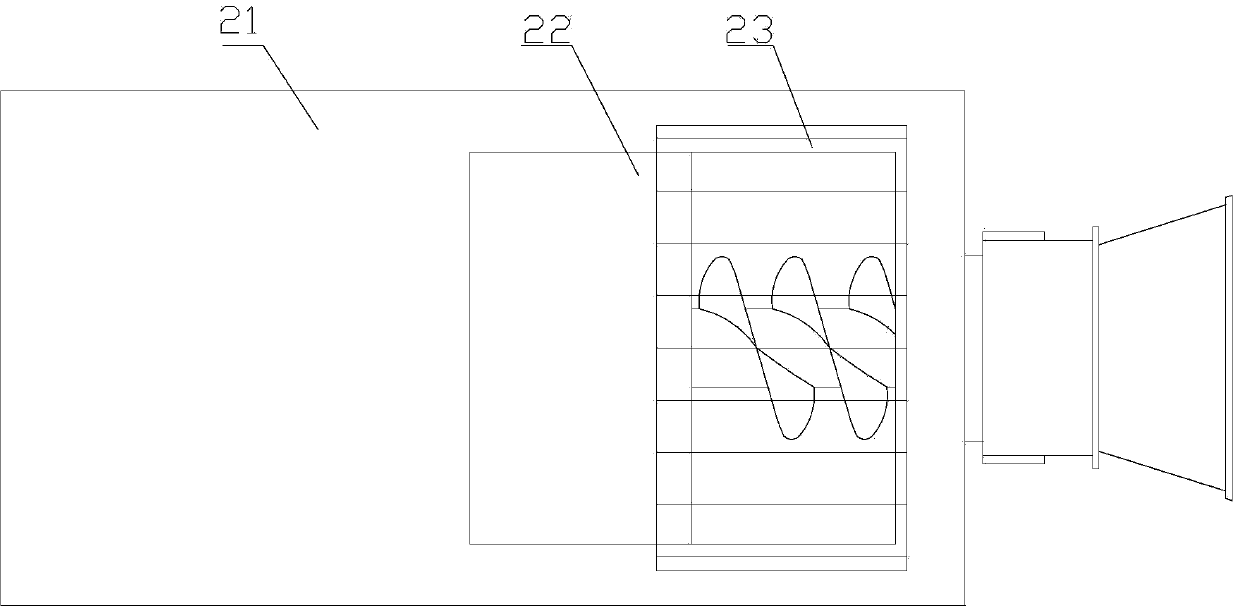

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] As shown in the figure, the bone clay machine includes a rotating shaft 1, a casing 21, a gap adjusting device, a mincing device and a grinding head, and the grinding head includes a moving grinding head 9 and a fixed grinding head 20, wherein the gap adjusting device is arranged on the casing 21 on the inner shaft. One end of rotating shaft 1 is fixed with axle sleeve 25, and axle sleeve 25 is connected with the output end of motor 24 by belt or chain, is connected by key between rotating shaft 1 and axle sleeve 25, and after motor 24 starts, through motor 24 and axle sleeve 25 Between the belt drive or chain drive, the shaft sleeve 25 drives the rotating shaft 1 to rotate. A gap adjusting device is provided on the side of the rotating shaft 1 close to the shaft sleeve 25 . The other end of the rotating shaft 1 is fixed with a movable grinding head 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com