Cracking catalyst capable of increasing octane number of catalytic cracking gasoline

A technology for catalytic cracking gasoline and cracking catalyst, which is applied in catalytic cracking, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of low crystallinity, poor retention rate, and lack of improving molecular sieve dispersibility, so as to avoid the formation of molecular sieves. And the effect of coagulation growth, improving exchange and filtration efficiency, and excellent heavy oil conversion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

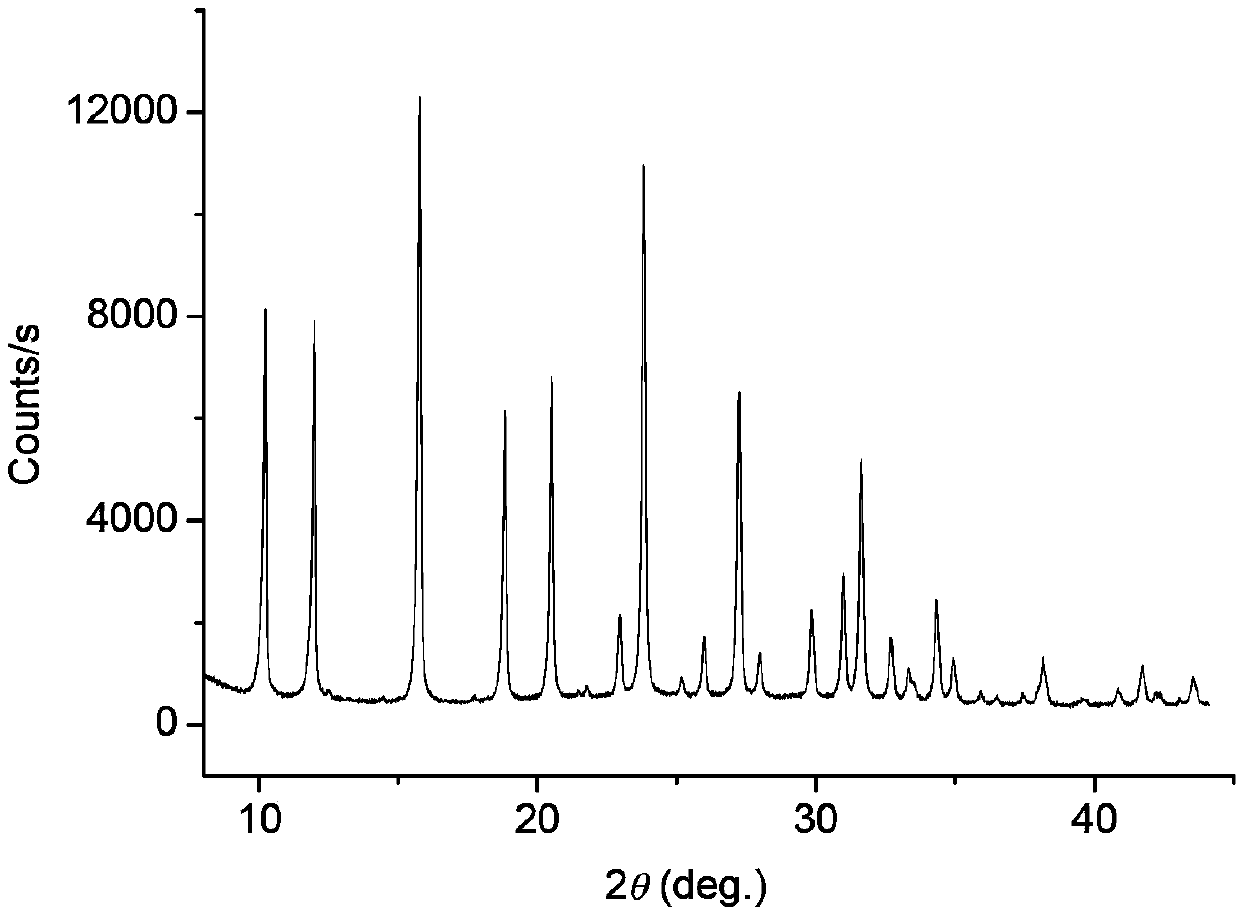

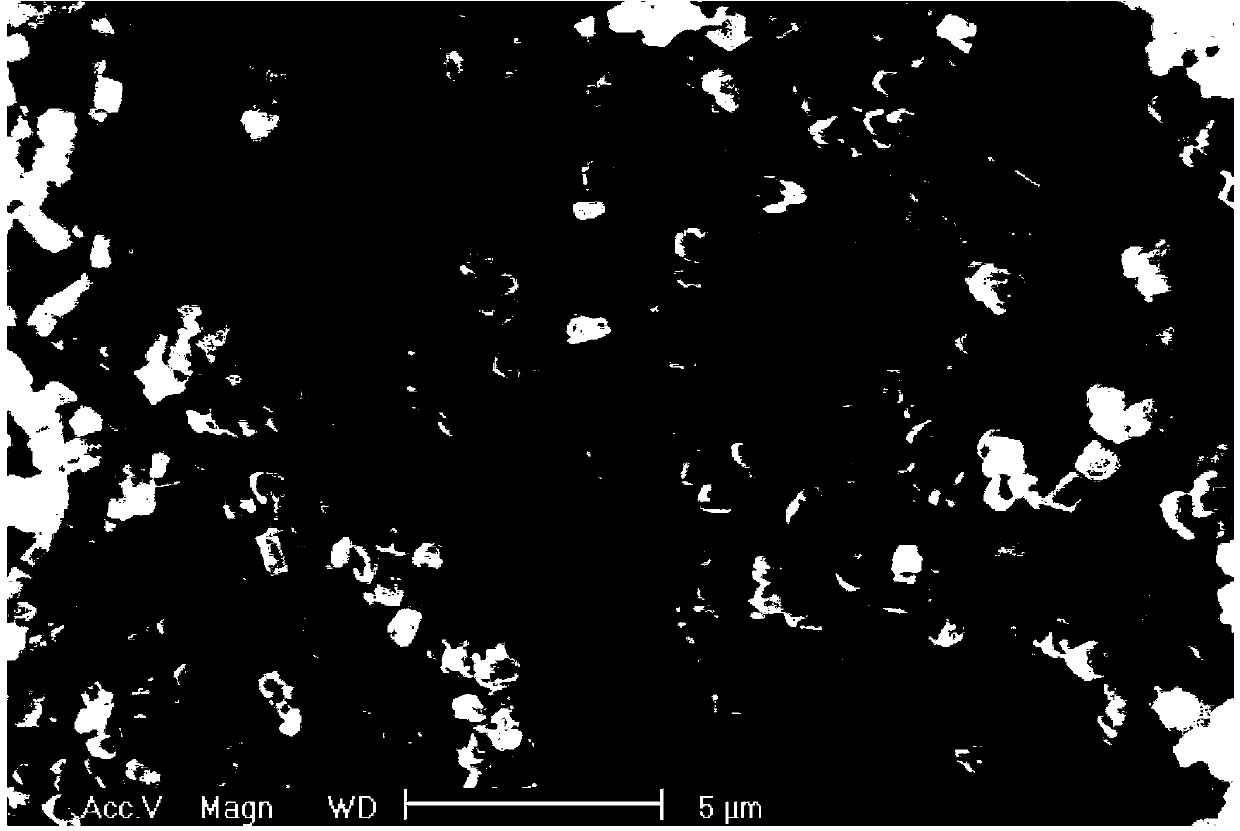

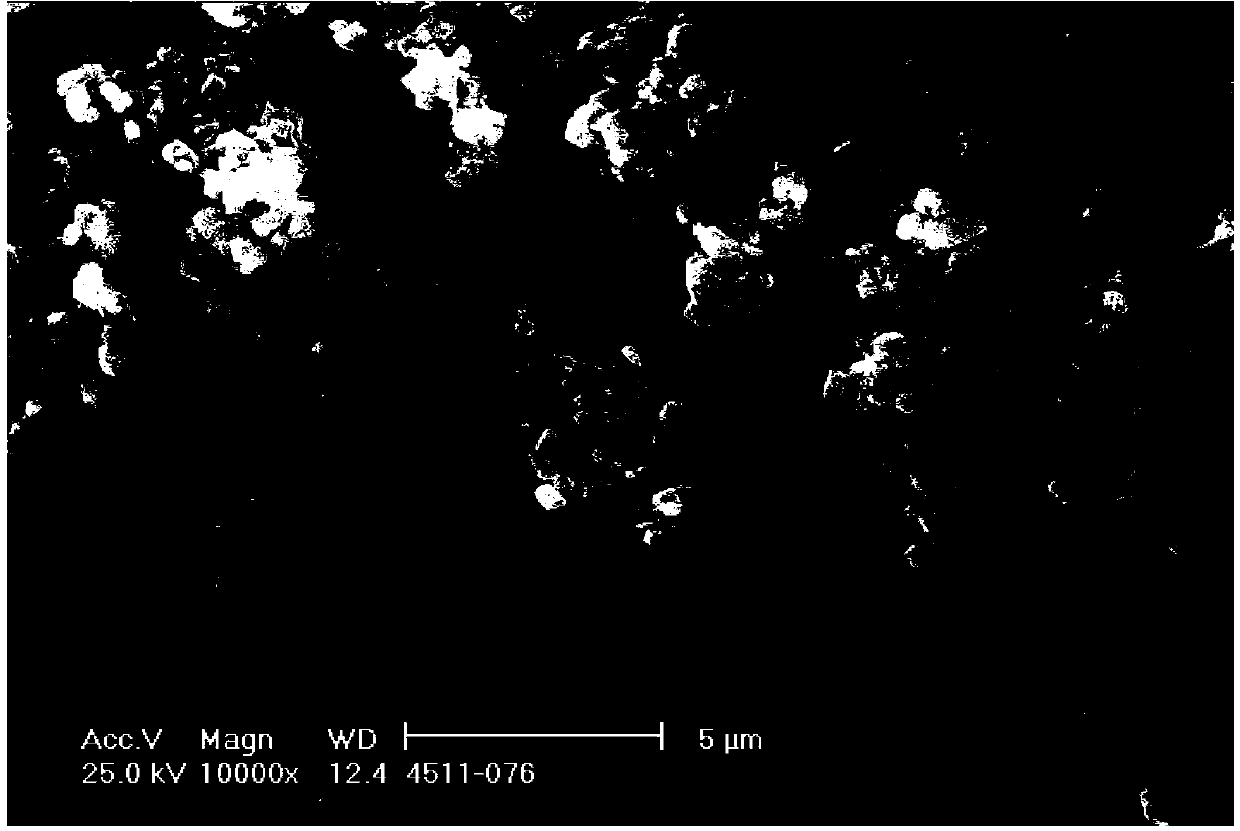

Image

Examples

specific Embodiment approach

[0048] Raw material sources, grades and specifications:

[0049] The NaY molecular sieve crystallization slurry used in comparative examples and examples is synthesized according to the method published in the document Verified Syntheses of Zeolitic Materials, 1st Edition [J], 1998, 22 (46): 604-605, and the solid content of the NaY molecular sieve slurry is 120g / l (The silicon-aluminum ratio of the molecular sieve framework is 4.85, and the unit cell constant is 2.467nm).

[0050] ZSM-5 molecular sieve: obtained from the Catalyst Factory of Lanzhou Petrochemical Company.

[0051] REY: Taken from the Catalyst Factory of Lanzhou Petrochemical Company, the rare earth oxide content is 13~15wt%

[0052] REUSY-1: from the Catalyst Factory of Lanzhou Petrochemical Company, the rare earth content is 7~9wt%

[0053] REUSY-2: from the Catalyst Plant of Lanzhou Petrochemical Company, the rare earth content is 3.5~4.5wt%

Embodiment 1

[0056] Take 500ml of NaY slurry, and maintain the crystallization slurry temperature at 60°C. Filter and separate the molecular sieve crystallization slurry on a simulated belt filter. When the filter cake is not cracked, wash the molecular sieve filter cake with 300ml of 0.02mol / l NaOH solution (50°C) and dry it. Record the sample as N-1.

Embodiment 2

[0058] Take 500ml of NaY slurry, and maintain the crystallization slurry temperature at 60°C. Filter and separate the molecular sieve crystallization slurry on a simulated belt filter. When the filter cake is not cracked, wash the molecular sieve filter cake with 100ml of 0.1mol / l NaOH solution (80°C) and dry it. Record the sample as N-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| unit cell | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com