LED crystal covering structure coated with fluorescent powder and manufacturing method of LED crystal covering structure coated with fluorescent powder

A phosphor powder and LED chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of product life cycle, luminous efficiency impact, electrode wire heat dissipation volume is limited, heat dissipation effect is not obvious, etc., to achieve rapid light decay , Simplified packaging process and small internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with accompanying drawing:

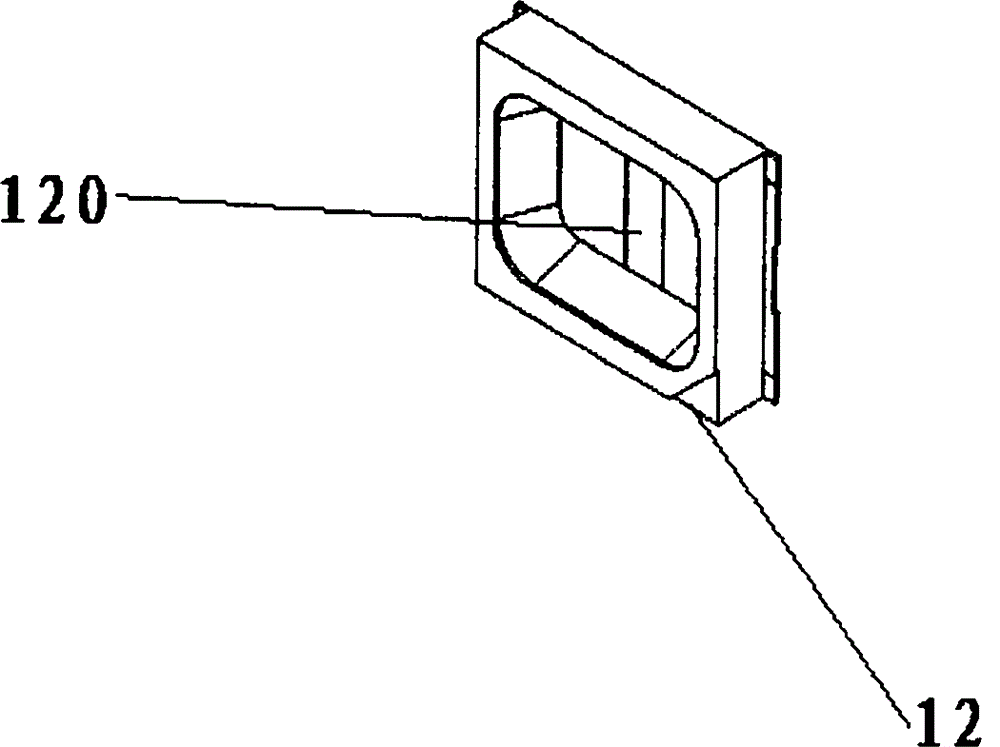

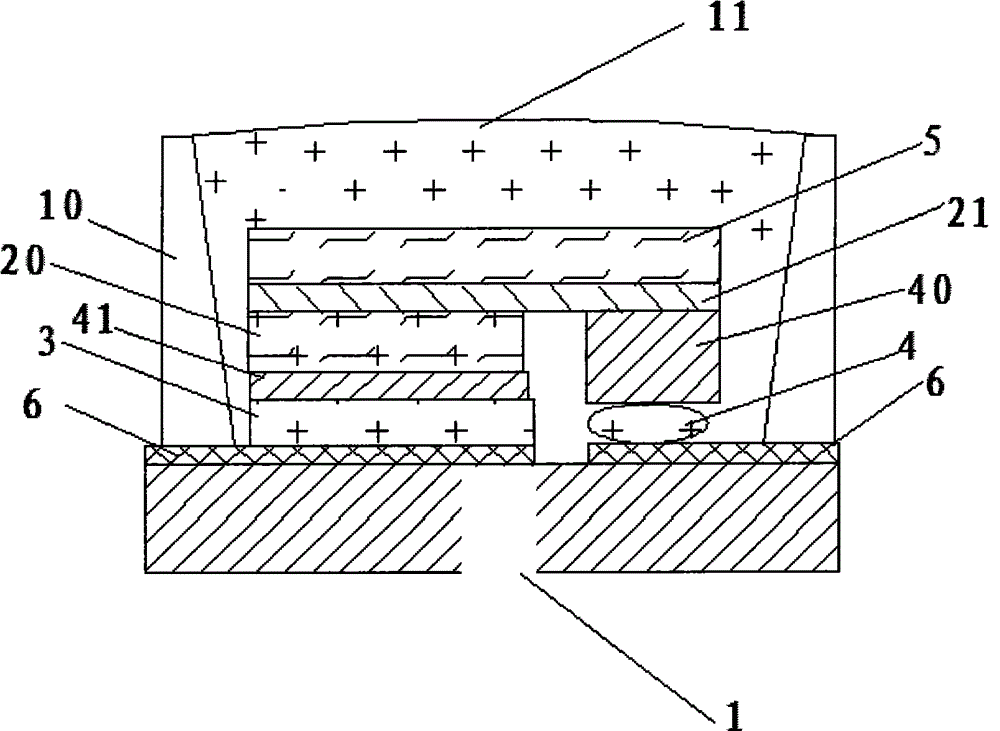

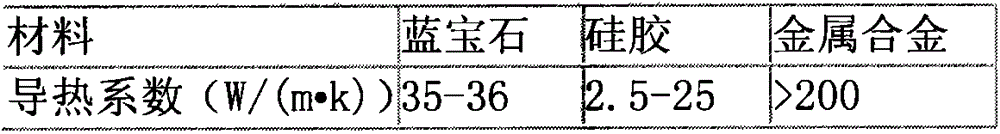

[0024] Such as figure 1 As shown, the present invention provides a LED flip-chip structure coated with phosphor powder, which includes a housing 10, a metal support 12, a substrate 1, an LED chip 2, a first electrode 3, a second electrode 4, a reflective layer 6 and The cover layer 5, the housing 10 is filled with fluorescent powder and silica gel 11, the upper end of the fluorescent powder 11 forms an arc-shaped surface, the reflective layer 6 is integrally formed on the substrate 1, and the LED chip includes a positive electrode 20 and a negative electrode 21. The electrode 20 is connected to the first electrode 3 , the negative electrode 21 is connected to the second electrode 4 , and the covering layer 5 is arranged on the top of the LED chip 2 . In this embodiment, the covering layer 5 is sapphire or other crystals. The material of the first electrode 3 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com