A defibrating device for producing reconstituted tobacco leaves by dry papermaking

A technology of reconstituted tobacco leaves and dry papermaking, applied in tobacco, tobacco preparation, application, etc., can solve problems such as abnormal production, affecting fiber dispersion, and not very suitable for production, so as to improve environmental humidity, eliminate fiber agglomeration, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

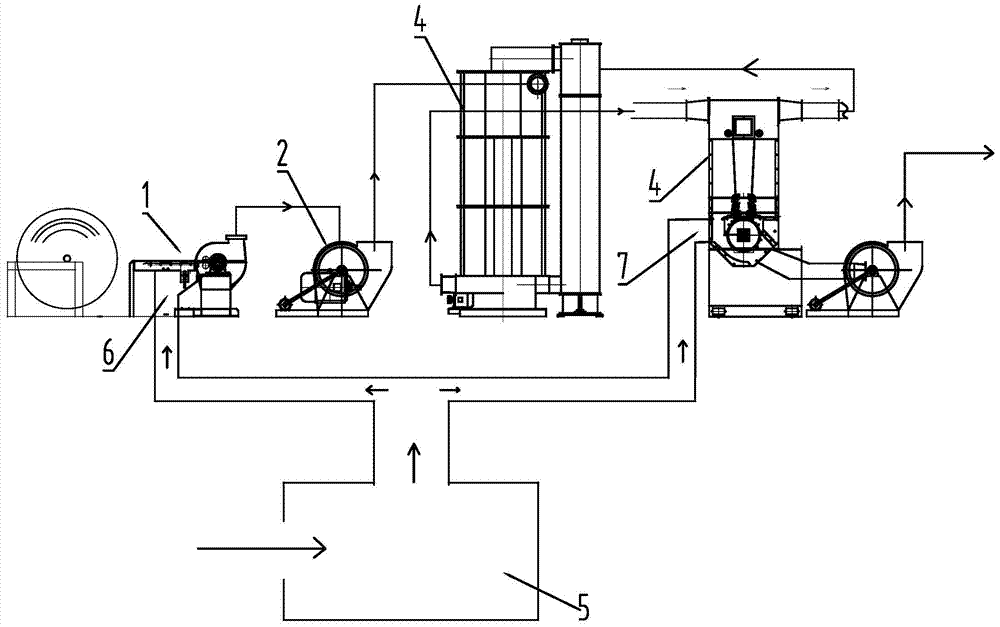

[0021] The humidity of the original operating environment is 28%, and the water is fully atomized with a high-pressure nozzle, filled with high-humidity air generator 5, and continuously replenished to keep the humidity in the loop above 80%, and no antistatic agent is used. Turn on the agitator in the fiber storage tank 3, the fine crusher 2, the coarse crusher 1 in sequence, and feed wood pulp to the material inlet 14. When the material level in the fiber storage tank 3 reaches the specified position, turn on the fiber counting machine 4 for metering and conveying The blower sends the wood pulp fiber to the fiber forming part along with the humidified air, and forms a dry-process reconstituted tobacco leaf base sheet containing 100% wood pulp fiber. There is no fiber agglomeration, pilling and wall hanging phenomenon caused by static electricity. No holes and broken edges, the weight is 30g / m 2 , Vertical and horizontal weight deviation <±5%.

Embodiment 2

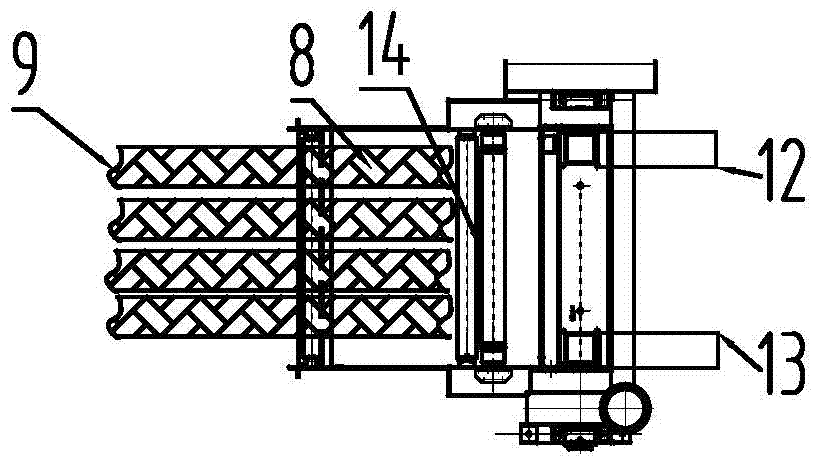

[0023] The ambient humidity is 35%, and the water vapor is fully atomized with a high-pressure nozzle, filled with high-humidity air generator 5, and continuously replenished to keep the humidity above 80%, without adding antistatic agent. Open fiber storage tank 3 agitator, fine crusher 2, coarse crusher 1 successively, feed wood pulp to material inlet 14, feed tobacco stem particles from granular material interface 13, two kinds of materials are according to technological formula (with Weight ratio) wood pulp 70%, tobacco stem particle 30%, adjust feed speed with frequency conversion device. When the material level in the fiber storage tank 3 reaches the specified position, turn on the metering and conveying fan of the fiber counting machine 4, and send the wood pulp fiber and tobacco stem fiber that are simultaneously defibrated and uniformly mixed to the fiber forming part with the humidified air, and formed It is the base sheet of dry-process reconstituted tobacco leaves ...

Embodiment 3

[0025] The ambient humidity is 30%, and the water vapor is fully atomized with a high-pressure nozzle, filled with high-humidity air generator 5, and continuously replenished to keep the humidity above 80%, without adding antistatic agent. Turn on the fiber storage tank 3 agitator, fine crusher 2, coarse crusher 1 in turn, feed wood pulp to the original feed port 14, feed hemp pulp from the fibrous material interface 12, and feed smoke from the granular material interface 13 Stem granule, three kinds of materials are according to technological proportioning (by weight) 40% of wood pulp, hemp pulp 30%, 30% of tobacco stem granule, adjust feeding speed respectively with frequency conversion. When the material level in the storage tank 3 reaches the specified position, turn on the metering and conveying fan of the fiber counting machine 4, and send the simultaneously defibrated and uniformly mixed wood pulp fibers, hemp pulp fibers and tobacco stem fibers to the forming part with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com