Manganese oxide/graphene porous microspheres, preparation method and energy storage application thereof

A technology of porous microspheres and graphene, which is applied in the manufacture of hybrid/electrical double layer capacitors, electrical components, battery electrodes, etc., can solve the problems of difficult mass production, long synthesis cycle, complicated steps, etc. , the effect of increased porosity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

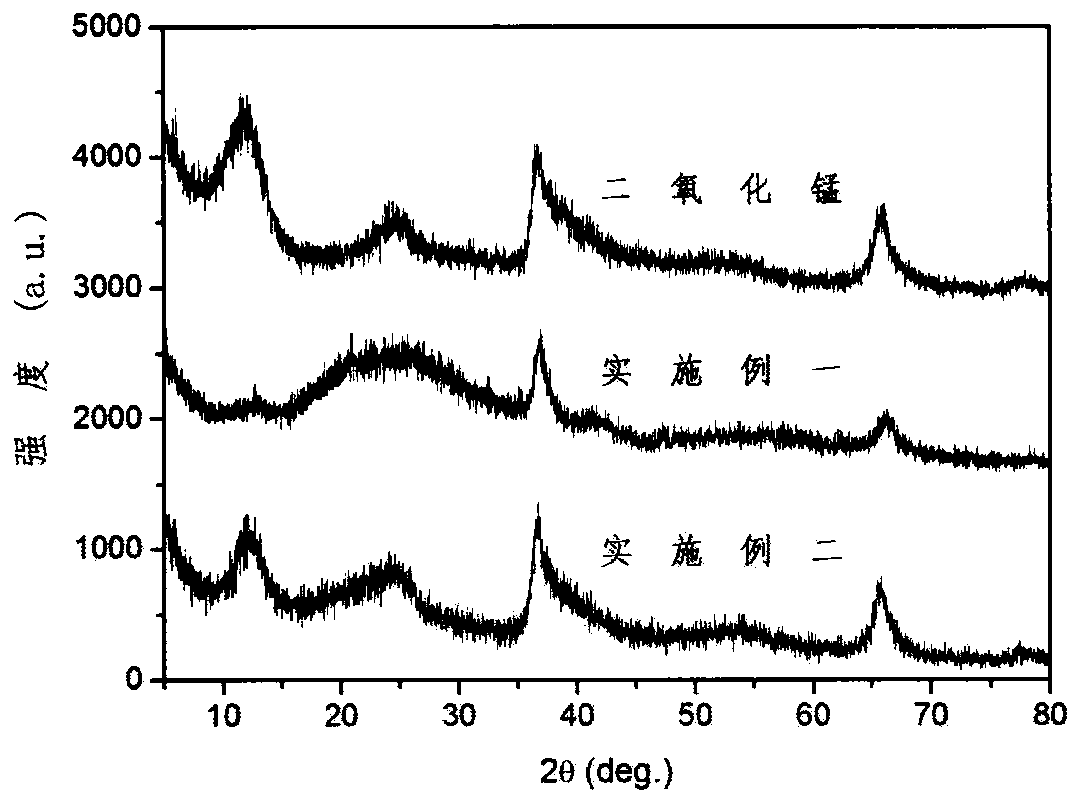

[0022] Example 1: Preparation of manganese dioxide / graphene porous microspheres using graphene oxide as a precursor

[0023] 0.12 g of graphite oxide was ultrasonically dispersed in distilled water for 30 minutes. After high-speed centrifugation for 10 minutes, the supernatant was taken to prepare a graphene oxide aqueous solution with a concentration of 0.56 mg / ml, and a small amount of ammonia water was added dropwise to adjust the pH value to neutral. Slowly add an appropriate amount of nano-manganese dioxide particle suspension into the graphene oxide solution (the mass ratio of graphene oxide / manganese dioxide is 1:4) under stirring, then raise the temperature to 50° C. and continue stirring for 1 h. The resulting mixed solution was spray dried with an inlet temperature of 125°C and an outlet temperature of 40°C. The collected solid powders were sequentially dried at 80° C. and 250° C. for 2 hours respectively to obtain a trimanganese dioxide / graphene composite material....

Embodiment 2

[0024] Example 2: Preparation of manganese dioxide / graphene porous microspheres using reduced graphene as a precursor

[0025] 0.25 g of graphite oxide was ultrasonically dispersed in distilled water for 30 minutes, centrifuged at high speed for 10 minutes, and the supernatant was taken to prepare a graphene oxide solution with a concentration of 0.05 wt.%. Add 2.5 ml of 80% hydrazine hydrate and 21 ml of 25% ammonia solution in sequence. After magnetic stirring for 12 h, the solution was dialyzed several times in 0.5% ammonia solution to remove hydrazine hydrate, resulting in a stable reduced graphene suspension. Add an appropriate amount of nano-manganese dioxide particle suspension into the graphene solution (the mass ratio of reduced graphene / manganese dioxide is 1:9), stir magnetically for 30 minutes, and disperse ultrasonically for 30 minutes. The obtained mixed solution was spray-dried under the same conditions. Continue drying the collected solid at 80° C. for 2 hour...

Embodiment 3

[0026] Example 3: Using reduced graphene as a precursor to prepare trimanganese tetraoxide / graphene composite porous microspheres

[0027] 0.25 g of graphite oxide was ultrasonically dispersed in distilled water for 30 minutes, centrifuged at high speed for 10 minutes, and the supernatant was taken to prepare a graphene oxide solution with a concentration of 0.05 wt.%. Add 2.5 ml of 80% hydrazine hydrate and 21 ml of 25% ammonia solution in sequence. After magnetic stirring for 12 h, the solution was dialyzed several times in 0.5% ammonia solution to remove hydrazine hydrate, resulting in a stable reduced graphene suspension. Add an appropriate amount of nanometer manganese tetraoxide particle suspension into the graphene solution (reduced graphene / manganese tetraoxide mass ratio is 1:9), magnetically stir for 30 minutes, and then ultrasonically disperse for 30 minutes. The obtained mixed solution was spray-dried under the same conditions. Continue drying the collected solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com