Catalyst for preparing chlorinated aromatic amine and preparation method thereof

A catalyst and aromatic amine technology, applied in the field of catalysis, can solve the problems of excessive dechlorination by-products and insignificant inhibition of dechlorination side reactions, and achieve the effects of avoiding the accumulation of hydroxylamine, good activity and selectivity, and not easy to be poisoned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

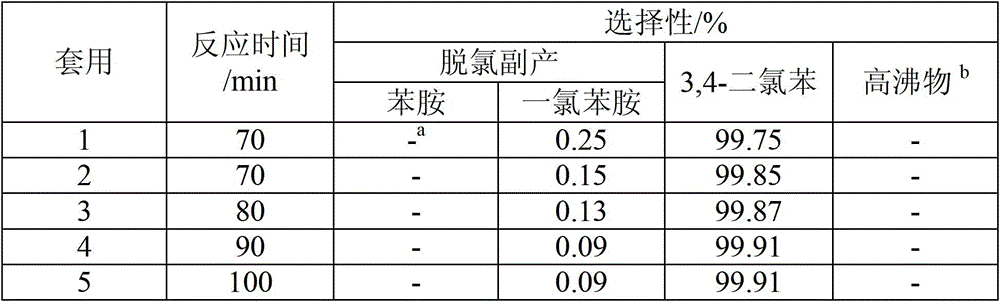

Examples

preparation example Construction

[0028] The preparation method of the catalyst: impregnating the carrier with a vanadium compound solution, washing, and drying; then impregnating the carrier impregnated with the vanadium compound solution in an aqueous solution of a palladium compound and a copper compound, and adjusting the pH value of the solution to alkaline with an alkali solution, and Use reducing agent to reduce treatment, filter and wash, and dry to obtain the catalyst.

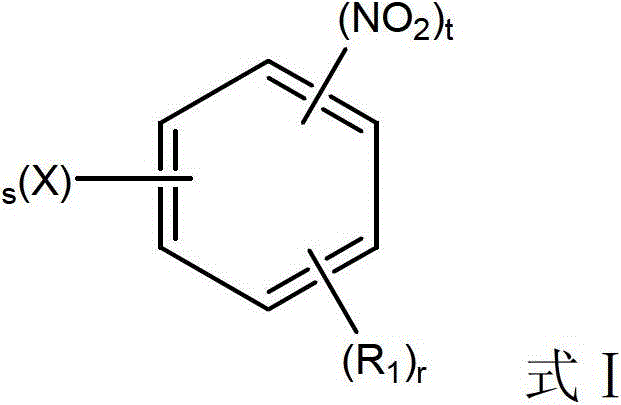

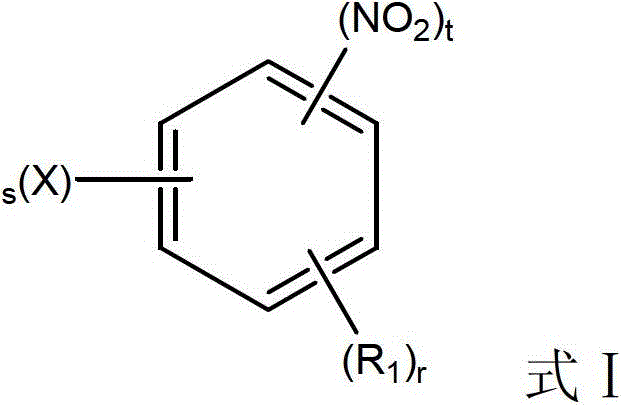

[0029] The catalyst is used for the catalytic hydrogenation of chlorinated aromatic nitro compounds to prepare chlorinated aromatic amines, wherein the structural formula of the chlorinated aromatic nitro compounds is shown in formula I:

[0030]

[0031] In the formula I, X=Cl; R 1 =H, R, NH 2 etc., wherein R is a C1-C8 alkane group; s, r, t represent numbers 1, 2 or 3, wherein s+r+t is less than or equal to 6.

Embodiment 1

[0033] Preparation of Pd-Cu-V / C Catalyst with 5% Pd Loading

[0034] Weigh 10.0g activated carbon (the specific surface area is 1000m 2 / g), added to 120mL distilled water stirred at a speed of 300 rpm. Add 50mL of vanadyl acetylacetonate in ethanol (containing 0.12gV) to the above suspension, keep it for 5h, filter and wash with water. Add the above treated activated carbon into 150mL of distilled water stirred at a speed of 300 rpm, slowly add 10mL of H 2 PdCl 4 solution (containing 0.5gPd), then slowly dropwise add 10mL copper acetate solution (containing 0.15gCu), stir for 6h, slowly add dropwise a sodium hydroxide solution with a mass content of 10% to adjust the pH to weakly alkaline (pH=8), and stir After 1h, the temperature was lowered to room temperature, filtered, and washed with water until neutral. After washing to neutrality, make a 150ml slurry at 30°C, then slowly add 2mL of 85% hydrazine hydrate solution dropwise, continue to stir for 2h, filter, wash with ...

Embodiment 2

[0036] Pd-Cu-V / C catalyst with 3% Pd loading

[0037] Weigh 10.0g activated carbon (the specific surface area is 1000m 2 / g), added to 120mL distilled water stirred at a speed of 300 rpm. Add 50ml of vanadyl acetylacetonate ethanol solution (containing 0.072gV) to the above suspension, keep it for 5h, filter and wash with water. Add the above treated activated carbon into 150 mL of distilled water stirred at 300 rpm, slowly add 6 mL of H 2 PdCl 4 solution (containing 0.3gPd), then slowly dropwise added 6mL copper acetate solution (containing 0.09gCu), stirred for 6h, slowly added dropwise a sodium hydroxide solution with a mass content of 10% to adjust the pH to weakly alkaline (pH=8), and stirred 1h, the temperature is lowered to room temperature, filtered, washed with water until neutral; after washing to neutral, make 150mL slurry at 30°C, then slowly add 2mL of 85% hydrazine hydrate solution dropwise, continue to stir for 2h, filter, wash with water , and dried to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com